Passive speaker vibration board

A vibrating plate and passive technology, applied in the direction of sensors, electrical components, sensor parts, etc., can solve the problems of difficulty in ensuring accuracy, shrinking volume, height cannot be reduced, etc., achieve good audio effects, reduce the volume of speakers, and increase stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

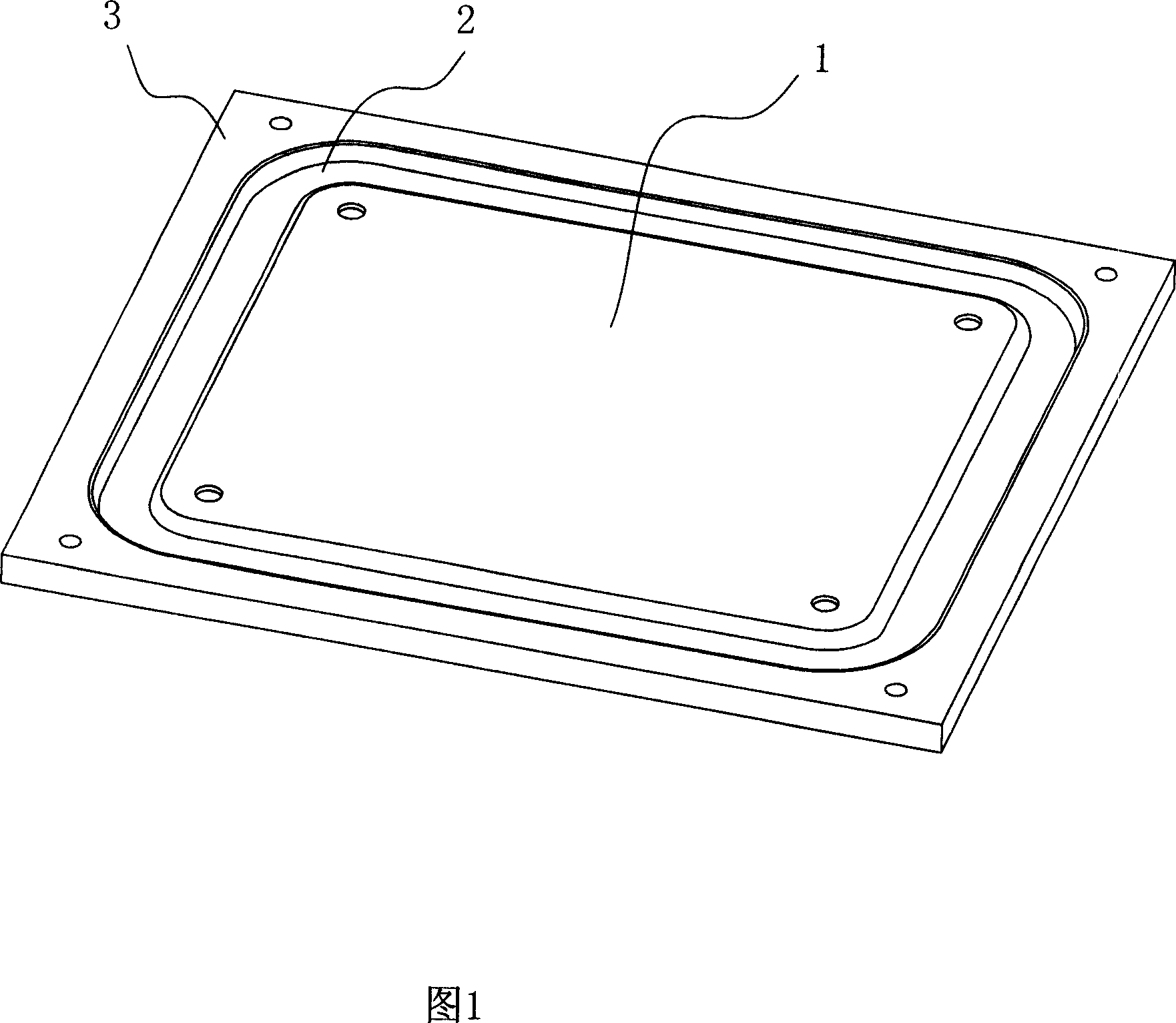

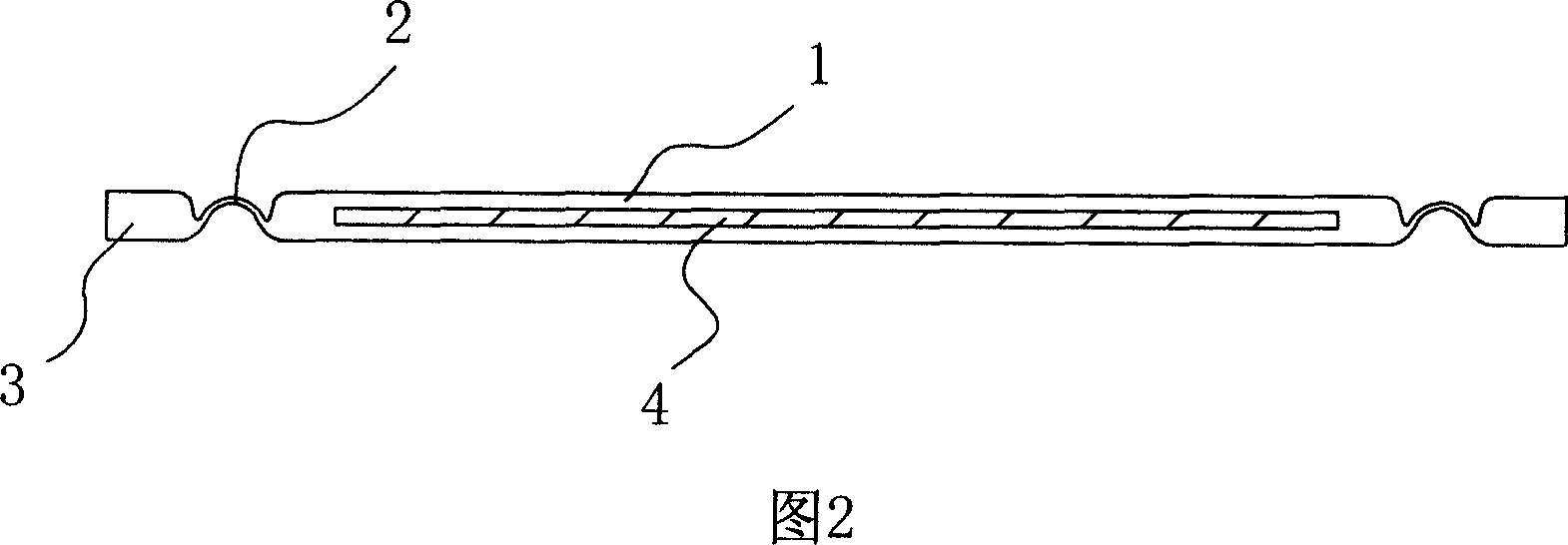

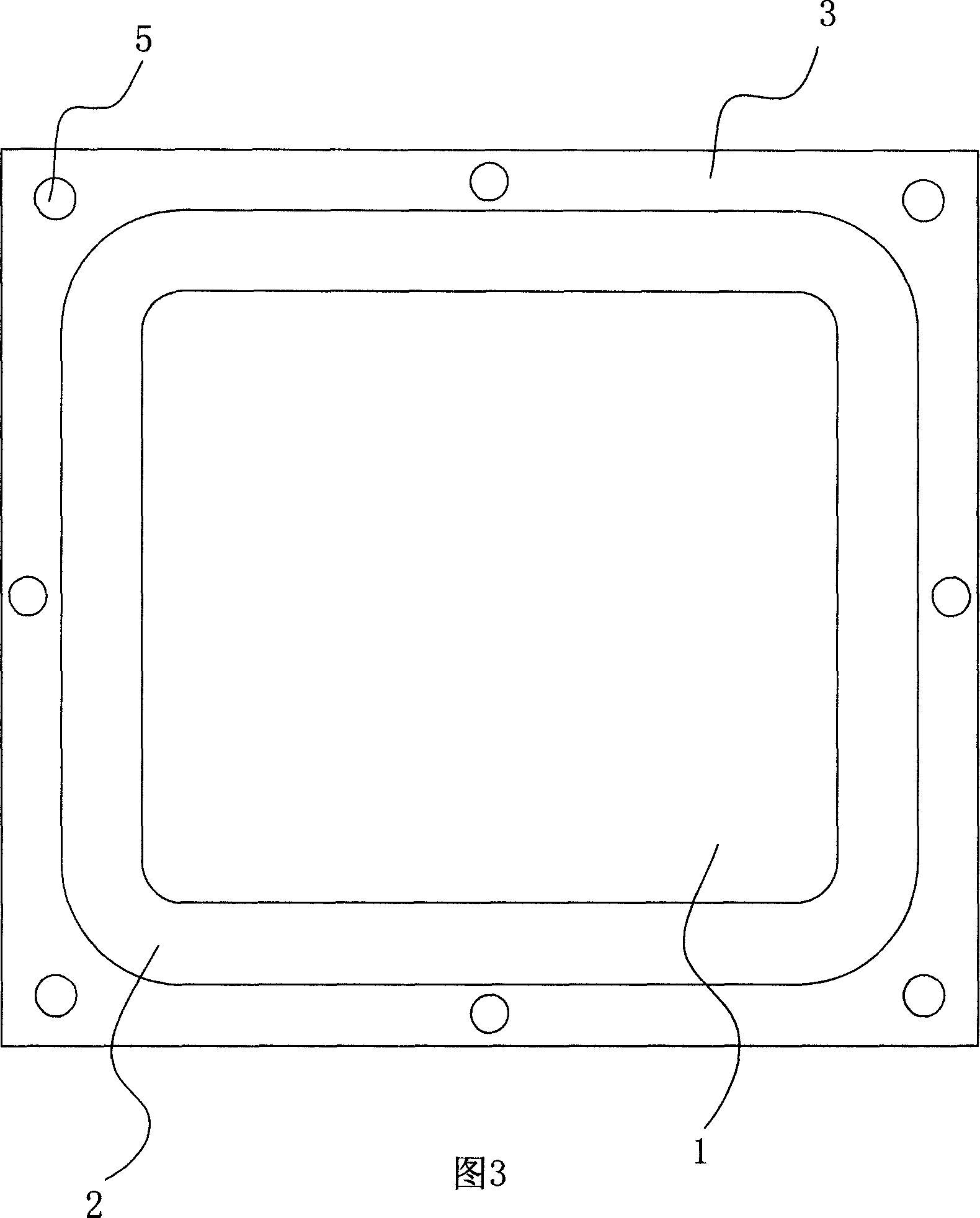

Embodiment 1

[0038] Embodiment 1: As shown in Figures 1-3, the base of the passive speaker vibration plate is thermosetting or thermoplastic elastomer, and its shape is in the shape of a square sheet. The middle part of the base body is the main part 1 of the vibrating plate, which is covered with a central load 4 made of plastic or metal. When in use, the main part 1 of the vibrating plate resonates with the box to produce a low-pitched audio effect. The periphery of the base body is a frame part 3 for combining with the box body, and an assembly hole 5 is provided on this part. The vibrating plate can be assembled on the box body through screws and a pressure strip on the frame, so the assembly is very convenient and can be reused. There is perfect airtightness between its own elastic body covering and the box body. The flexible connection part 2 is a thin rubber edge with a thickness smaller than that of the main body part and the frame part, and its surface is curved, connected between...

Embodiment 2

[0040] Embodiment 2: As shown in Figure 4, it differs from Embodiment 1 in that the frame part 3 is coated with iron or rubber or plastic skeleton 6, which is integrally overmolded with the center load body 4 at the same time during production, and its main effect It is to increase the thickness and strength of the frame part 3, which is specifically designed according to the needs of assembling with the box body.

Embodiment 3

[0041] Embodiment 3: As shown in Figure 5, the main difference between it and Embodiment 1 is the thickness difference on the frame part 3. Compared with the frame in Embodiment 1, its thickness is designed to be thinner, so as to adapt to the assembly with the box body need.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com