Radiating module and electronic device for collecting dust on radiating fin by vibration

A technology of heat dissipation fins and heat dissipation modules, which is applied in the fields of electrical digital data processing, instruments, digital data processing components, etc., can solve problems such as thermal freeze, affecting the functional operation and computing speed of notebook computers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

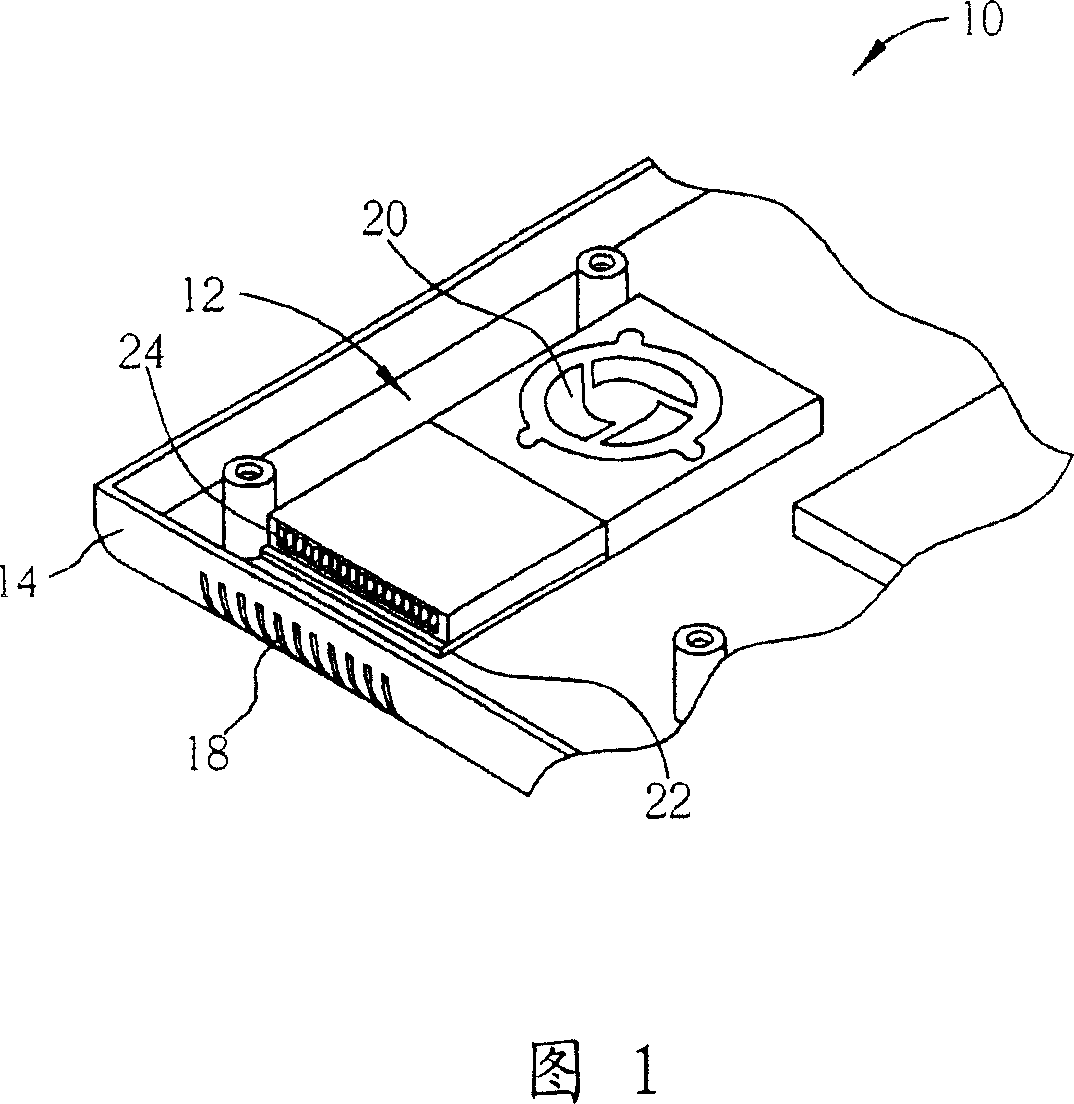

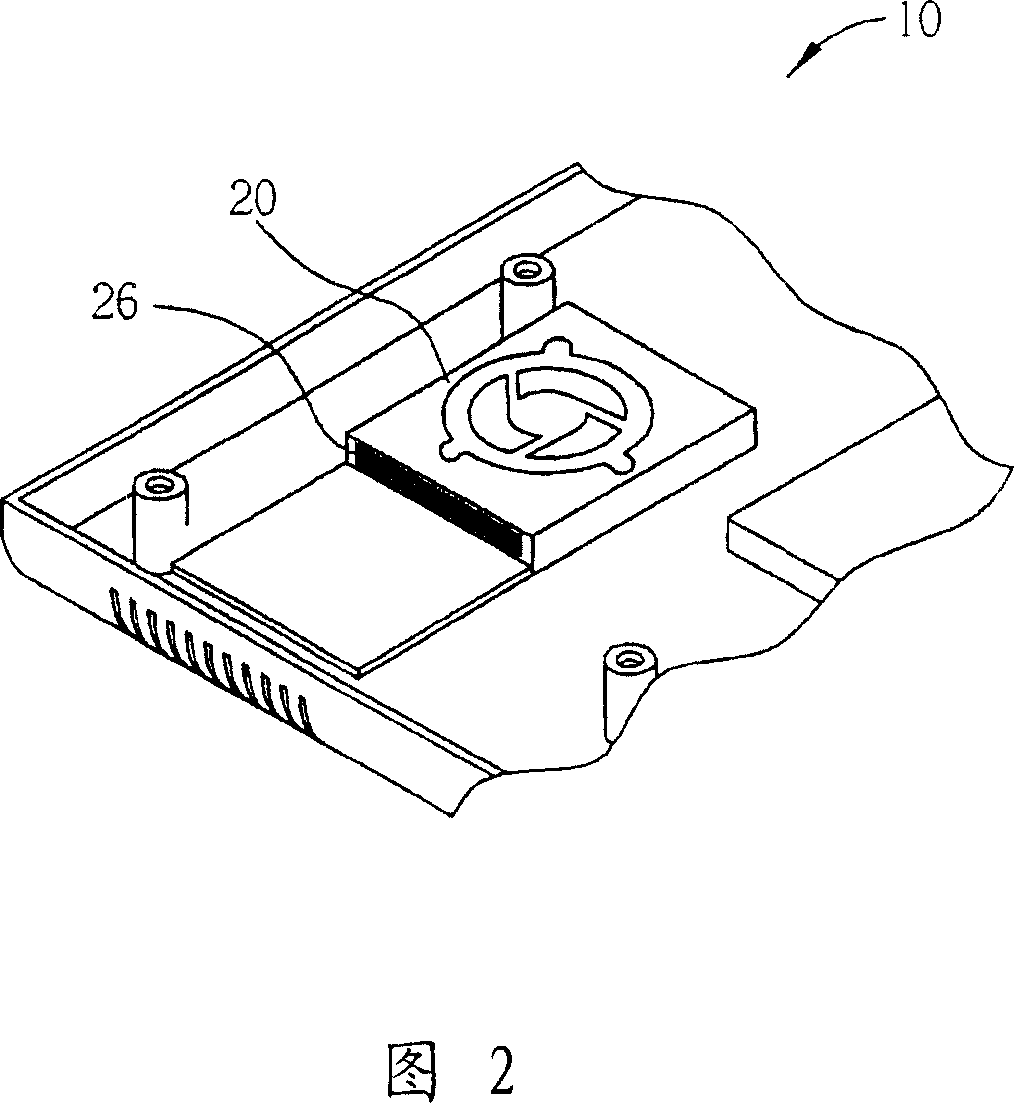

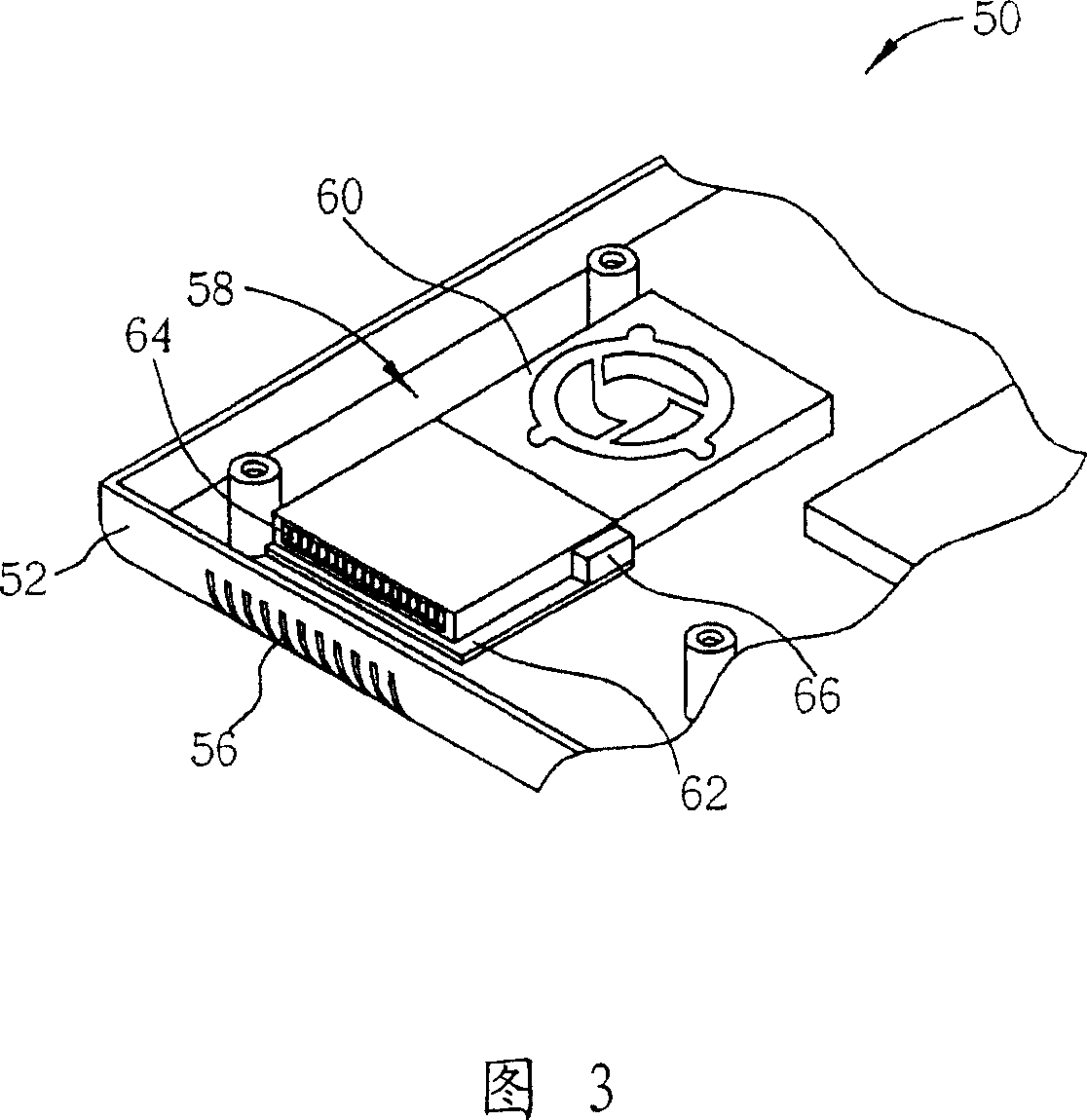

[0013] Please refer to FIG. 3 . FIG. 3 is a schematic view of the internal components of an electronic device 50 of the present invention. The electronic device 50 includes a housing 52 for covering the internal components. An air outlet 56 is provided on the side of the housing 52 . The device 50 further includes a heat dissipation module 58, which includes a fan 60 installed above an air inlet (not shown in the figure), and a base 62 installed between the fan 60 and the air outlet 56 of the housing 52 . The base 62 can be a heat sink, and a plurality of heat dissipation fins 64 are disposed on the base 62 to increase the surface area for heat dissipation. The fan 60 of the cooling module 58 can inhale outside air through the air inlet, and output the inhaled air to a plurality of cooling fins 64 on the base 62, and finally discharge it through the air outlet 56, so as to dissipate the air contained in the internal components of the electronic device 50. The generated heat i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com