Noise reducing plate for secondary cooling tower falling water

A technology of cooling towers and slabs, which is applied in the direction of sound-emitting devices and instruments, can solve the problems of bottom noise reduction, lack of falling water energy dissipation, secondary noise reduction structure, and large secondary noise, and achieve the effect of reducing impact sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in detail below in conjunction with accompanying drawing:

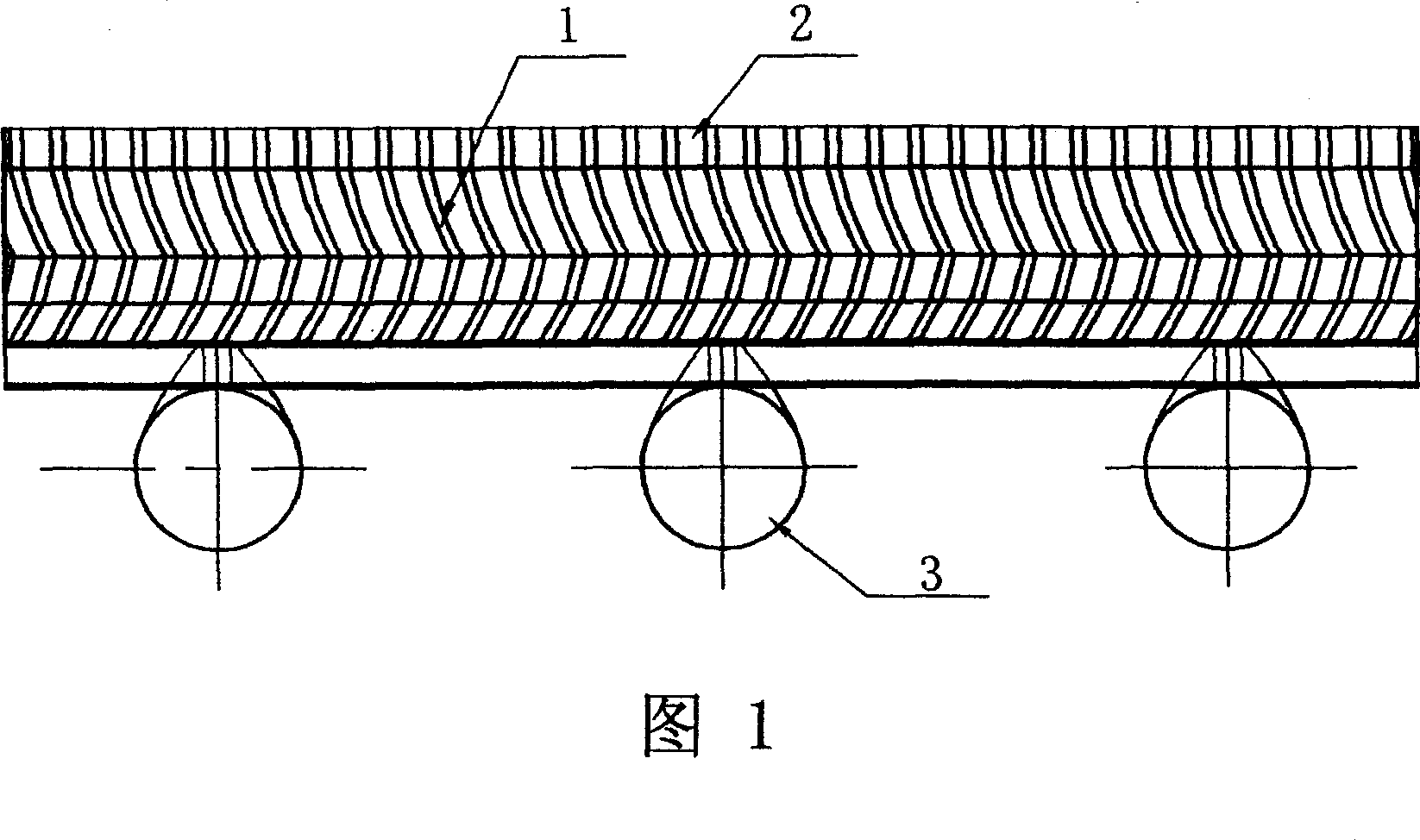

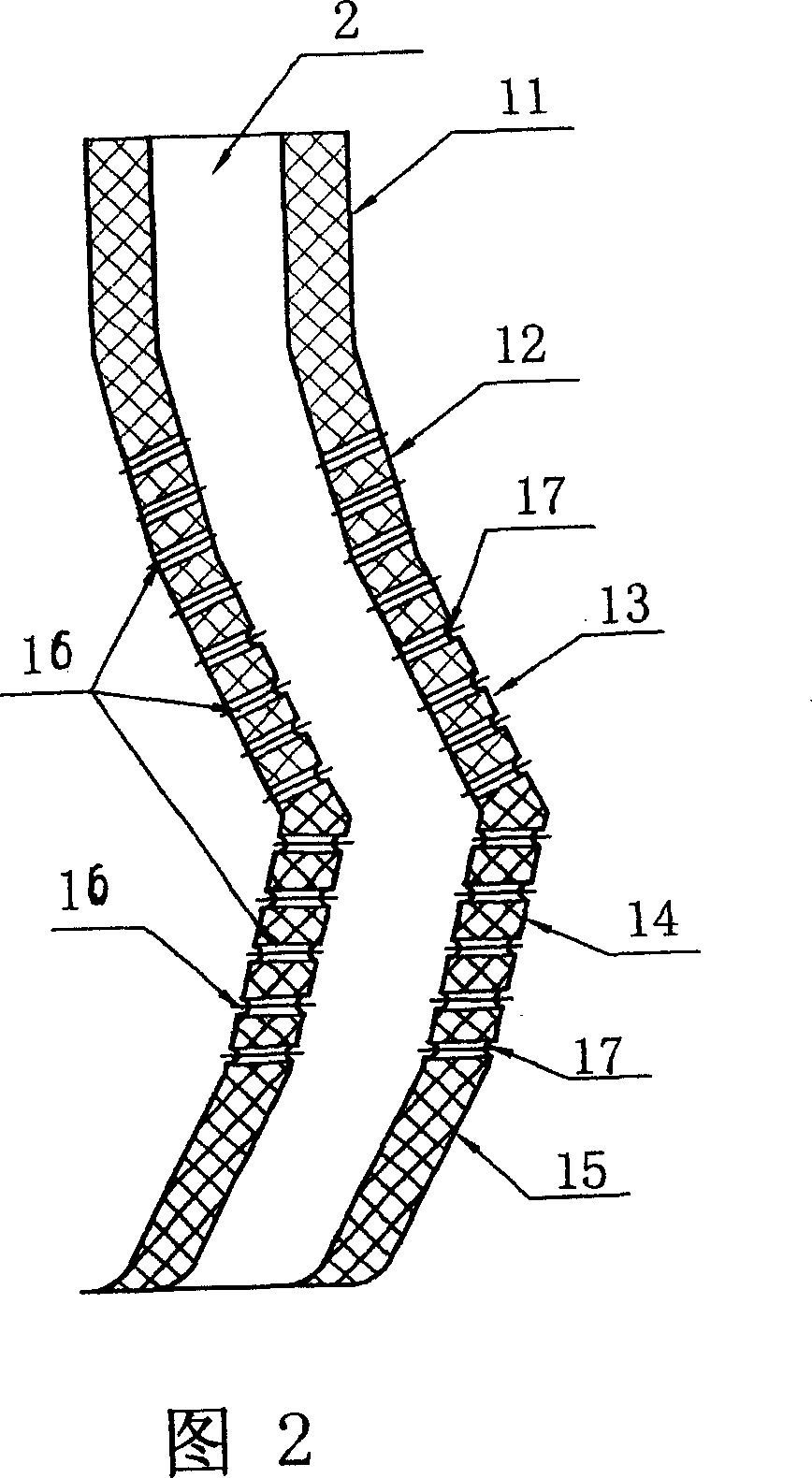

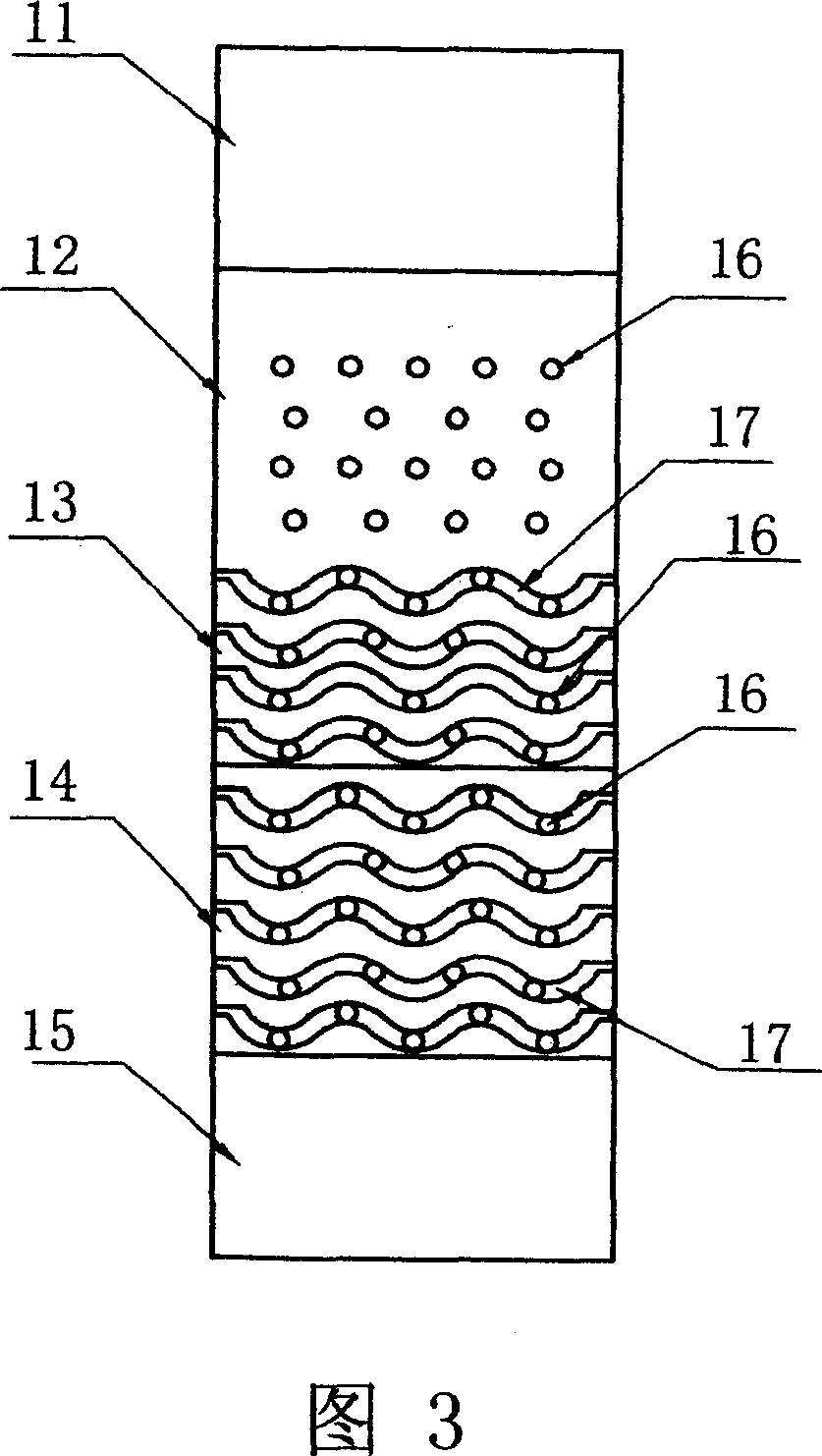

[0016] The second-generation cooling tower falling water plate, as shown in Figures 1 to 4, is a honeycomb layer 1 composed of several formed plastic plates, and a number of sound-absorbing pipes are evenly formed on the honeycomb layer 1. 2. Each muffler pipe 2 is a structure of three sections and five sections. From top to bottom, there are vertical section 11, first-stage inclined section 12, second-stage inclined section 13, reverse return section 14 and deflecting surface section 15. , a number of micropores 16 are uniformly arranged on the first-stage inclined section 12, the second-stage inclined section 13 and the reverse return section 14, and energy dissipation devices are provided on the second-stage inclined section 13 and the reverse return section 14 The corrugated groove 17 of decelerating effect, on the secondary inclined section 13, the corrugated groove 17 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com