Multifunctional orthopedic operation equipment and its automatic control method

A kind of surgical equipment and multi-functional technology, applied in the direction of surgery, application, surgical saw, etc., can solve the problems of patient danger, speed switching error, equipment damage, etc., achieve accurate recognition performance, long service life, and reduce working pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings.

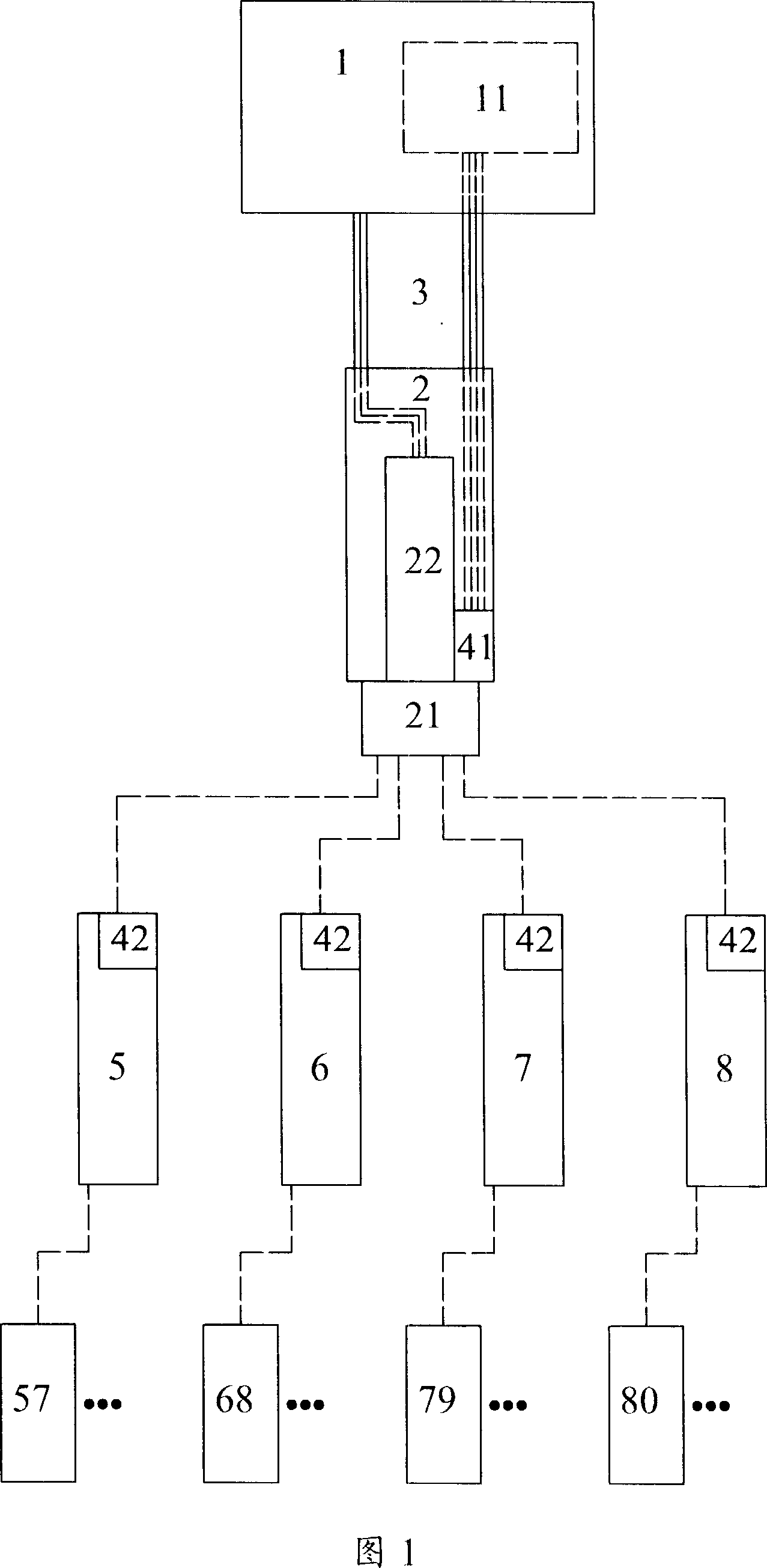

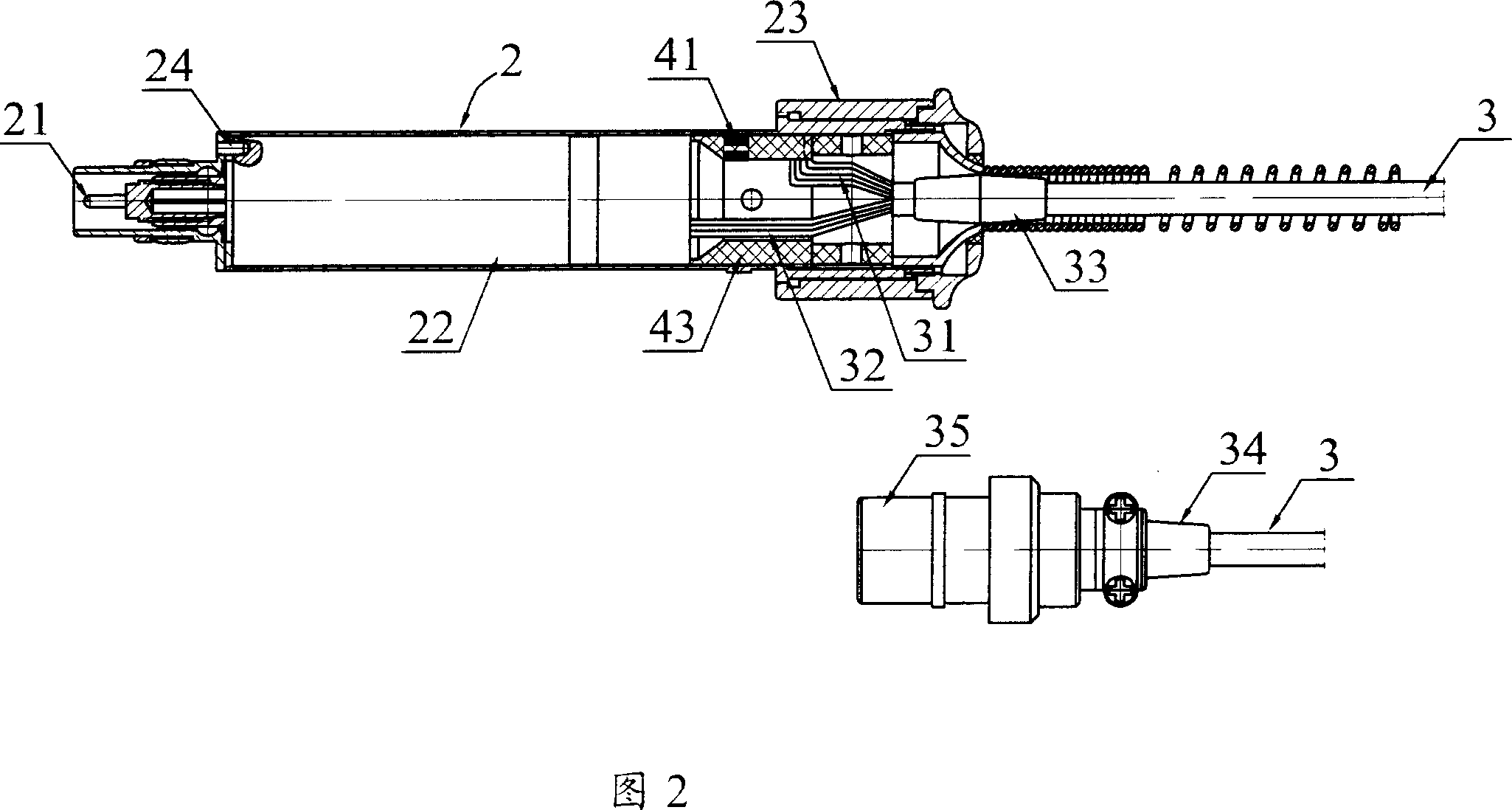

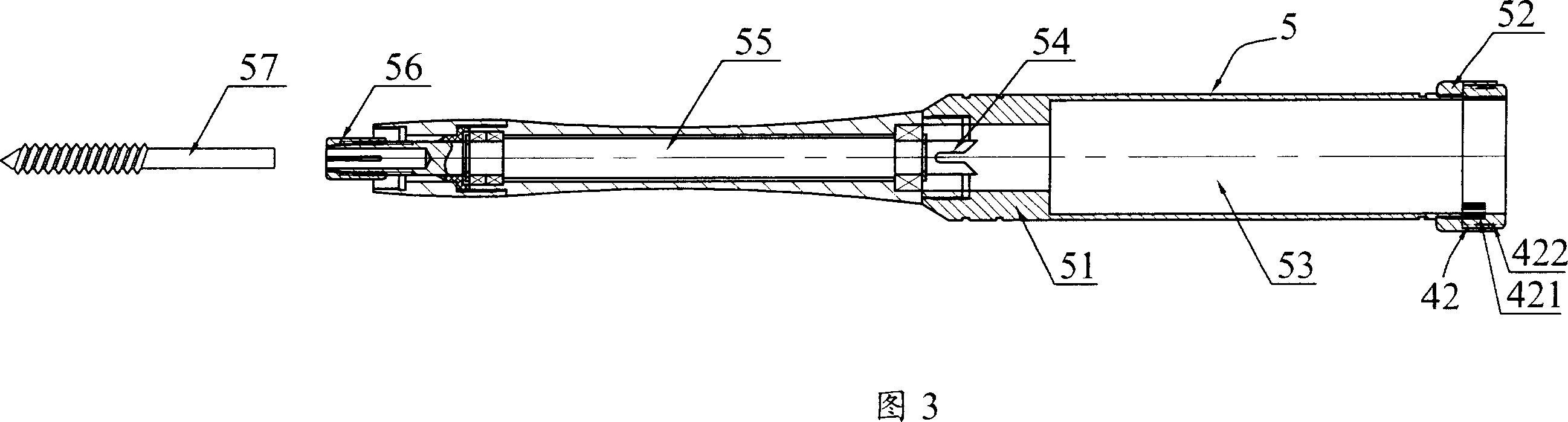

[0041] As shown in Figure 1, the present invention has designed a kind of multifunctional surgical equipment for orthopedics, which is characterized in that it includes: a host 1 for providing power and automatic control; a high-speed motor core 2 for driving and identifying tool handles , the motor core 2 is connected to the host machine 1 through a cable 3, and the cable 3 includes at least a signal transmission line 31 and a power drive line 32; four tool handles 5, 6, 7 that generate different motion mechanisms under the drive of the high-speed motor core 2 And 8, the tool handle 5, 6, 7 and 8 front ends are tool head mounting ends, and the rear end is a shell that is socketed and installed with the motor core 2, and the inside of the shell is provided with a drive end 21 that matches the motor core 2. The transmission structure, the transmission structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com