Bridge stuffing hard connecting impact type ignitor

A hard-connected, impact-type technology, used in ignition devices, gas well packers, and oil well fields, it can solve problems such as casing collision and friction, inability to implement cable bridge plug seat sealing operations, and cable rework.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

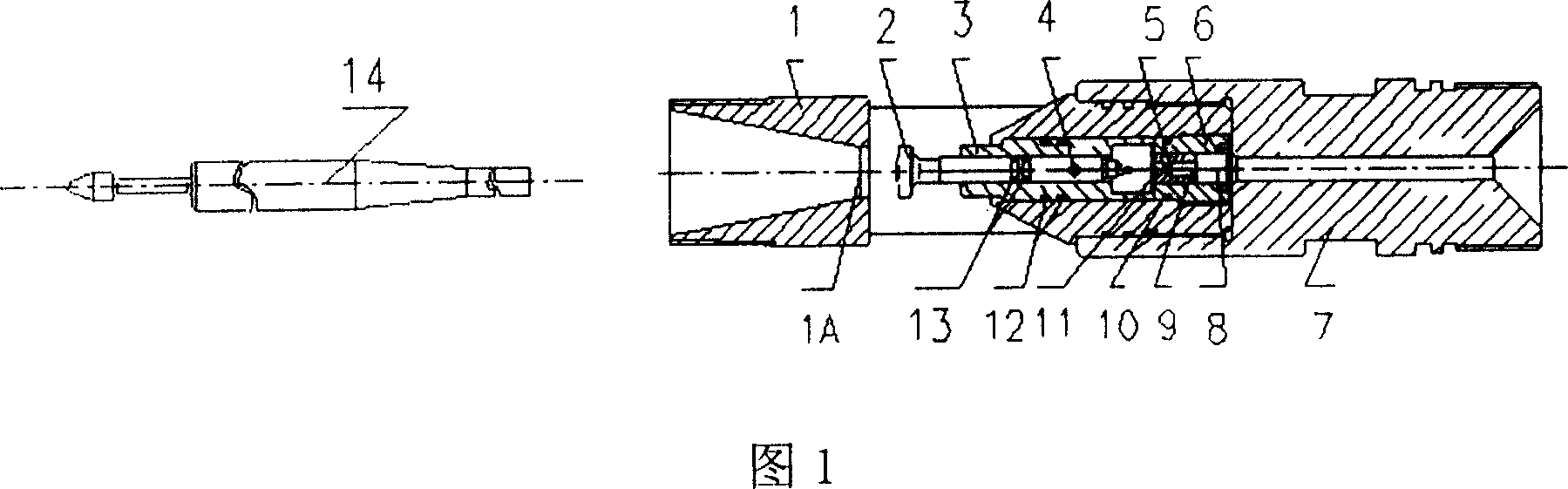

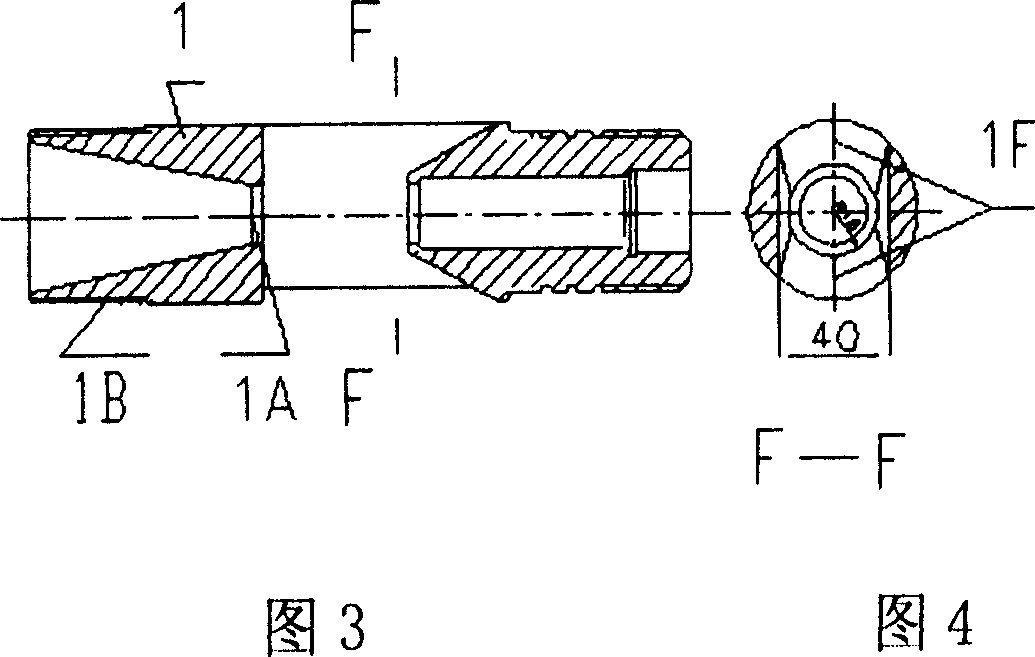

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

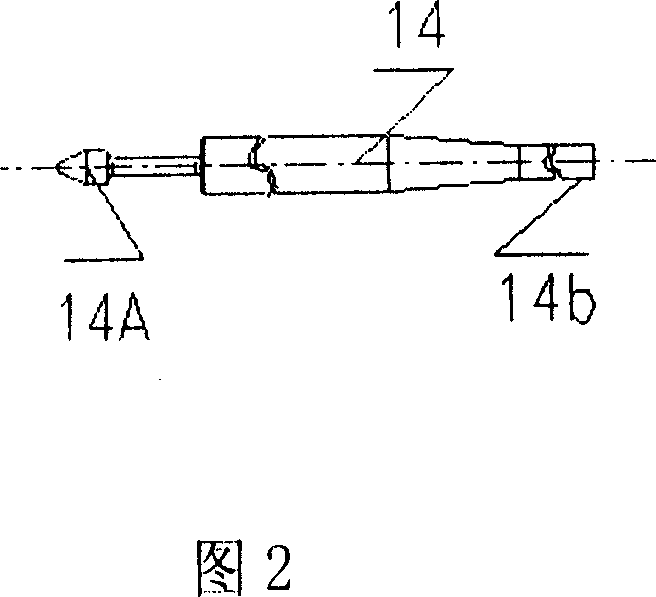

[0018] As shown in Fig. 1, the present invention includes two parts of a mechanical impact firing assembly and a fire upper product assembly. The mechanical impact firing assembly is composed of a body 1, a firing pin 2, a firing pin cover 3, a pressure bearing pin 4, a fire transmission joint 7, a throwing rod 14 and seals 12,13. The firing pin 2 is located in the firing pin sleeve 3 and is connected as a whole by the pressure bearing pin 4. The firing pin sleeve 3 is installed in the inner hole of the body 1, and the fire transmission joint 7 is threadedly connected to the output end of the body 1. The pyrotechnic components are placed In the inner hole of the firing pin cover, its fire cap 5 is adjacent to and aligned with the firing pin. The pressure bearing pin 4 can be made of copper or stainless steel. The fire transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com