Driveline clunk management system

A transmission system and noise technology, applied in transmission control, engine control, machine/engine, etc., can solve problems such as increasing ignition delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

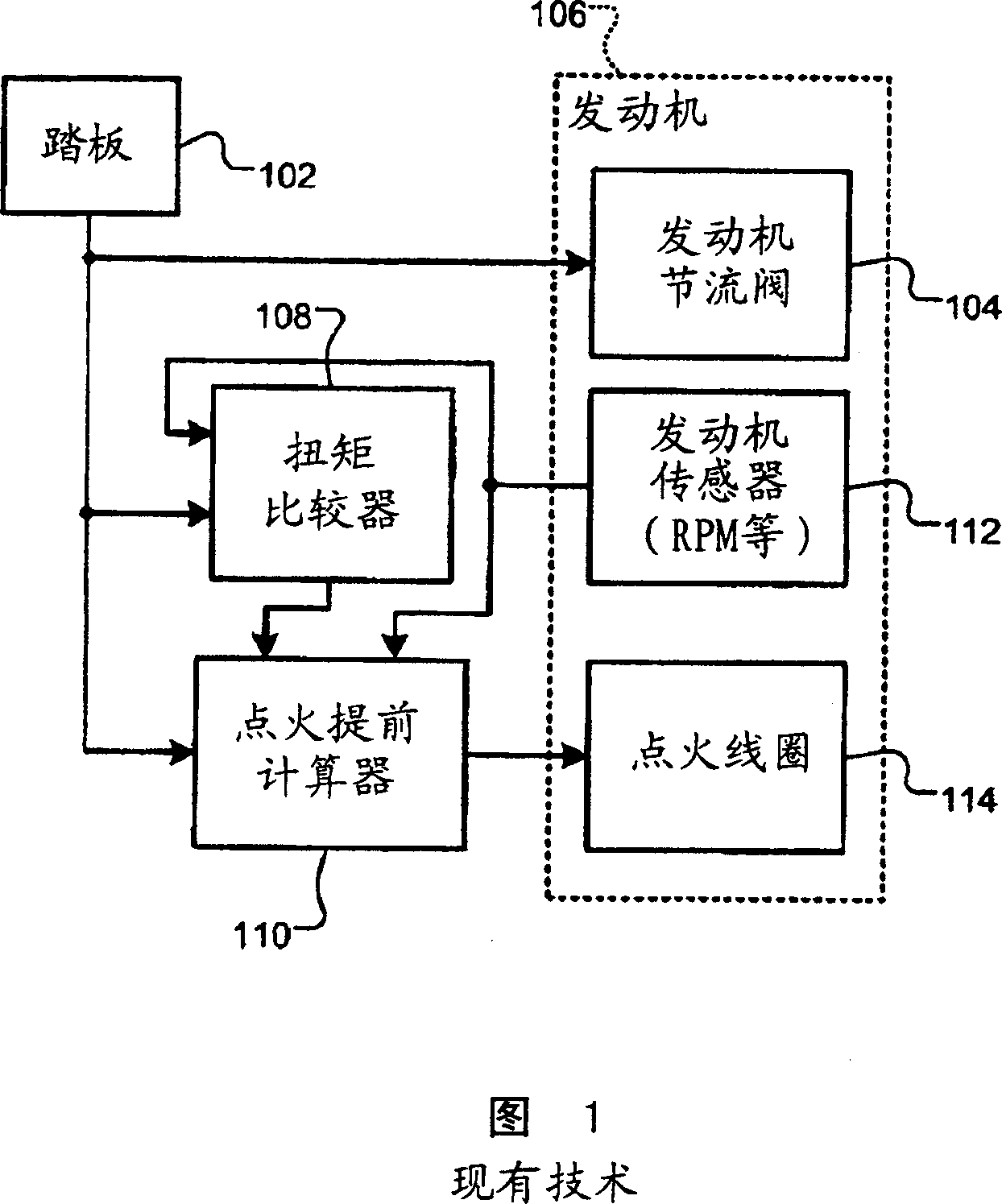

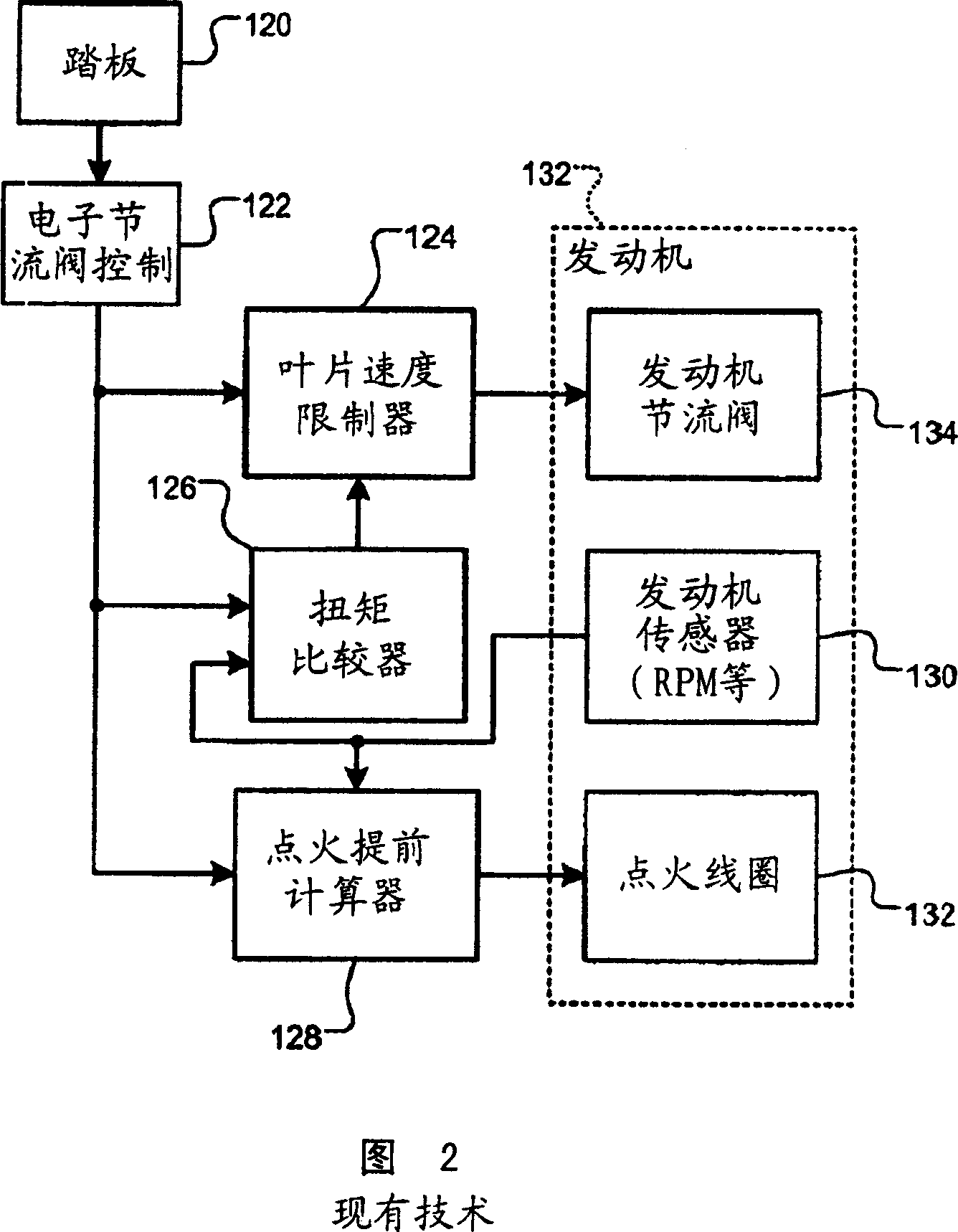

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

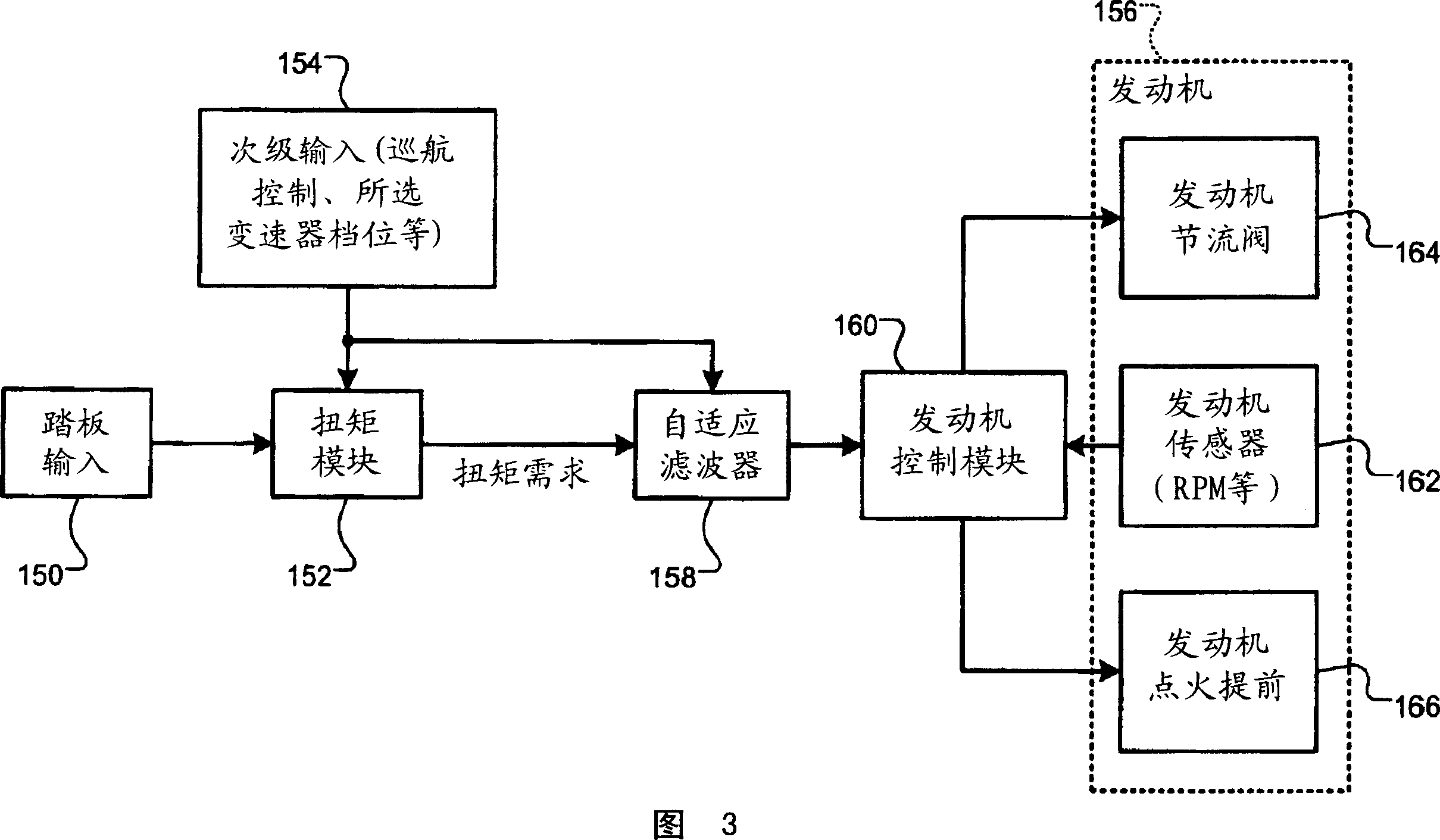

[0016] The following description of the preferred embodiments is only a demonstration of the essence and not a limitation on the application or use of the present invention. For clarity, in the drawings, the same reference numerals indicate similar elements. In this article, the term "module" refers to application-specific integrated circuits (ASICs), electronic circuits, processors (shared, dedicated or grouped) that execute one or more software or firmware programs, memory, and combinational logic circuits. , And / or other appropriate components that provide the described functions.

[0017] Referring now to FIG. 3, shown is a block diagram of an exemplary noise management system in accordance with the principles of the present invention. The driver interacts with the pedal input device 150, which provides pedal information to the torque module 152. The secondary input 154 (eg, cruise control, selected gear, etc.) is provided to the torque module 152. The torque module 152 determ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com