Use of a pigment composition comprising mixed crystals based on CI pigment yellow 74

A technology of pigment composition and mixed crystals, which can be applied in applications, organic dyes, household appliances, etc., and can solve problems such as adverse effects on applicability, use of undescribed pigment mixtures, nozzle clogging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

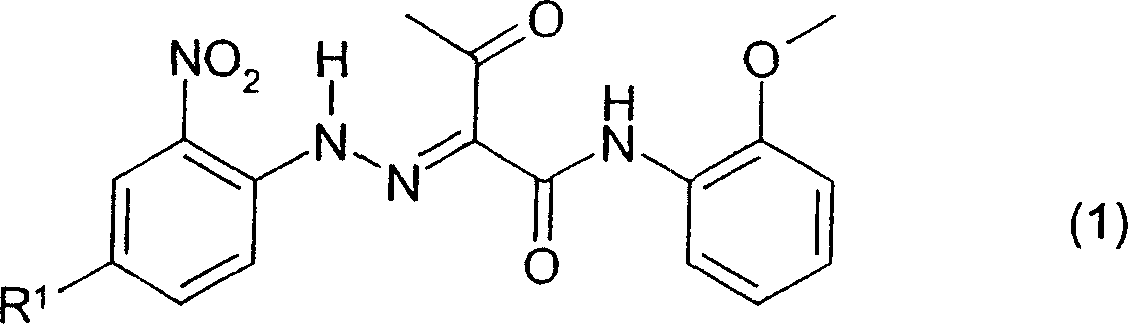

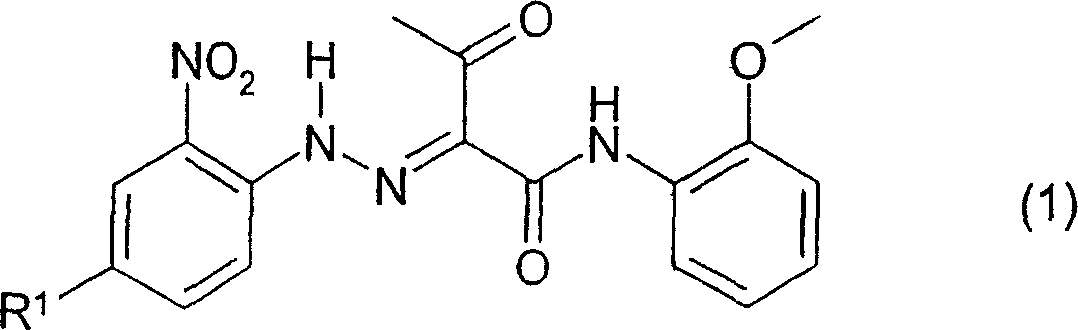

[0043] 90 total mole % C.I. Pigment Yellow 74 and 10 total mole % C.I. Pigment Yellow 65

[0044] a) Diazo

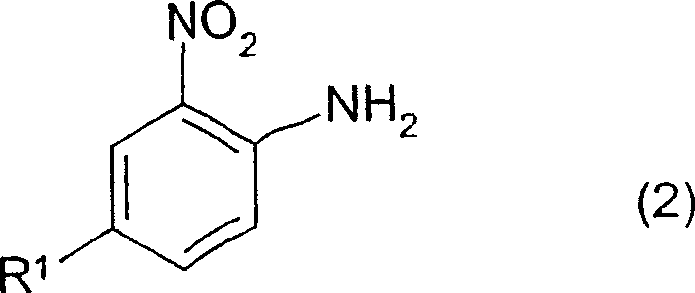

[0045] 121.1 parts of 5-nitro-2-aminoanisole and 13.5 parts of 3-nitro-4-aminoanisole were slurried in 336 parts of water and 188 parts of 31% strength hydrochloric acid. The suspension is cooled to 0° C. with 672 parts of an ice / water mixture and diazotized by adding 107.8 parts of a 40% strength sodium nitrite solution. by adding 1.92 parts The diazonium solution was clarified by Decalite and then filtered.

[0046] b) Coupler

[0047] 165.8 parts of o-anisidine acetoacetate were dissolved in 2152 parts of water and 94.1 parts of 33% sodium hydroxide solution. Cooling to 10° C. was carried out with the addition of ice, the coupler was precipitated with 80 parts of 80% strength acetic acid, and the product was adjusted to a pH of 9.8 using 33% strength sodium hydroxide solution.

[0048] c) Coupling

[0049] The diazo solution was added to the coupler within on...

Embodiment 2

[0084] 93 total mole % C.I. Pigment Yellow 74 and 7 total mole % C.I. Pigment Yellow 65

[0085]The synthesis was carried out analogously to Example 1, except that 125.1 parts of 5-nitro-2-aminoanisole and 9.4 parts of 3-nitro-4-aminoanisole were used. A mixture of mixed crystals is obtained.

Embodiment 3

[0087] 95 total mole % C.I. Pigment Yellow 74 and 5 total mole % C.I. Pigment Yellow 65

[0088] The synthesis was carried out analogously to Example 1, except that 127.8 parts of 5-nitro-2-aminoanisole and 6.7 parts of 3-nitro-4-aminoanisole were used. A mixture of mixed crystals is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com