Elevator safety circuit detection system

A safety loop, detection system technology, used in elevators, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

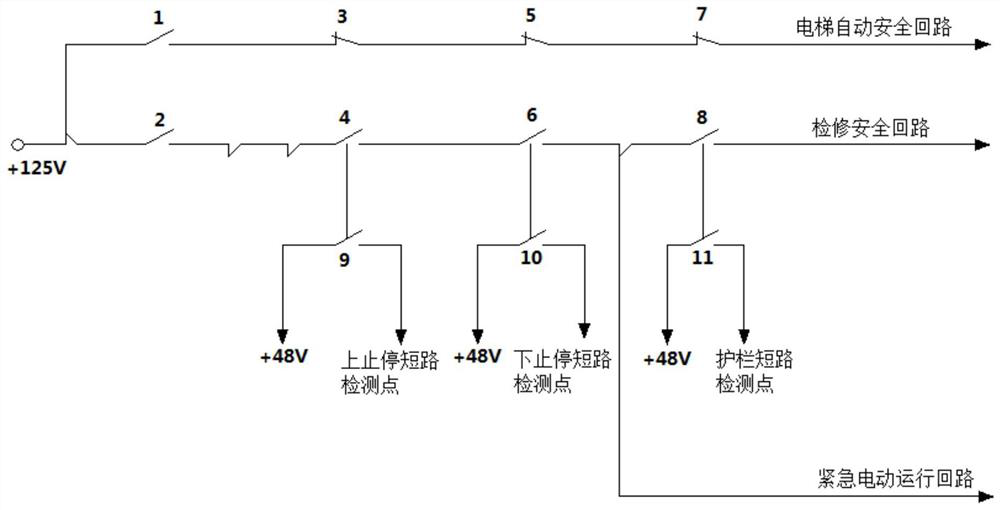

[0065] The elevator safety loop detection system comprises an elevator safety loop, a controller, and an upper stop-stop detection switch 9;

[0066] The elevator safety loop includes an elevator automatic safety loop and an inspection safety loop;

[0067] An upper stop reset switch 3 is connected in series between the working power supply and the input end of the elevator automatic safety circuit;

[0068] An upper stop action switch 4 is connected in series between the working power supply and the input end of the maintenance safety circuit;

[0069] The upper stop action switch 4 is a normally open contact, which is installed next to the upper stop device. The upper stop device has two positions: a reset position and an effective position. When the car rises and the upper stop device is placed in the effective position , the state of upper stop action switch 4 becomes closed;

[0070] The upper stop reset switch 3 is opposite to the switching logic of the upper stop acti...

Embodiment 2

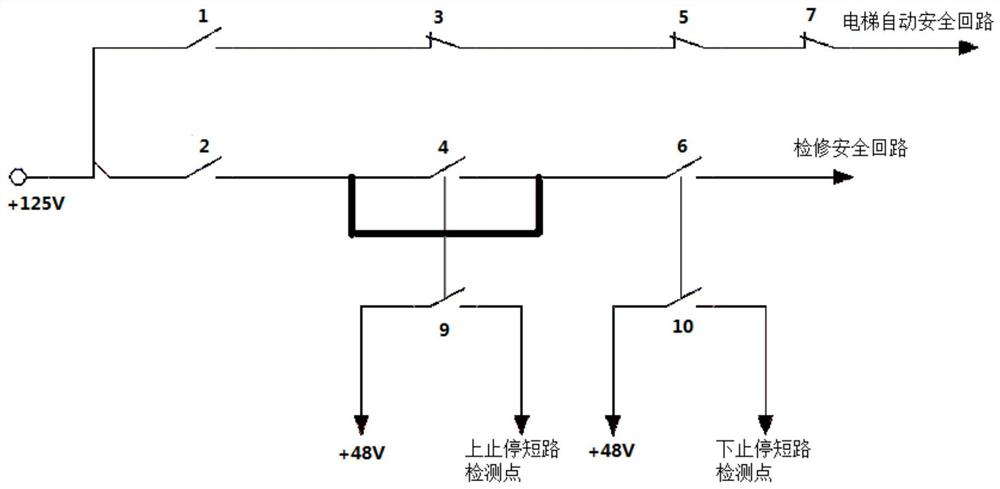

[0082] Based on the elevator safety loop detection system of Embodiment 1, when the input end of the elevator automatic safety loop is at a working high level, and the up-stop short-circuit detection point is at a detection high level, the controller outputs the up-stop reset switch 3 short Receive fault signal.

[0083] Preferably, when the input terminal of the automatic safety circuit of the elevator is at a working high level, and the up-stop short-circuit detection point is at a high level, the controller also controls to prohibit the operation of the automatic safety circuit of the elevator.

[0084] In the wells of buildings with civil construction features on the low roof, the upper stop device gives the maintenance personnel in the well an extra space to avoid danger, and protects the maintenance personnel operating in the well. After the maintenance personnel complete the maintenance operation, the upper stop device needs to be reset, and the elevator can only be all...

Embodiment 3

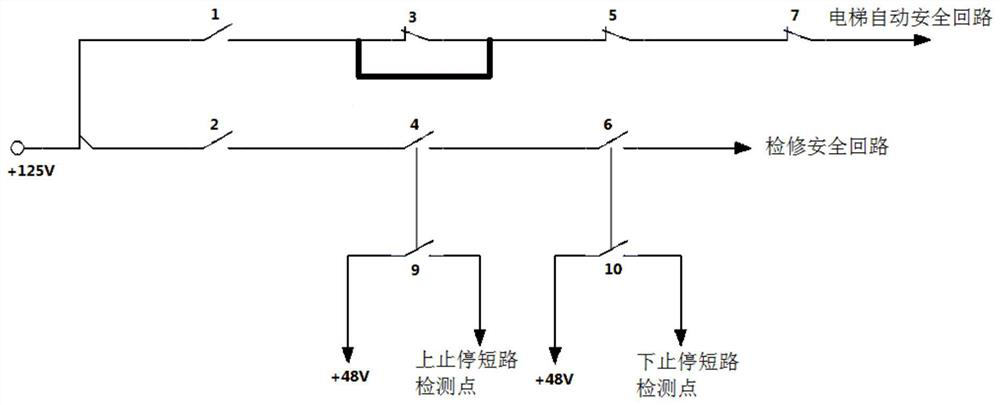

[0087] Based on the elevator safety loop detection system of Embodiment 2, if the processor receives the elevator automatic running state signal, and the elevator automatic safety loop input is at a working high level, and the up-stop short-circuit detection point is at a detection high level, Then output the upper stop detection switch 9 short-circuit fault alarm signal.

[0088] The elevator safety loop detection system of embodiment three, such as Figure 4 As shown, it is possible to carry out self-checking of the short-circuit failure of the upper stop-stop detection switch 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com