Catalytic conversion method of double reactor and its device

A catalytic conversion method and reactor technology, applied in the field of catalytic conversion methods and devices, can solve the problems of complex device, difficult implementation, large investment, etc., and achieve the effects of device simplification, low contact temperature, and gasoline olefin content reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

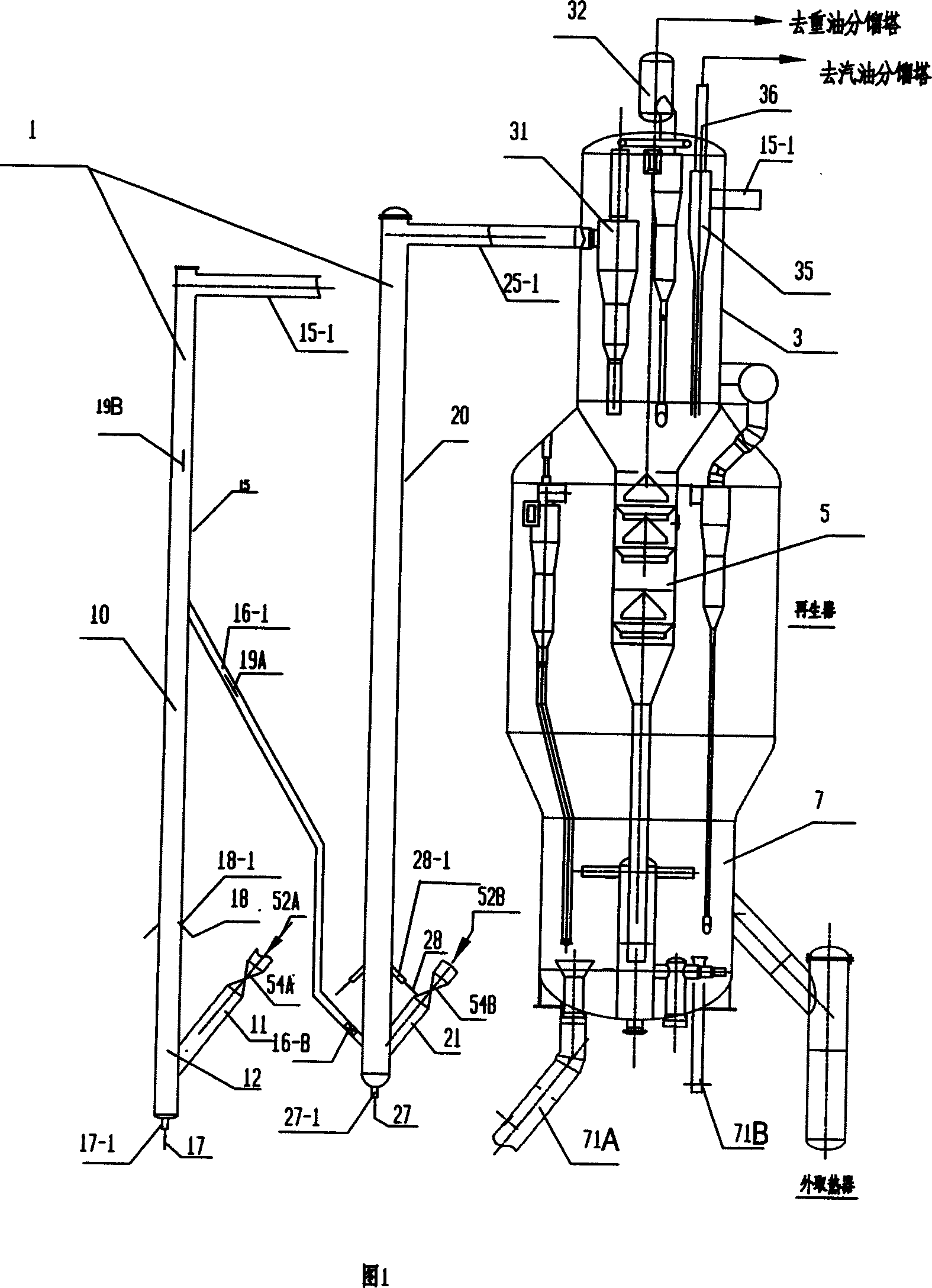

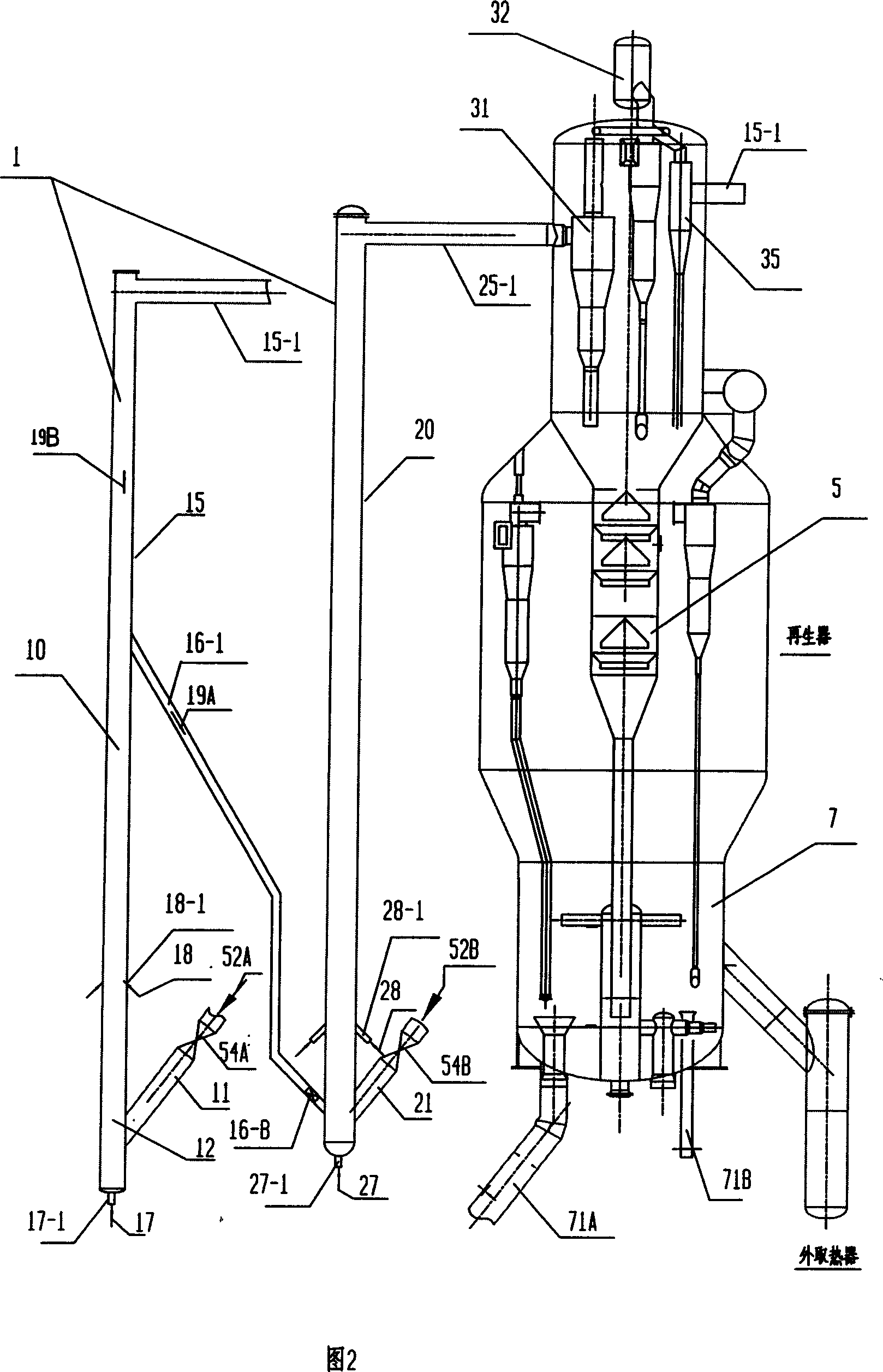

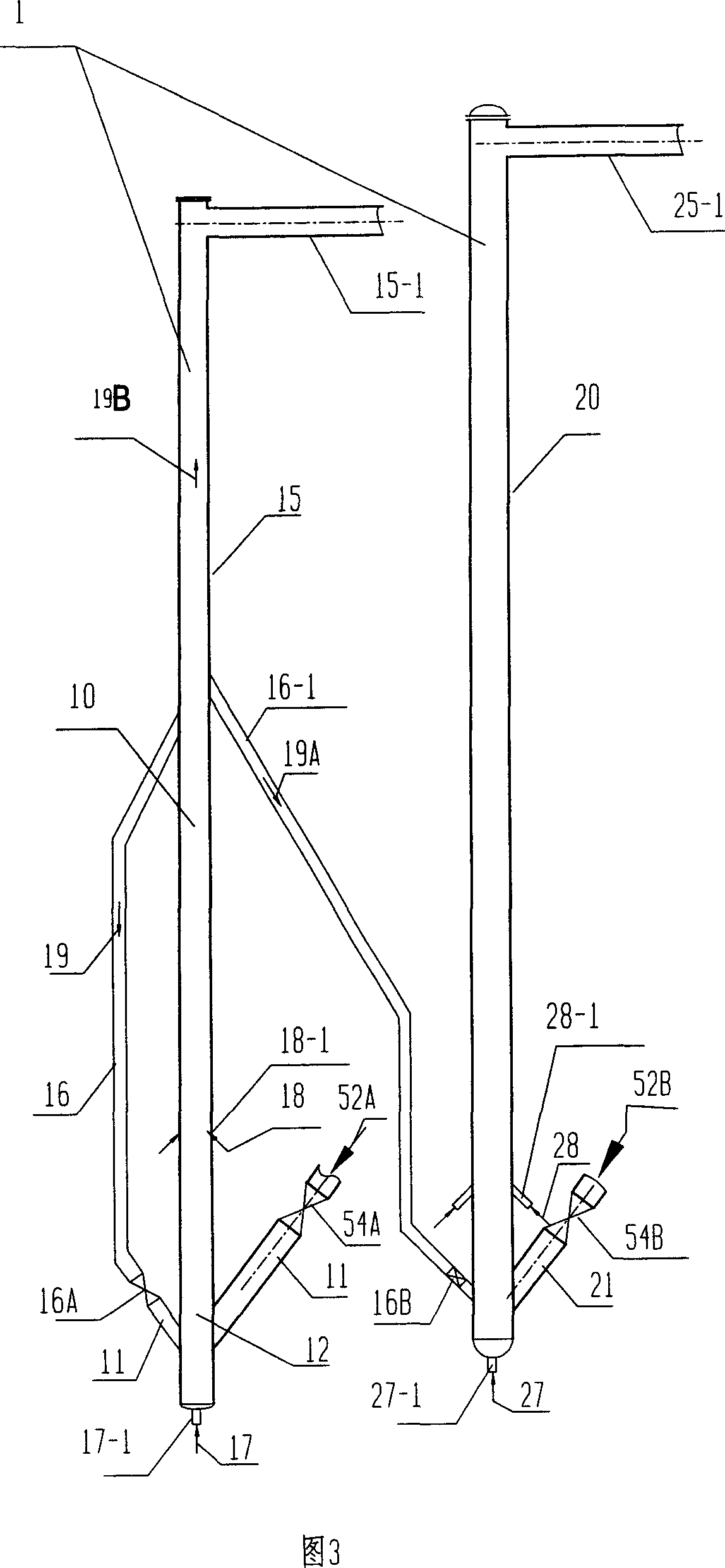

[0032] Example 1. The reaction materials are: pipeline transportation of heavy oil at atmospheric pressure, 100t / h heavy oil, gasoline feedstock is heavy oil reaction self-produced gasoline, with the main purpose of producing low olefin gasoline; heavy oil preheating 220°C, gasoline 40°C; gasoline reaction The reactor uses the patent application number 200510017986.4, and the heavy oil reactor is in the form of a riser; the gasoline and heavy oil reaction products are separated, and enter their respective fractionation towers through their respective oil and gas pipelines for product separation. The heavy oil enters the riser in four ways, and the gasoline enters the reactor in two ways; the reaction temperature of heavy oil is 500°C, the reaction time is 2.5s, the reaction temperature of gasoline is 430°C, and the reaction time is 3s; The temperature of the catalyst before the reaction in the vessel is 600°C; the regeneration temperature is 690°C.

[0033] The device used in ...

Embodiment 2

[0037] Example 2. The reaction materials are: Daqing atmospheric heavy oil, 100t / h heavy oil, gasoline feedstock is heavy oil to react self-produced gasoline; heavy oil is preheated at 220°C, gasoline is at 40°C; the heavy oil reactor is in the form of a riser, and the gasoline reactor is a riser gasification The heavy oil enters the riser in four ways, and the gasoline enters the reactor in two ways; the reaction temperature of heavy oil is 515°C, and the reaction time is 2.5s; the reaction temperature of gasoline is 525°C, and the reaction time is 4s. The residence time in the chemicalization section is 0.5s, and the residence time in the middle fast fluidized bed is 3.5s; the superficial flow velocity of oil and gas in the fluidized bed is 4.0m / s; The catalyst temperature is 620°C; the regeneration temperature is 690°C. The device form used is shown in Fig. 1, wherein the reactor part uses the type shown in Fig. 4.

[0038] Comparative example: The heavy oil reaction part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com