High-heat-conducting composite phase-transition energy-storage material and its preparing method

A phase change energy storage material and energy storage material technology, applied in the field of composite phase change energy storage material structure and its preparation, can solve the practical application requirements of unfavorable composite phase change energy storage materials, difficult material combination, and low latent heat of phase change and other problems, to achieve the effect of easy popularization and application, good stability and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

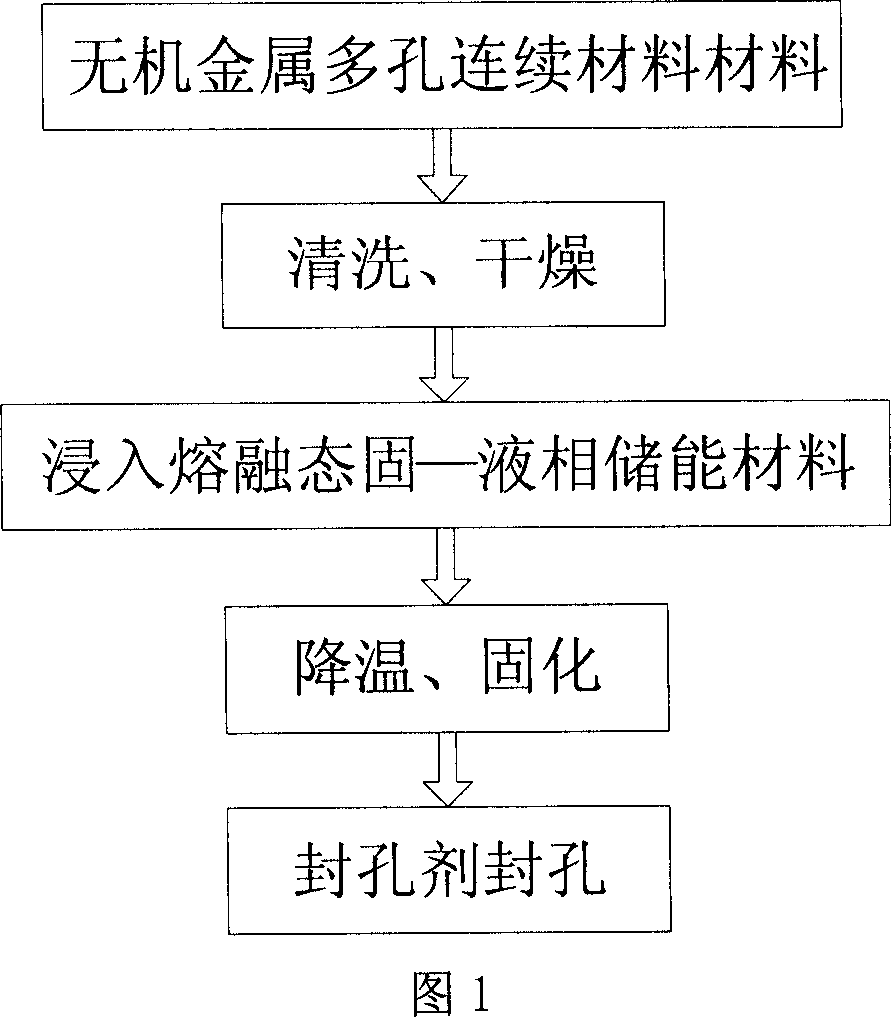

Method used

Image

Examples

specific Embodiment approach 1

[0031] The continuous porous inorganic metal material adopts metal Ni foam, the solid-liquid phase change energy storage material adopts sodium acetate trihydrate, the sealing material adopts epoxy resin, and the composite phase change energy storage material prepared according to the preparation method in the content of the invention absorbs The rate is 74.4%, the energy storage rate can reach 161J / g, the thermal conductivity is higher than 15W / m.K, and the phase transition point is 57°C-59°C.

specific Embodiment approach 2

[0032] The continuous porous inorganic metal material is Ni foam, the solid-liquid phase change energy storage material is sodium phosphate dodecahydrate, the sealing material is epoxy resin, and the composite phase change energy storage material is prepared according to the preparation method in the content of the invention. The adsorption rate is 77.8%, the energy storage rate can reach 179J / g, the thermal conductivity is higher than 15W / m.K, and the phase transition point is 39°C-42°C.

specific Embodiment approach 3

[0033] The continuous porous inorganic metal material is Ni foam, the solid-liquid phase change energy storage material is stearic acid, and the sealing material is epoxy resin. The adsorption rate of the composite phase change energy storage material prepared according to the preparation method in the content of the invention is It is 70.5%, the energy storage rate can reach 110J / g, the thermal conductivity is higher than 15W / m.K, and the phase transition point is 65°C-72°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Phase transition point | aaaaa | aaaaa |

| Phase transition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com