Floor drain for co-layer draining

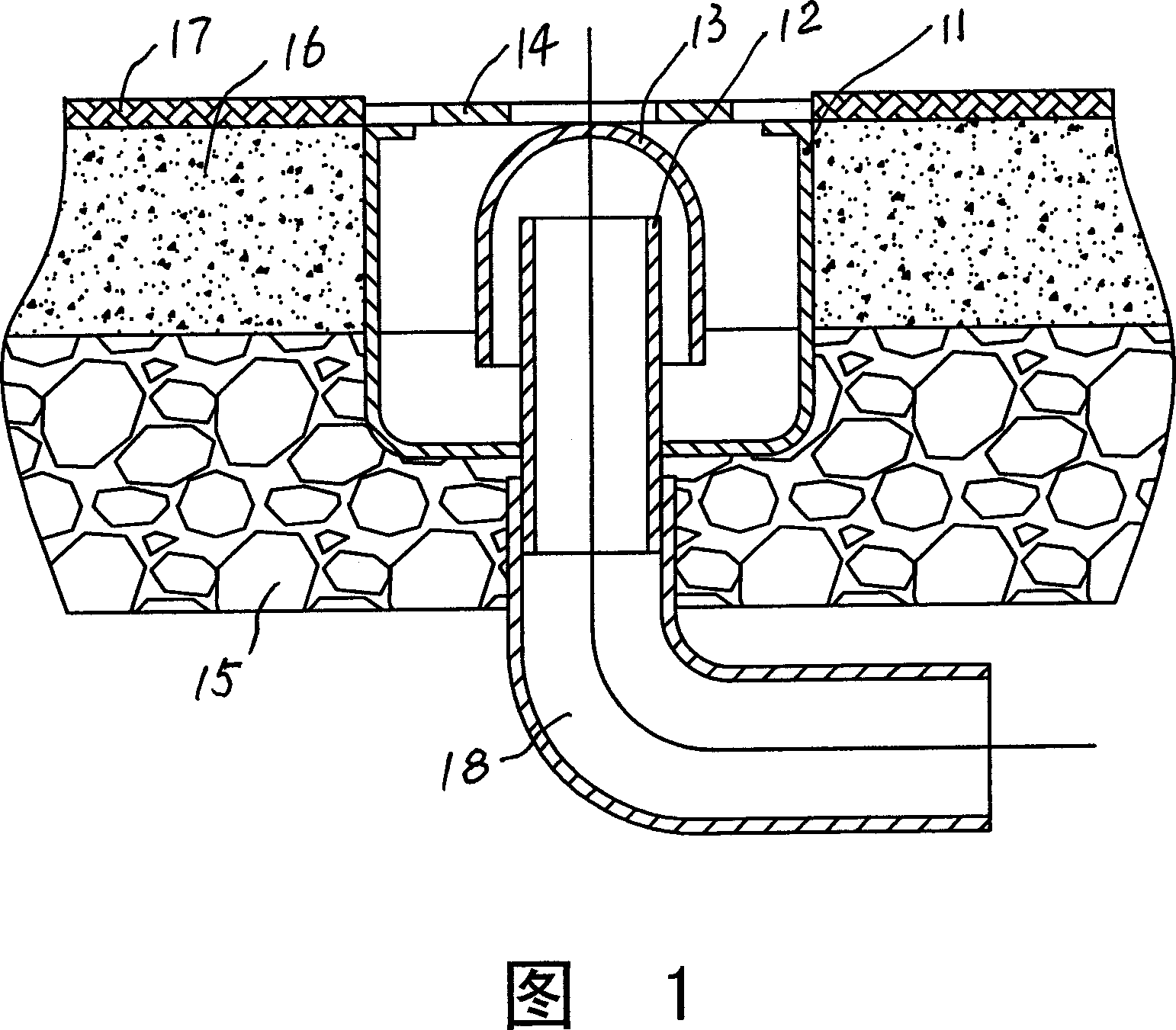

A technology for drainage and drainage funnels on the same floor, applied in water supply installations, indoor sanitary piping installations, buildings, etc., can solve the problems of complicated installation, high total floor drain height, insufficient water seal height and water storage capacity, etc. The effect of increased net height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

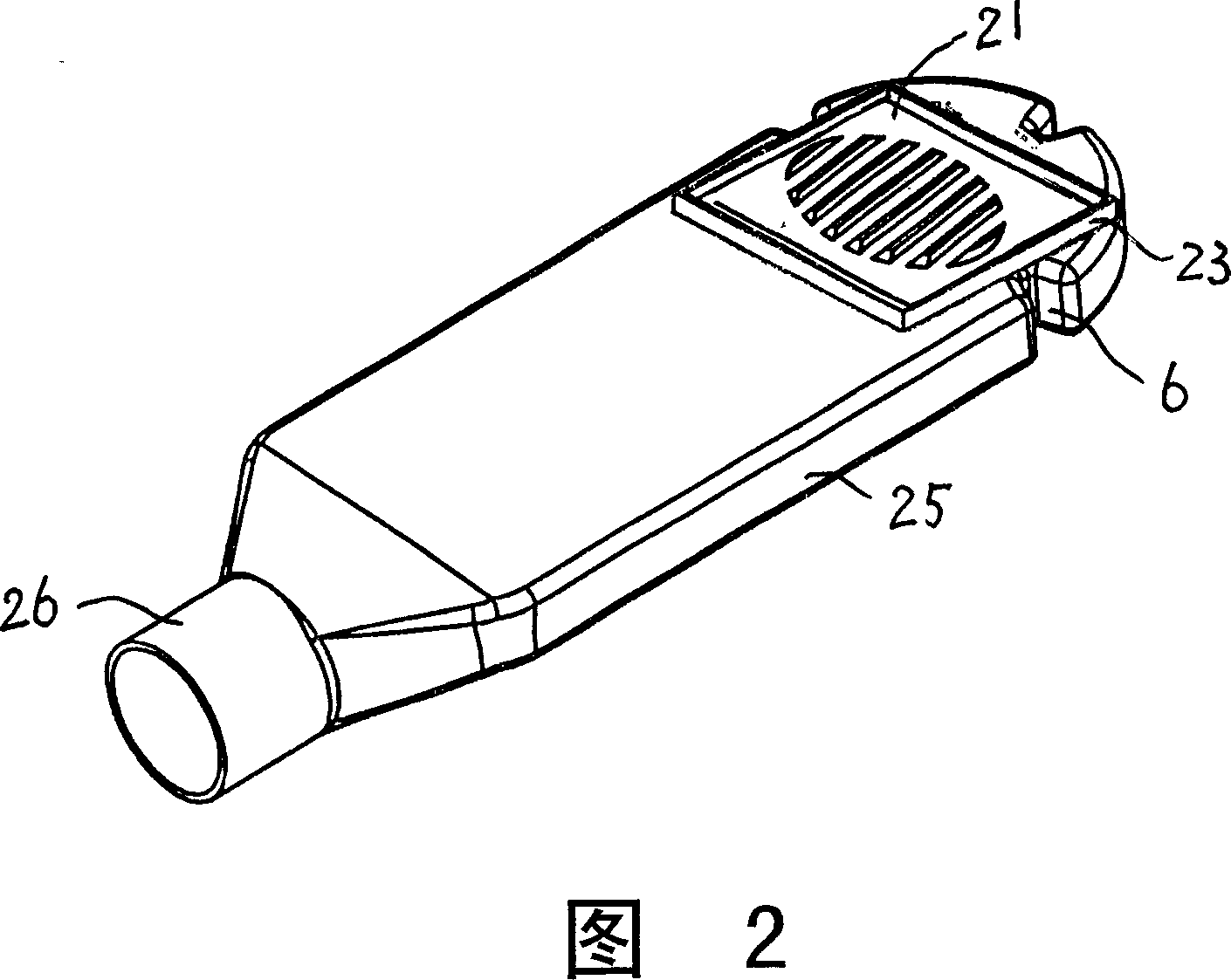

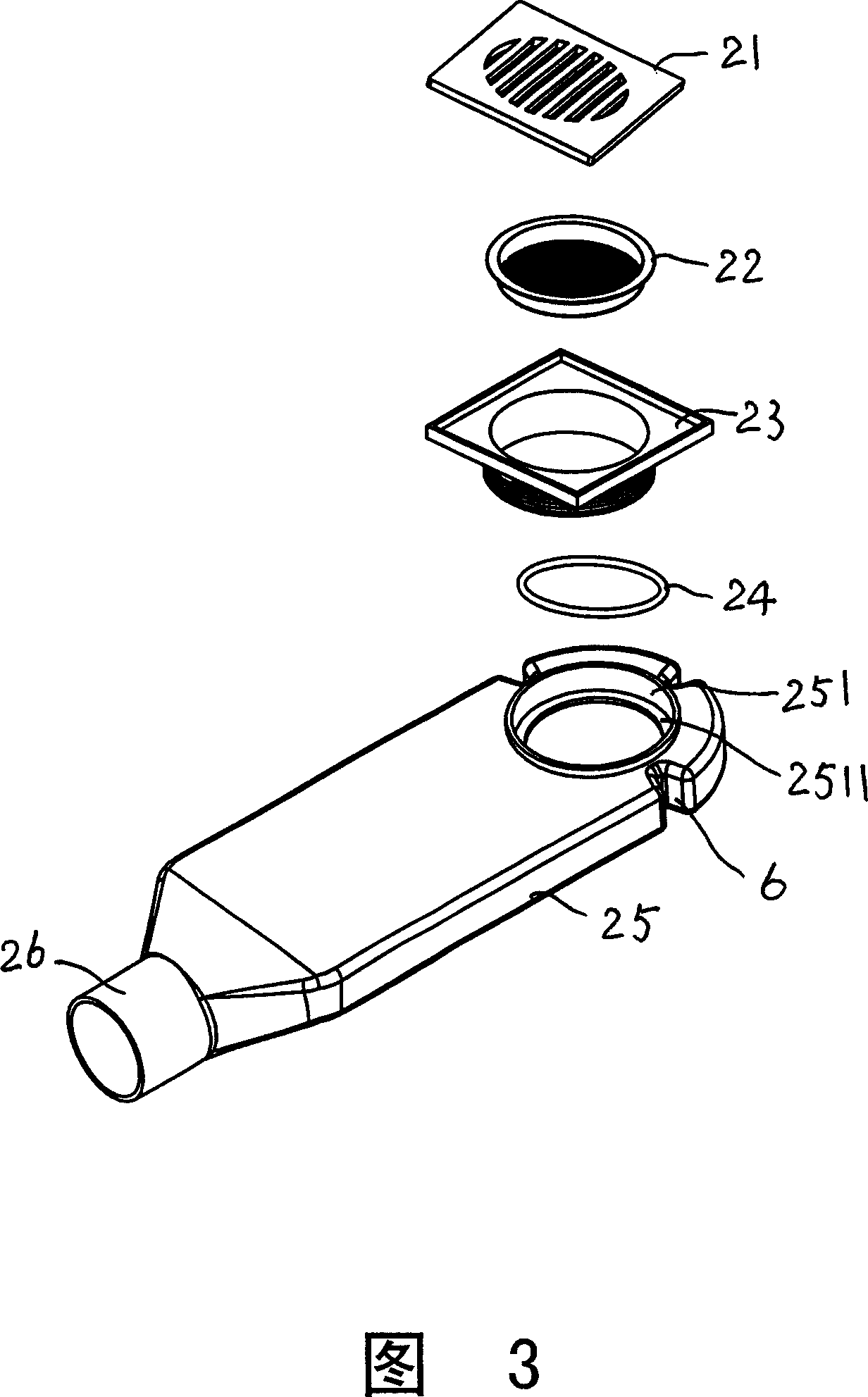

[0025] Please refer to Figure 2 to Figure 4. The present invention is a floor drain for draining water on the same floor, comprising: a grid cover plate 21 , a filter screen 22 , a drain funnel 23 , an O-shaped sealing ring 24 , and a floor drain body 25 . The grille cover plate 21 and the filter screen 22 jointly filter hair and sundries in the water. The floor drain body 25 is a hollow flat tray structure. The height of the floor drain body 25 designed in this embodiment is very low, only about 30mm, which does not affect water leakage, and takes up little ground thickness, which is convenient for installation on the same floor. The front end of the top of the floor drain body is provided with a water inlet hole 251, and the grid cover plate 21, the filter screen 22, the drainage funnel 23, and the O-shaped sealing ring 24 are sequentially seated on the water inlet hole; wherein: the described The water inlet hole of the floor drain body is a sunken tray structure, and its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com