Method for manufacturing elliptically polarizing plate and image display device using the elliptically polarizing plate

A technology of ellipsoidal polarization and polarizer, applied in the direction of identification devices, optics, optical components, etc., can solve the problems that have not yet found a widely applicable method, difficult to adjust, etc., and achieve the optimization of ellipsoidal polarizer, excellent adhesion, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

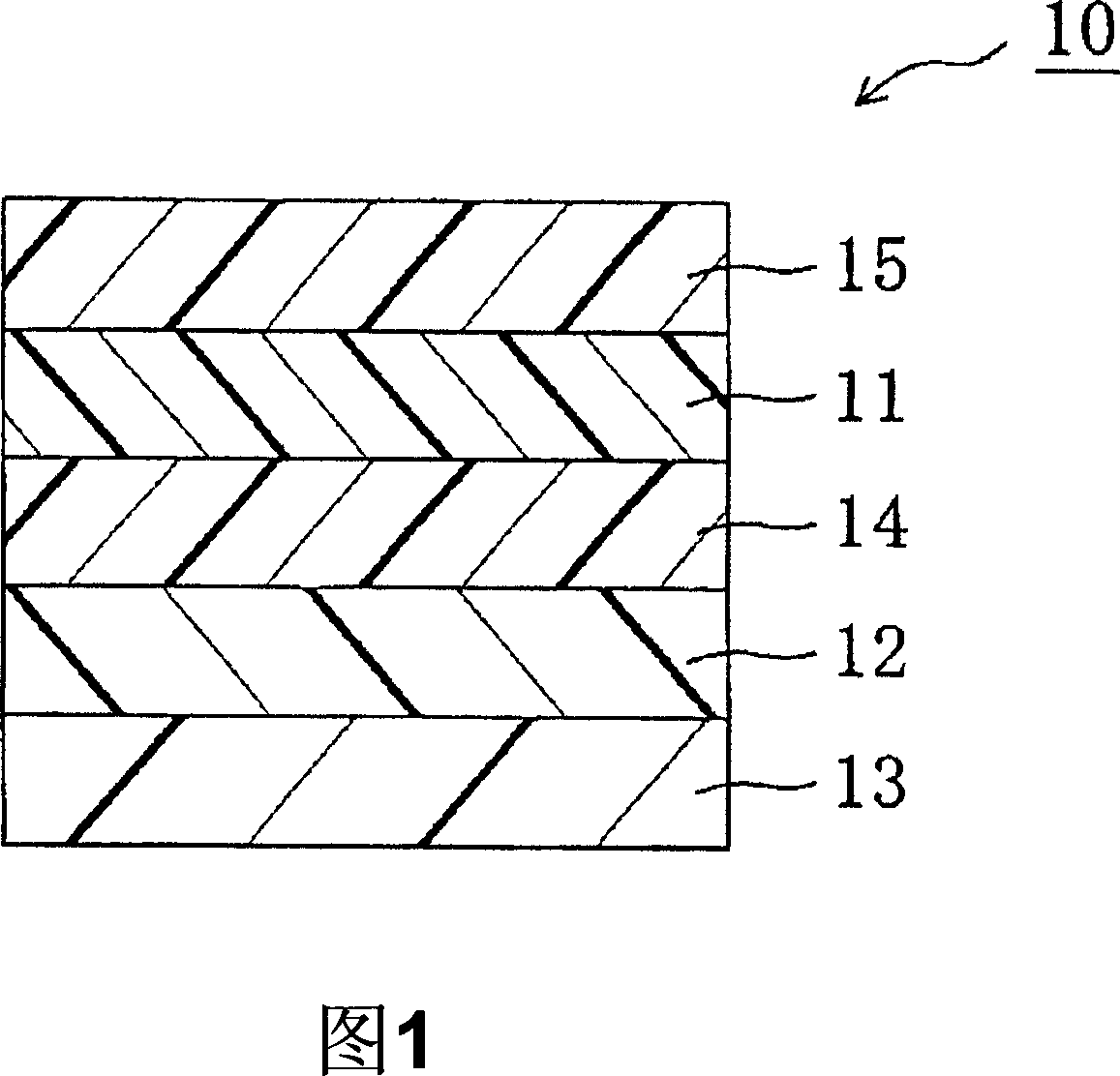

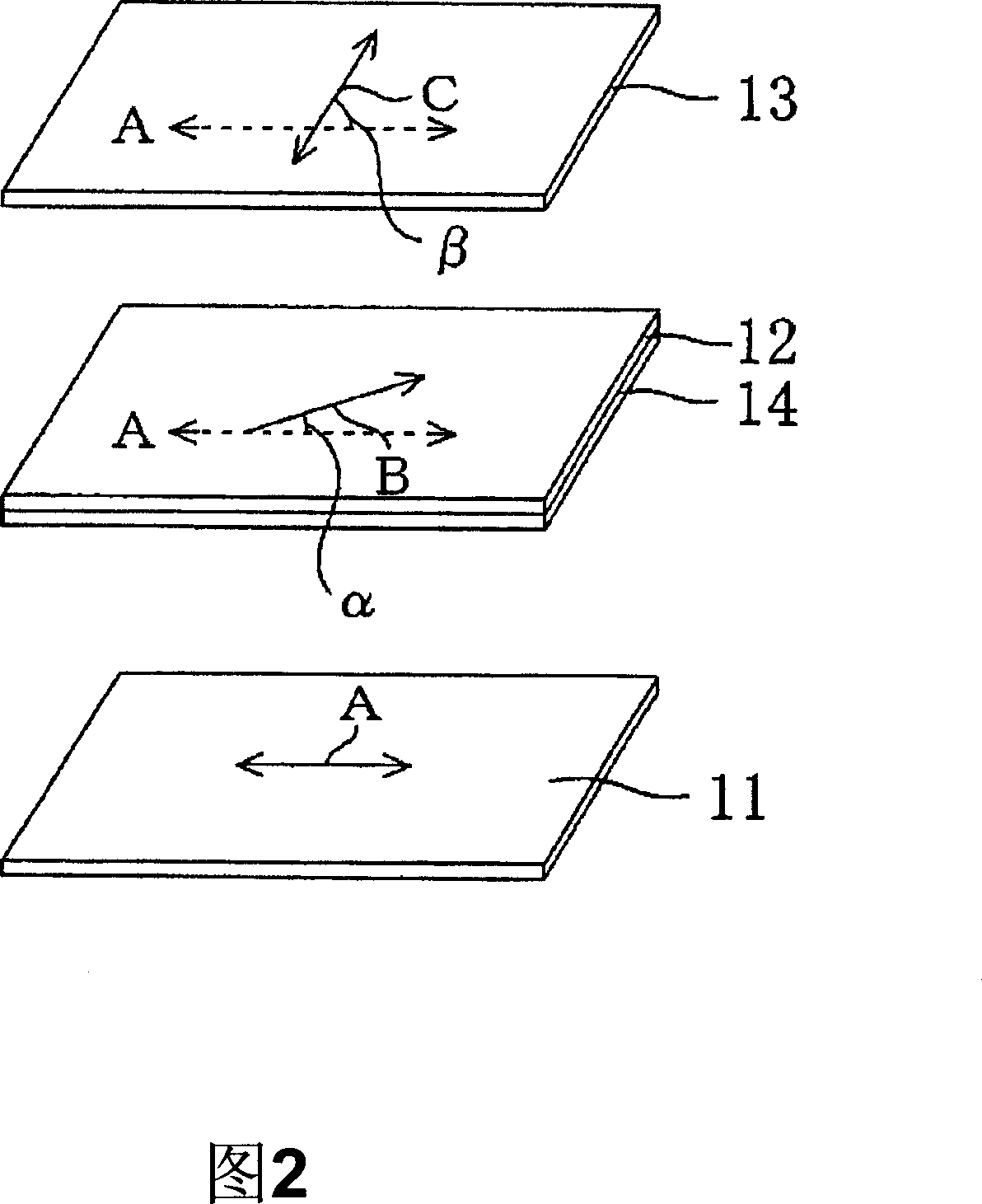

[0169] I. prepare the elliptical polarizer as shown in Figure 1

[0170] I-a. Alignment treatment of substrate (preparation of alignment substrate)

[0171] Alignment treatment is performed on the substrate to prepare an alignment substrate.

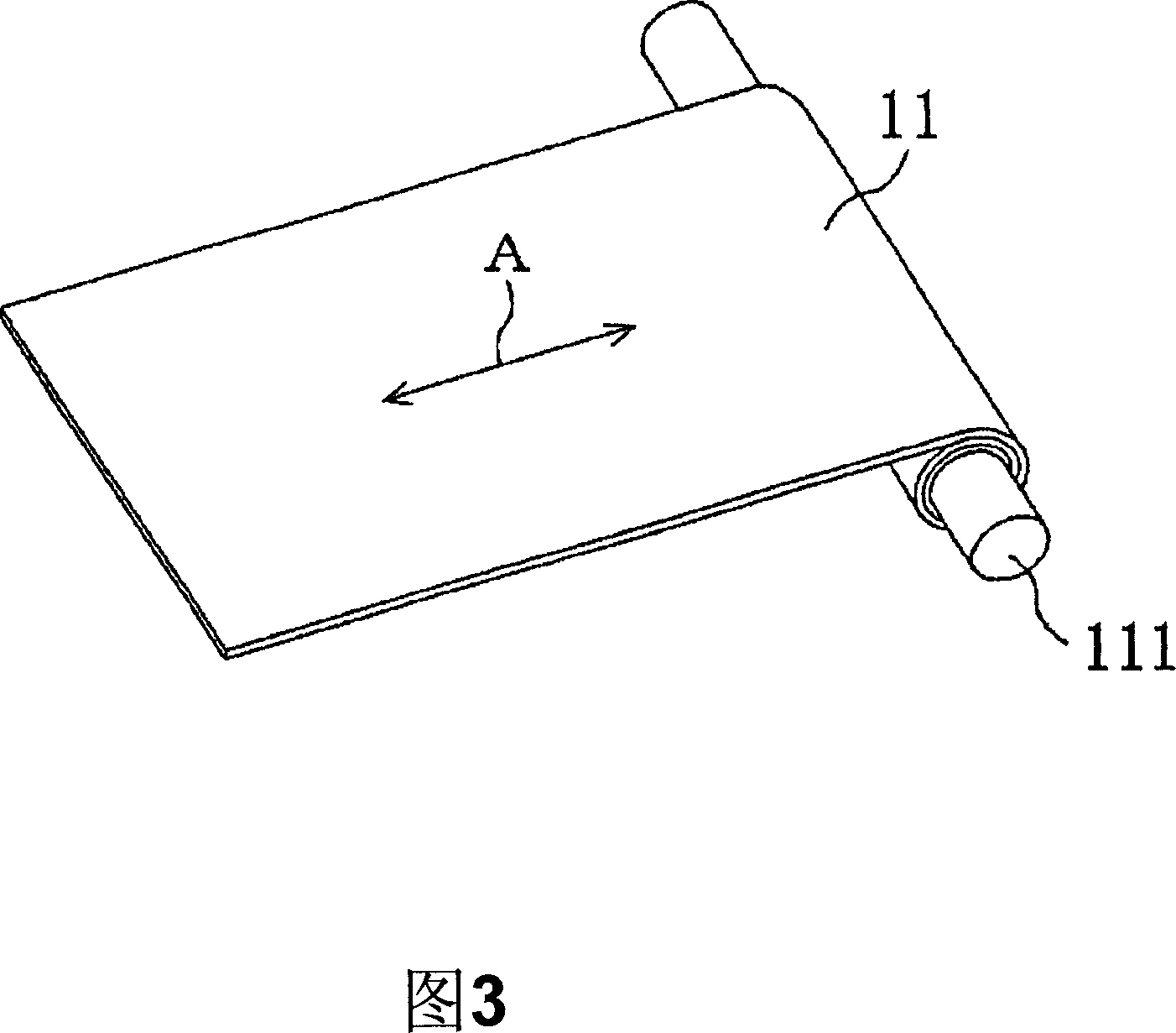

[0172] Substrates (1) to (6): Each alignment substrate was formed by rubbing the surface of a polyethylene terephthalate (PET) film (50 μm in thickness) with a rubbing cloth at the rubbing angle shown in Table 1 below.

[0173] Substrate

Friction angle (angle α)

(1)

13°

(2)

-13°

(3)

23°

(4)

-23°

(5)

33°

(6)

-33°

[0174] I-b. Preparation of the first birefringent layer (the first birefringent layer formed on the substrate)

[0175] 10 g of a polymerizable liquid crystal exhibiting a nematic liquid crystal phase (Paliocolor LC242, trade name; purchased from BASF Group Corporation) and 3 g of a photopolymerization initiator for a...

Embodiment 2

[0192] The elliptically polarizing plate A01 was overlaid to measure the contrast. Table 1 shows that elliptically polarizing plates have a relationship represented by the expression β=2α+44°. For this elliptical polarizer, when the contrast ratio is 10, the minimum angle in all directions is 40°, the maximum angle is 50°, and the difference between the maximum and minimum angles is 10°. In actual use, when the contrast ratio in all directions is 10, the minimum angle of 40° is the preferred level. Moreover, the difference between the maximum and minimum angles is only 10°, so the elliptical polarizer has balanced visual characteristics, which is also a very preferable level in practical use.

Embodiment 3

[0194] The elliptically polarizing plate A21 was overlaid to measure the contrast. Table 1 shows that elliptically polarizing plates have a relationship represented by the expression β=2α+44°. For this elliptical polarizer, when the contrast ratio is 10, the minimum angle in all directions is 40°, the maximum angle is 60°, and the difference between the maximum and minimum angles is 20°. In actual use, when the contrast ratio in all directions is 10, the minimum angle of 40° is the preferred level.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com