Piston energy exchanger

A transducer and piston technology, applied in the field of acoustic sensors, can solve the problems of small amplitude of piston surface and reduced efficiency, and achieve the effect of increasing radiation capacity and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

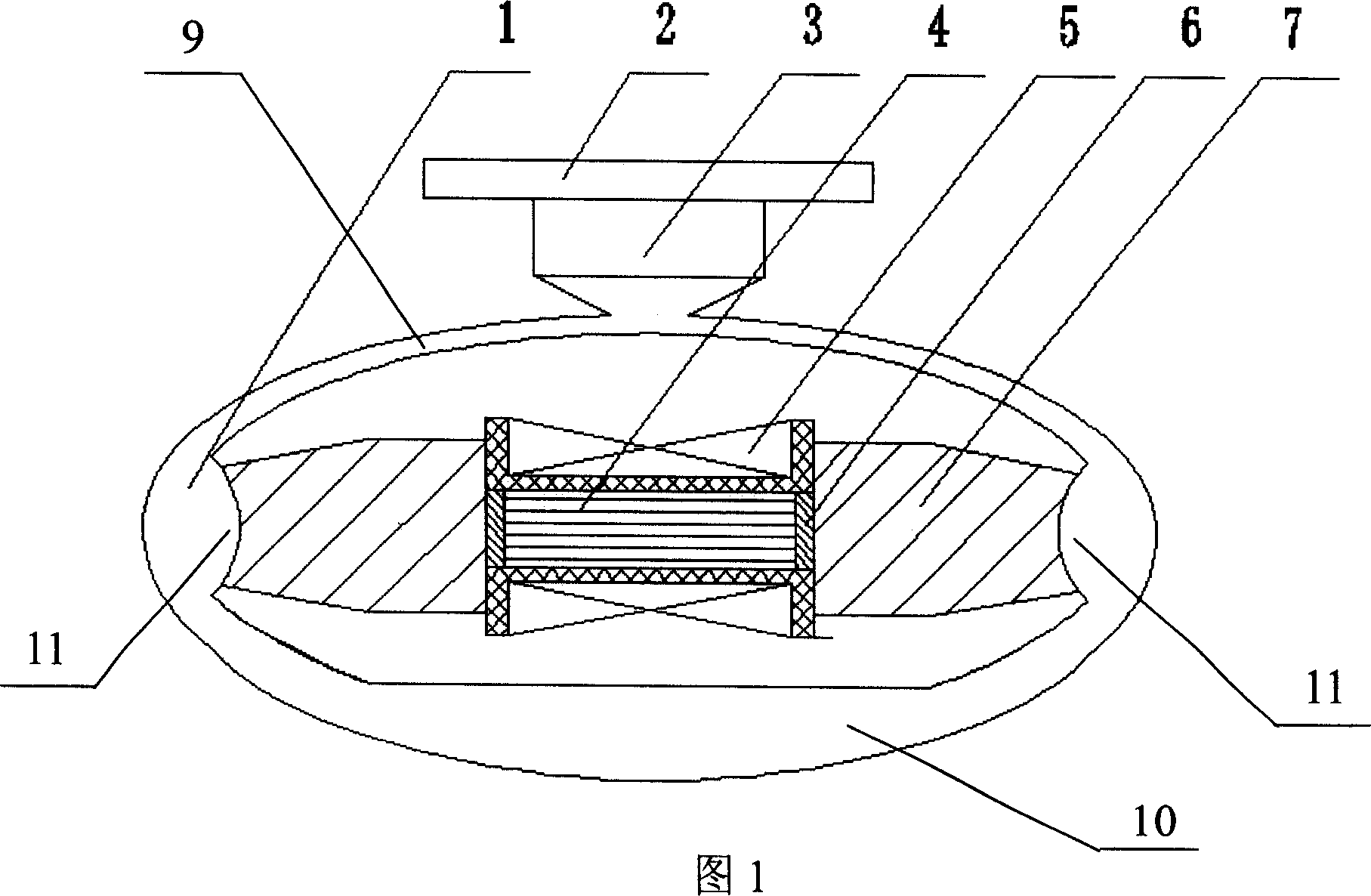

[0020] A transducer shell consisting of an asymmetric flexural casing 1, a transition beam 3 and a circular piston radiation head 2 is made of stainless steel. As shown in Figure 1, the asymmetric flexural shell 1 is a short tube with an elliptical cross-section, and the two ends of the tube are not closed, and the ratio of the tube length to the major axis of the elliptical section should be less than 0.8. The wall thickness of the lower wall 10 of the tube is 5 times that of the upper wall 9 . At the center of the upper wall 9 , the upper wall 9 is rigidly connected to one end of the transition beam 3 , and the other end of the transition beam 3 is rigidly connected to an end surface of the circular piston radiation head 2 . The inner wall of the asymmetric flextensional housing 1 has an inward semicircular protrusion 11 on the left and right sides, and the driving element and the two rigid transition blocks 7 at both ends form the assembly unit of the transducer inner cavit...

Embodiment 2

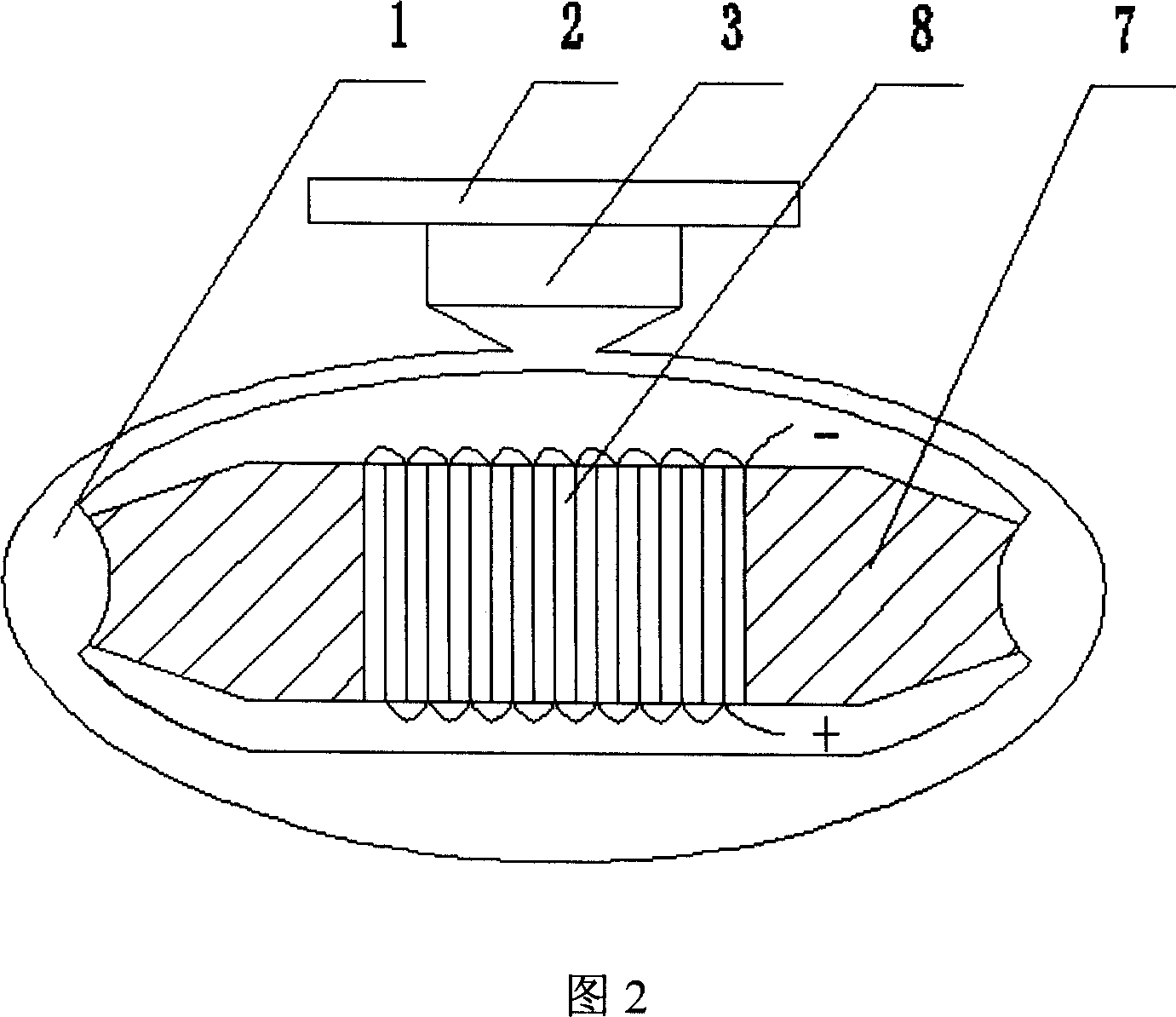

[0024] In this embodiment, a piezoelectric ceramic stack 8 is used as a driving element. The piezoelectric ceramic stack 8 is formed by bonding rectangular piezoelectric ceramic sheets, and the ceramic sheets are connected in parallel in circuit form. The prestressing method of the piezoelectric ceramic stack 8 is the same as that of the first embodiment.

[0025] Other parts of this embodiment are identical to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com