Ink sucking device of jetting-drawing machine

A technology of an inkjet printer and a traction device, which is applied to printing and other directions, can solve problems such as affecting production efficiency, drying the ink-absorbing tube, and increasing labor intensity of workers, and achieves the effects of reducing labor intensity, simple structure, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

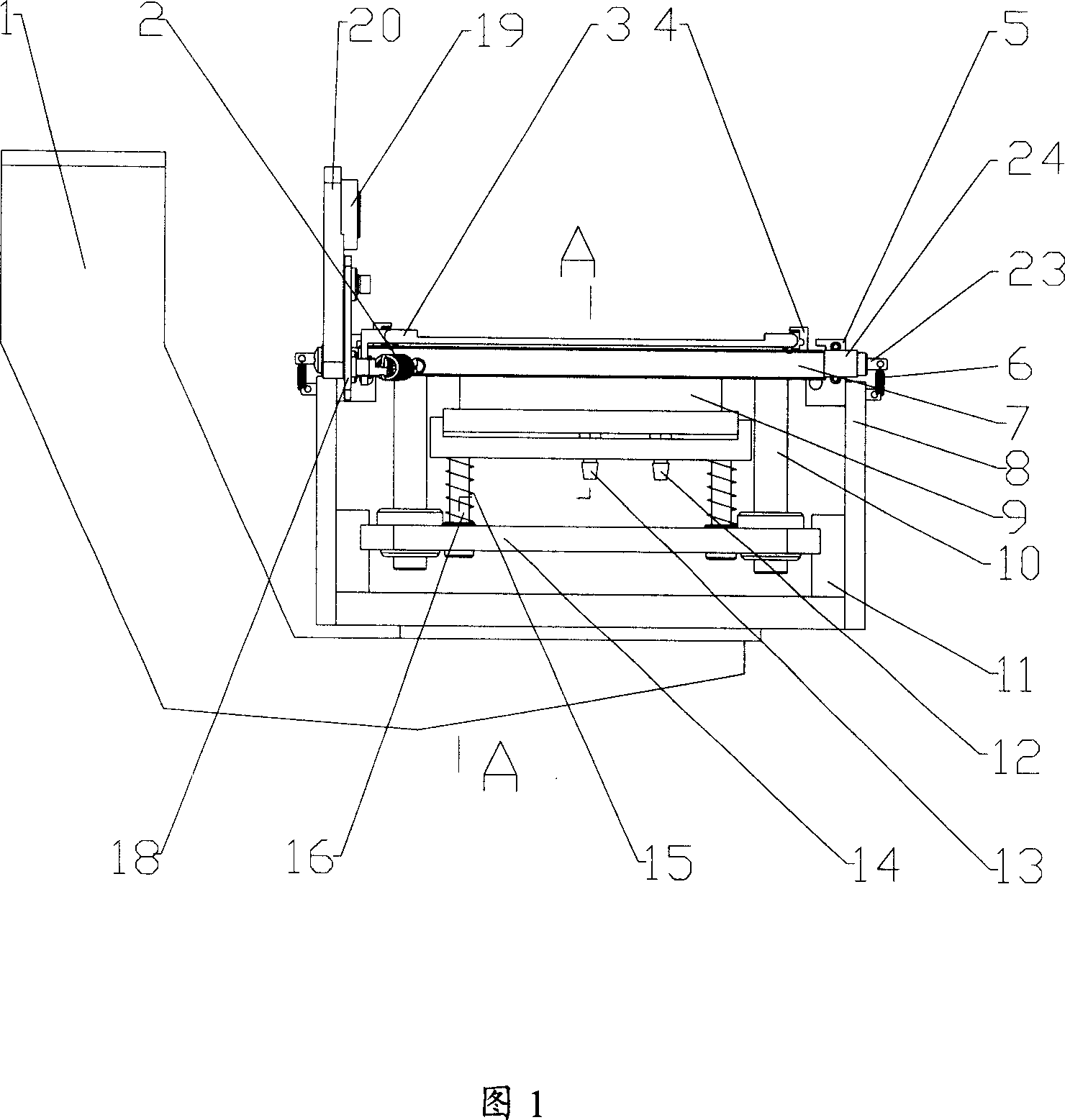

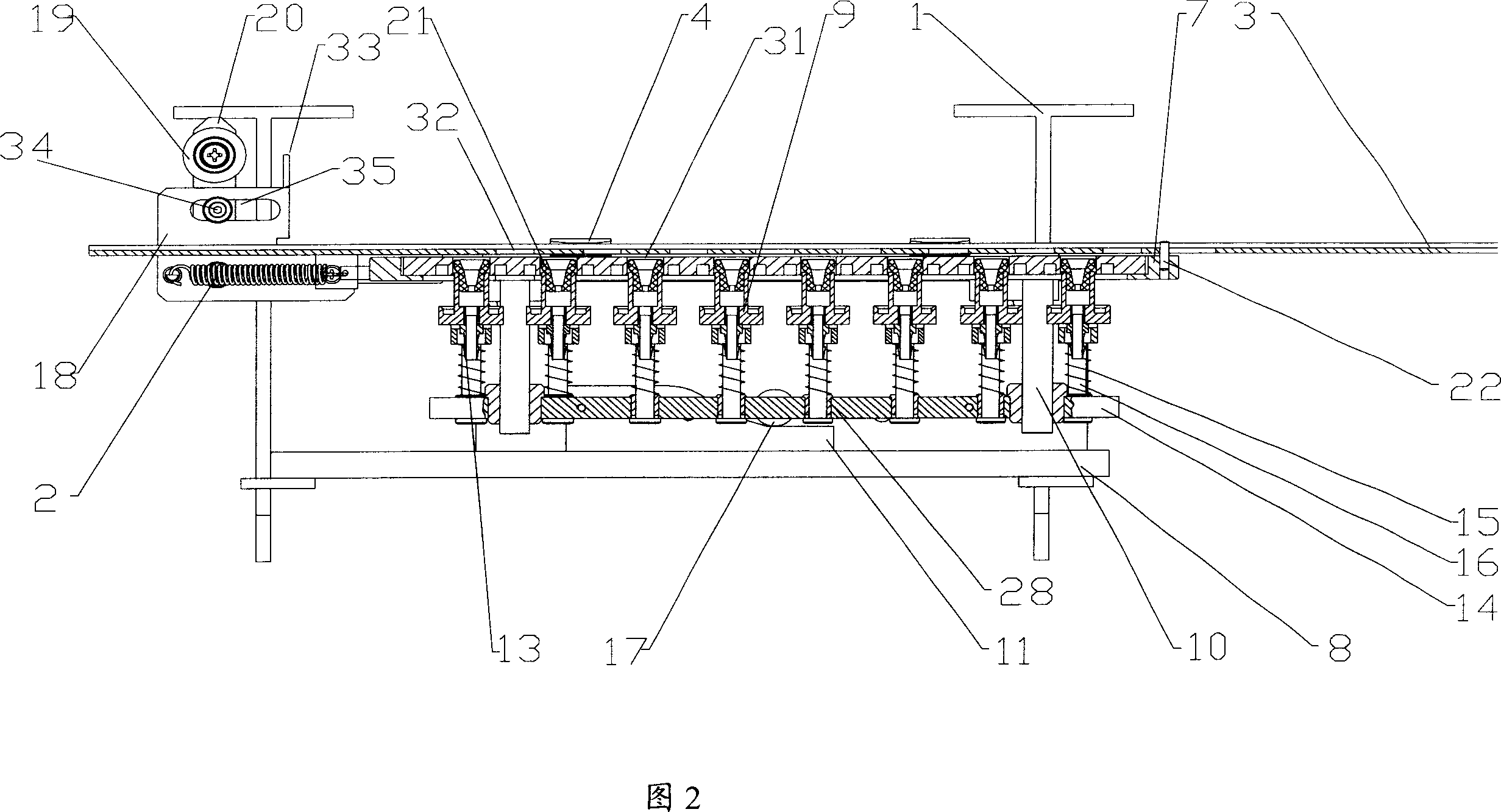

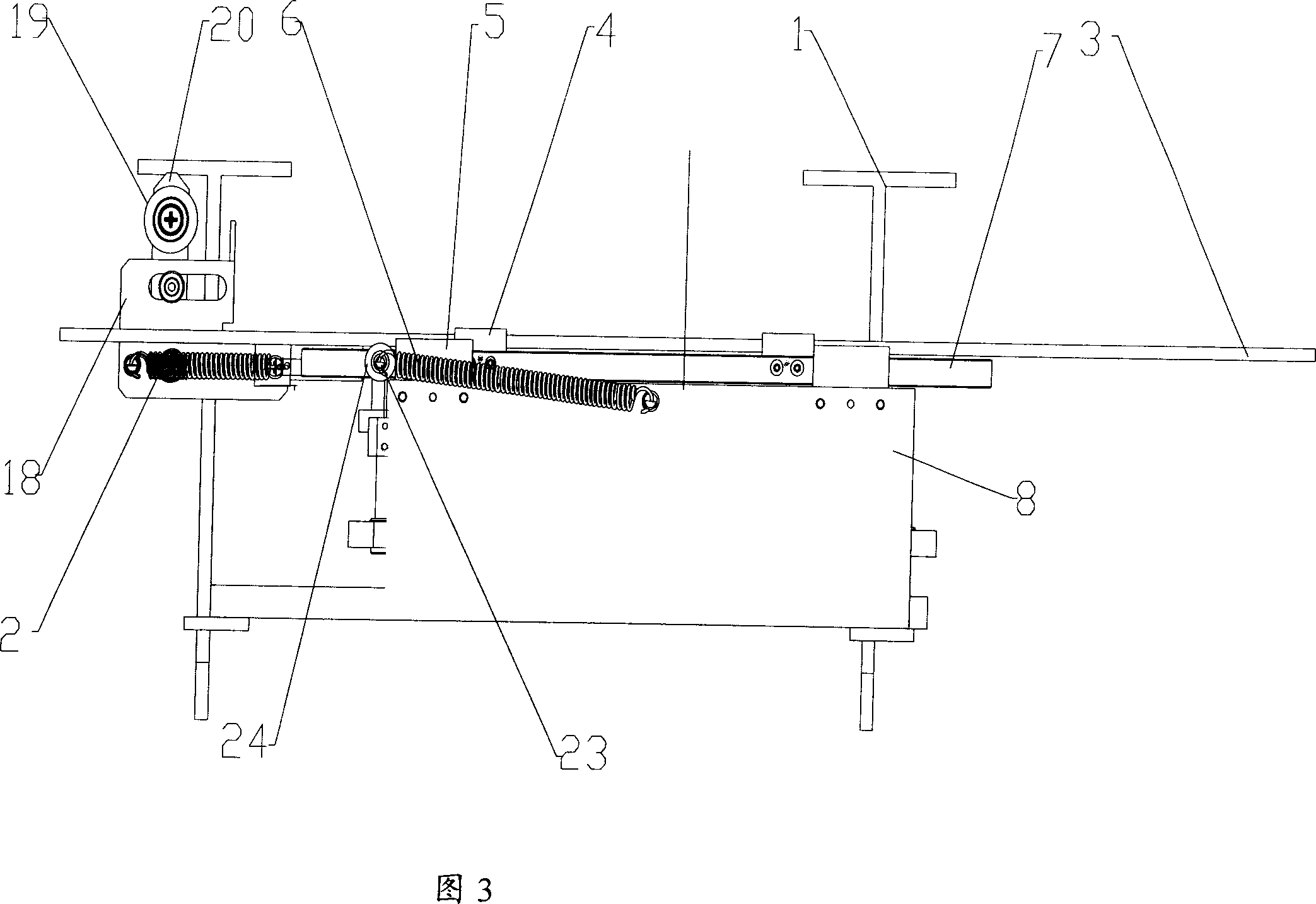

[0023] As shown in FIG. 1 and FIG. 2 , the ink suction device of the inkjet printer provided by the present invention mainly includes a bracket 1 , a base 8 , a tray 7 , a lifting plate 14 and a suction bar seat 9 . The base 8 of the present invention is fixed on the support 1, wherein, as shown in Figure 4, the support 1 is fixed on the guide rail beam 25, and the upper part of the base 8 is fixed with two rows of pallet ball guide rails 5 parallel to the slide rails of the nozzle trolley 27. A tray 7 is placed on the ball guide rail 5, and the tray 7 is provided with through slots 31 corresponding in quantity and position to the nozzles 26. On the ink hole, one end of the tray 7 protrudes and fixes a passive rod 20 near the position of the end of the support 1. The upper end of the passive rod 20 is provided with a roller two 19, and the middle part of the passive rod 20 is provided with a roller three 34. Wherein, if the inkjet printer has UV lamp, as shown in Figure 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com