Processing technology for composite slide

A processing technology and technology of slide glass, which is applied in the field of processing technology of composite slide glass, can solve the problems of long time, high cost, difficulty in controlling the depth and size of the bottom of the groove, etc., and achieve the effect of cost saving and short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

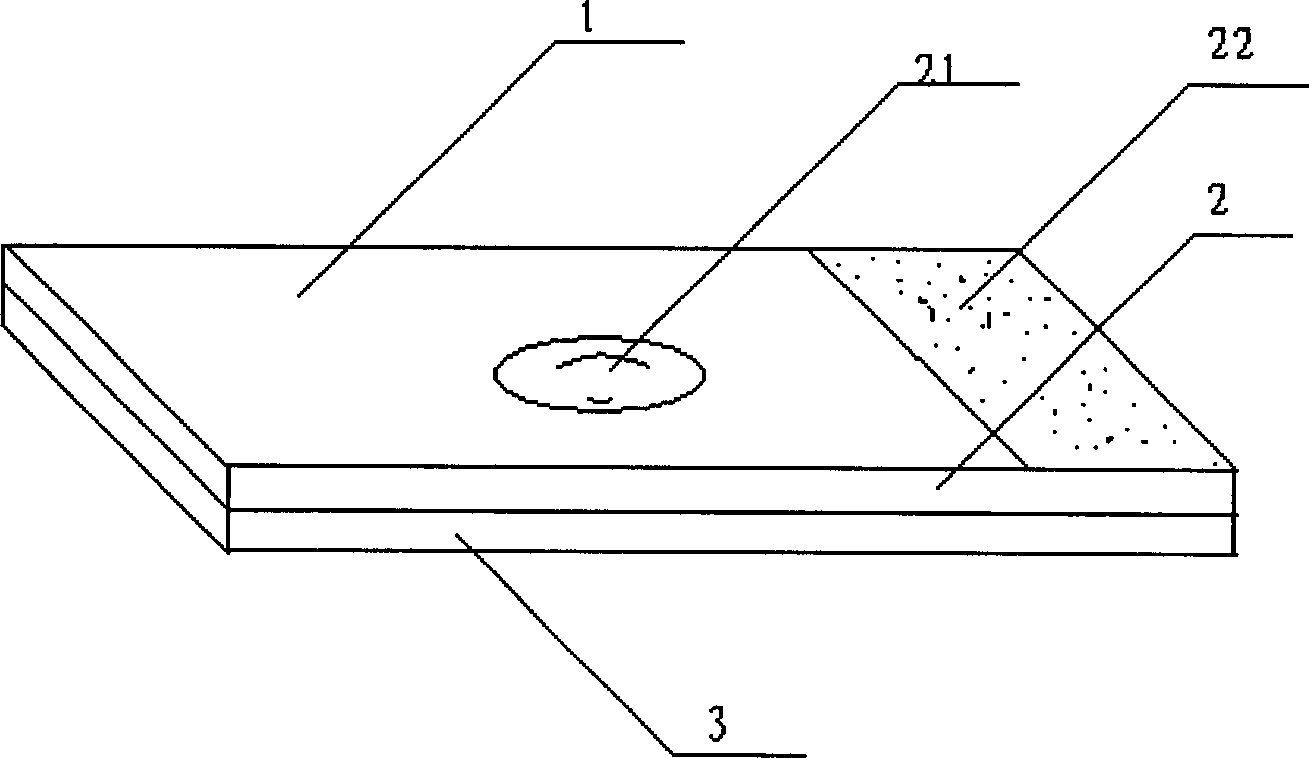

[0025] As shown in the figure, take a flat glass slide 2, process a round hole 21 on it, and coat one side thereof; process the other flat glass slide into a flat glass slide 3 with uniform thickness;

[0026] Combining the above two flat glass slides together by means of hot pressing to obtain a composite glass slide.

[0027] One end of the flat glass slide with a hollow hole is processed into a foggy surface 22, on which data can be directly recorded.

Embodiment 2

[0029] As shown in the figure, take a flat glass slide 2, process a round hole 21 on it, and coat one side thereof; process the other flat glass slide into a flat glass slide 3 with uniform thickness;

[0030] The above two flat glass slides are combined together by optical gluing, that is, the surface of the glass slides is cleaned first, then coated with cold glue, and then cured with ultraviolet rays to obtain a composite glass slide, in which the coated side is in contact with the other flat glass side. combined.

[0031] One end of the flat glass slide with a hollow hole is processed into a foggy surface 22, on which data can be directly recorded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com