Resistance heating type melt-drawn machine for manufacturing optical fiber devices

A technology of resistance heating and optical fiber devices, applied in the coupling of optical waveguides, etc., to achieve safe use, adjustable heating temperature, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention will be described below with reference to the accompanying drawings.

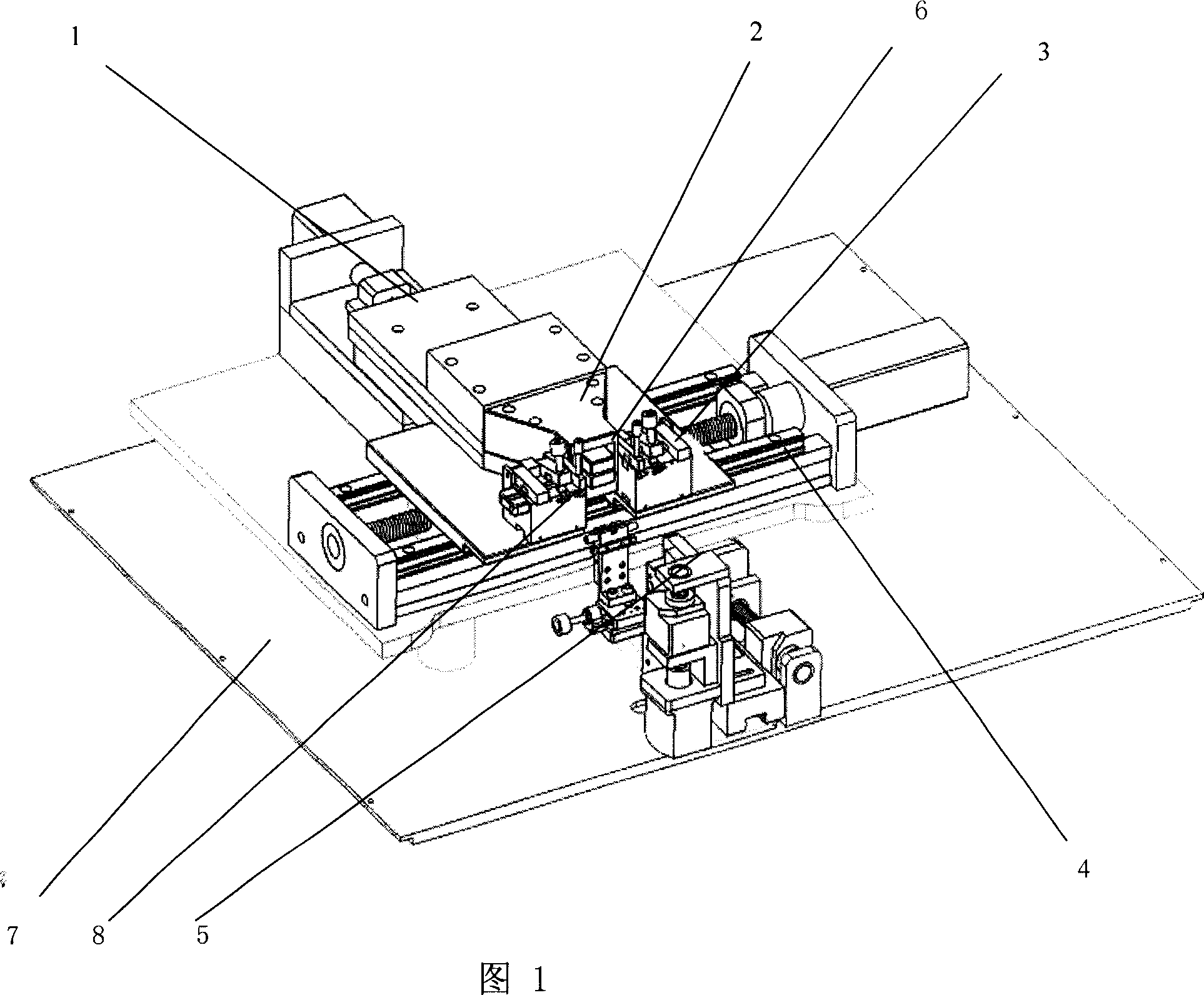

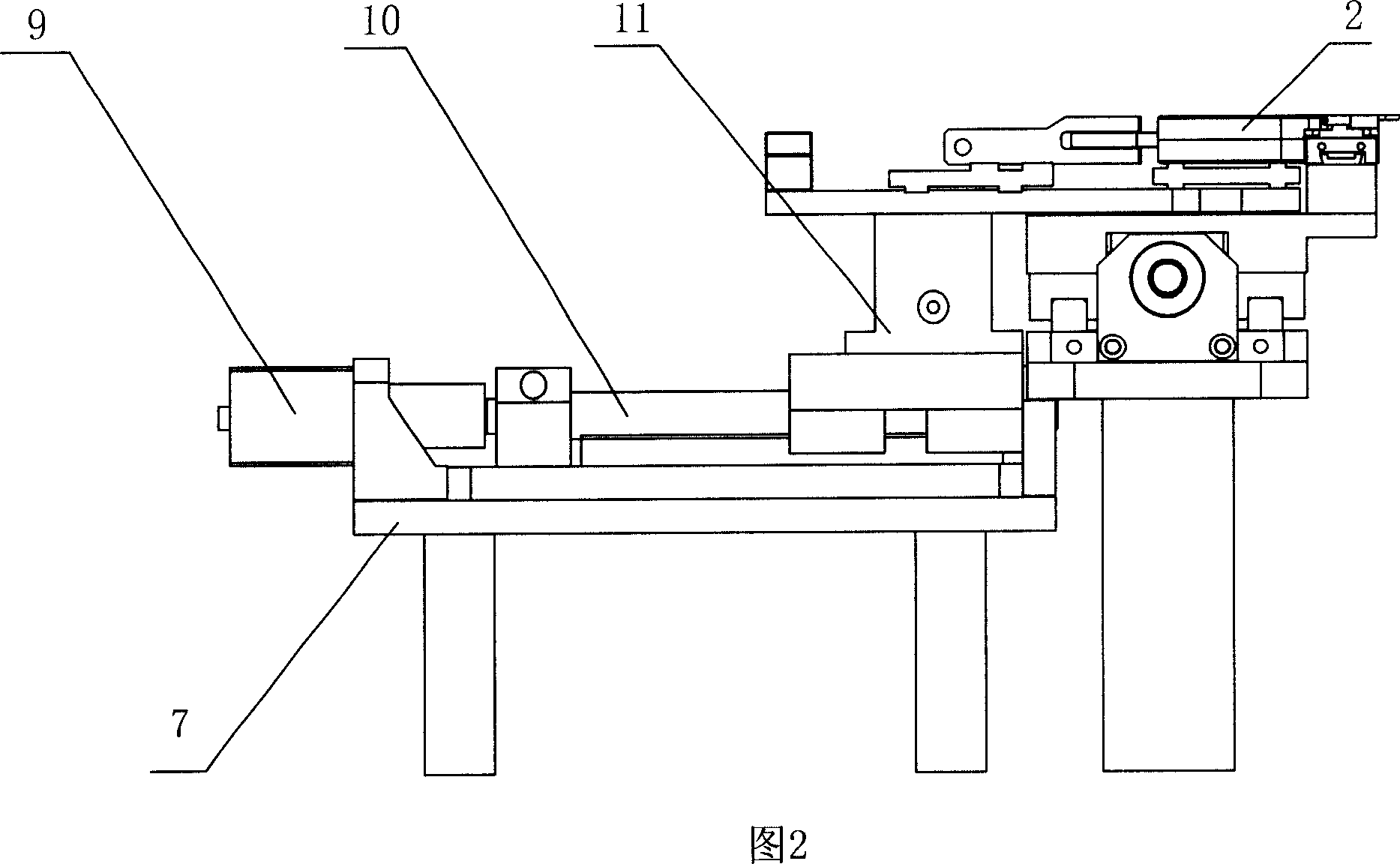

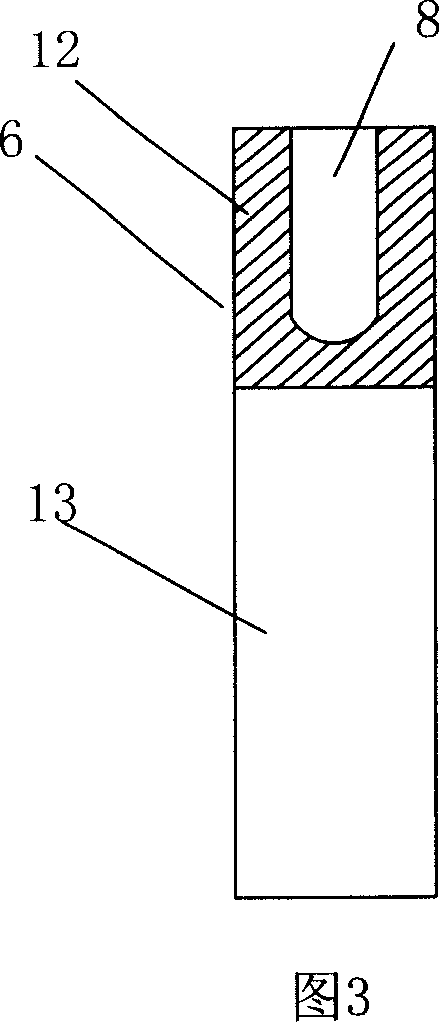

[0034] Referring to Figure 1, Figure 2, Figure 3 and Figure 4, an optical fiber drawing mechanism 4 is provided on the frame 7, an optical fiber clamp 3 is provided on the optical fiber drawing mechanism 4, and an optical fiber packaging mechanism 5 is provided on the frame 7 The heater movement mechanism 1 is provided on the frame 7, the resistance heater 2 is provided on the heater movement mechanism 1, the heater 2 is provided with a resistance heating element 6, and the front end of the resistance heating element 6 is provided with an optical fiber clamp 3 Corresponding to the heating tank 8, the resistance heating element 6 is electrically connected with a temperature control device.

[0035] The heater movement mechanism 1 is composed of a manual lifting adjustment device 11 and an automatic feeding device 10, which is arranged on the frame 7, the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com