Concealed guided groove for fire-proof rolling curtain

A fire shutter and guide groove technology, applied in fire rescue, medical science, dentistry, etc., can solve the problems of large size, large consumption of steel and cement, and space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

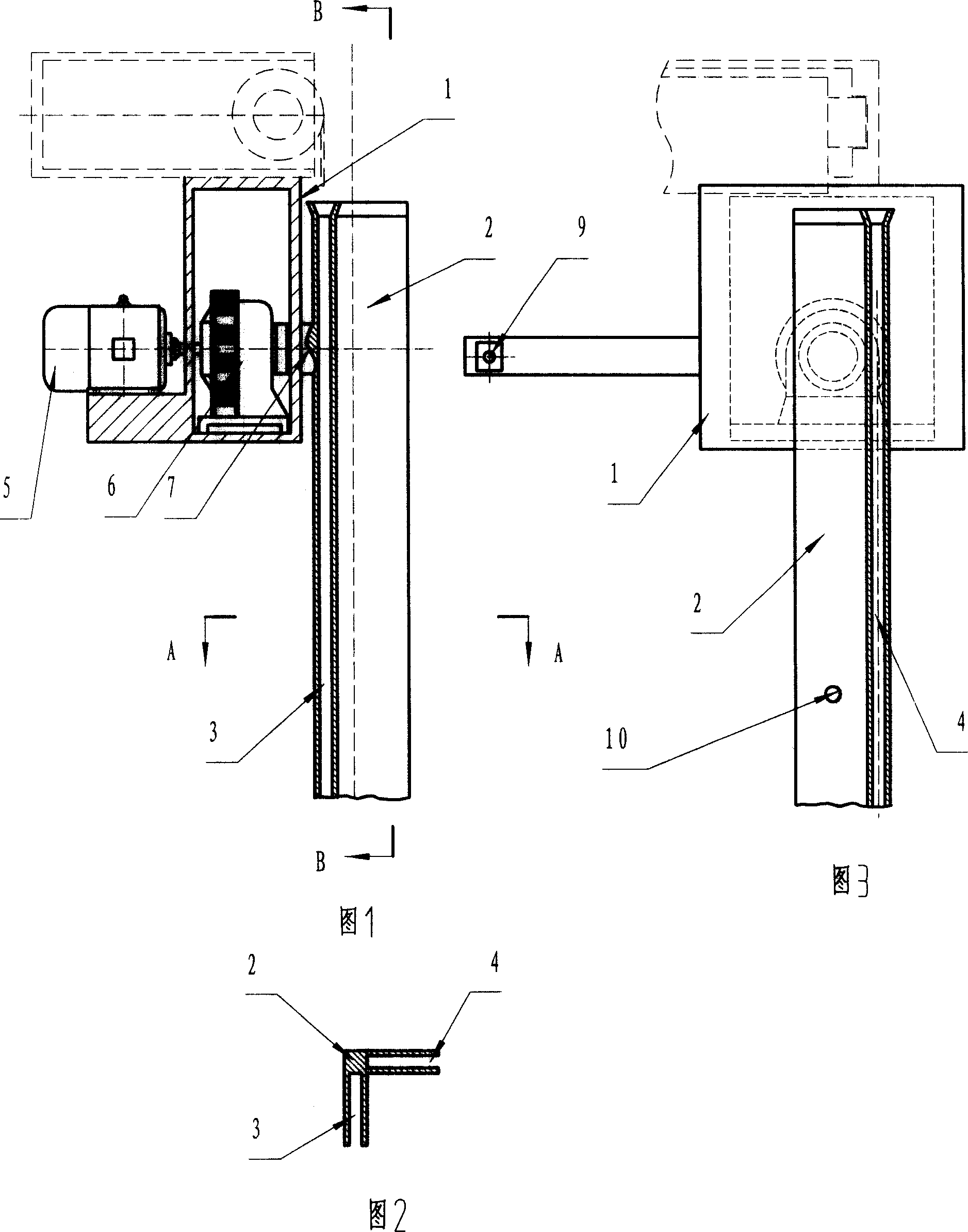

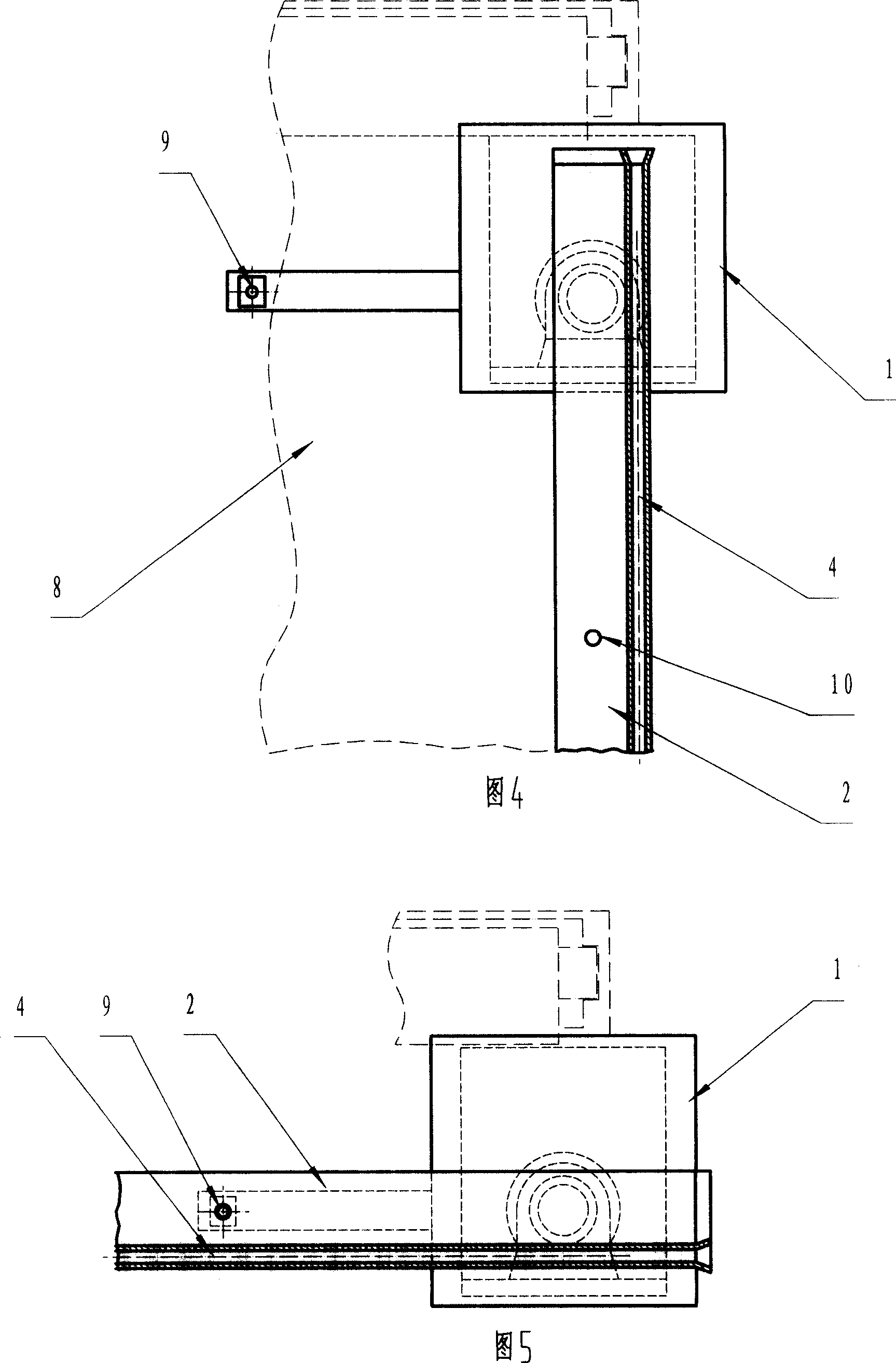

[0028] Embodiment 1: As shown in Figures 1 to 5, the invisible guide groove of the fireproof roller shutter in this embodiment is composed of a frame 1, a movable cylinder 2 and a rotating drive structure, and the cylinder surface of the movable cylinder 2 is provided with a Along the guide grooves 3 and 4 arranged in the direction of the long axis of the movable cylinder, the rotating drive structure is supported by the frame 1, and one end of the movable cylinder 2 is hinged on the frame 1 and connected with the rotating drive structure in transmission.

[0029] In this embodiment, the provided rotary drive structure is composed of a motor 5 and a reduction transmission 6 . Of course, other similar existing transmission mechanisms can also be used to form new embodiments. In addition, special slow-speed motors, such as stepper motors, can also be used to allow them to be directly connected to the movable cylinder 2 for transmission. In this embodiment, the rotating shaft 7 ...

Embodiment 2

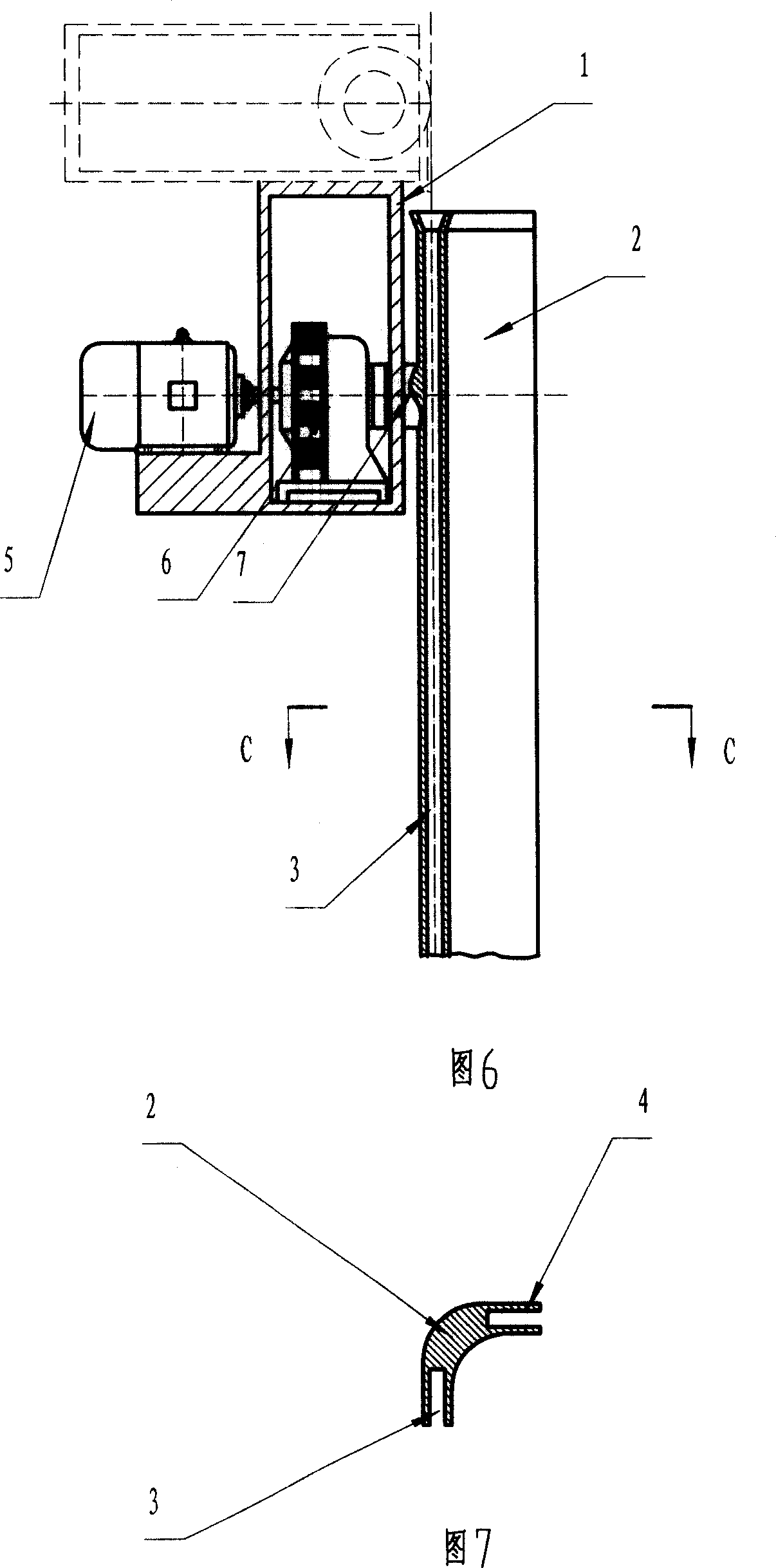

[0034] Embodiment 2: As shown in Figures 6 and 7, the invisible guide groove of the fire shutter in this embodiment is similar to Embodiment 1, the difference is that in this embodiment, the cross-sectional shape of the movable cylinder 2 is slightly changed , but the angle between the opening directions of the guide grooves 3 and 4 is still 90 degrees.

Embodiment 3

[0035] Embodiment 3: As shown in Figures 8 and 9, the invisible guide groove of the fire shutter in this embodiment is similar to Embodiment 1, the difference is that in this embodiment, the cross-sectional shape of the movable cylinder 2 is changed , and the angle between the opening directions of the guide grooves 3 and 4 is greater than 90 degrees, that is, the angle is an obtuse angle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com