Heat pump system for preparing hot water using after heat and its use method

A heat pump system and water source heat pump technology, applied in the field of heat pumps, can solve problems such as serious pollution, low boiler efficiency, etc., and achieve the effects of stable production capacity, broad market prospects and saving operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

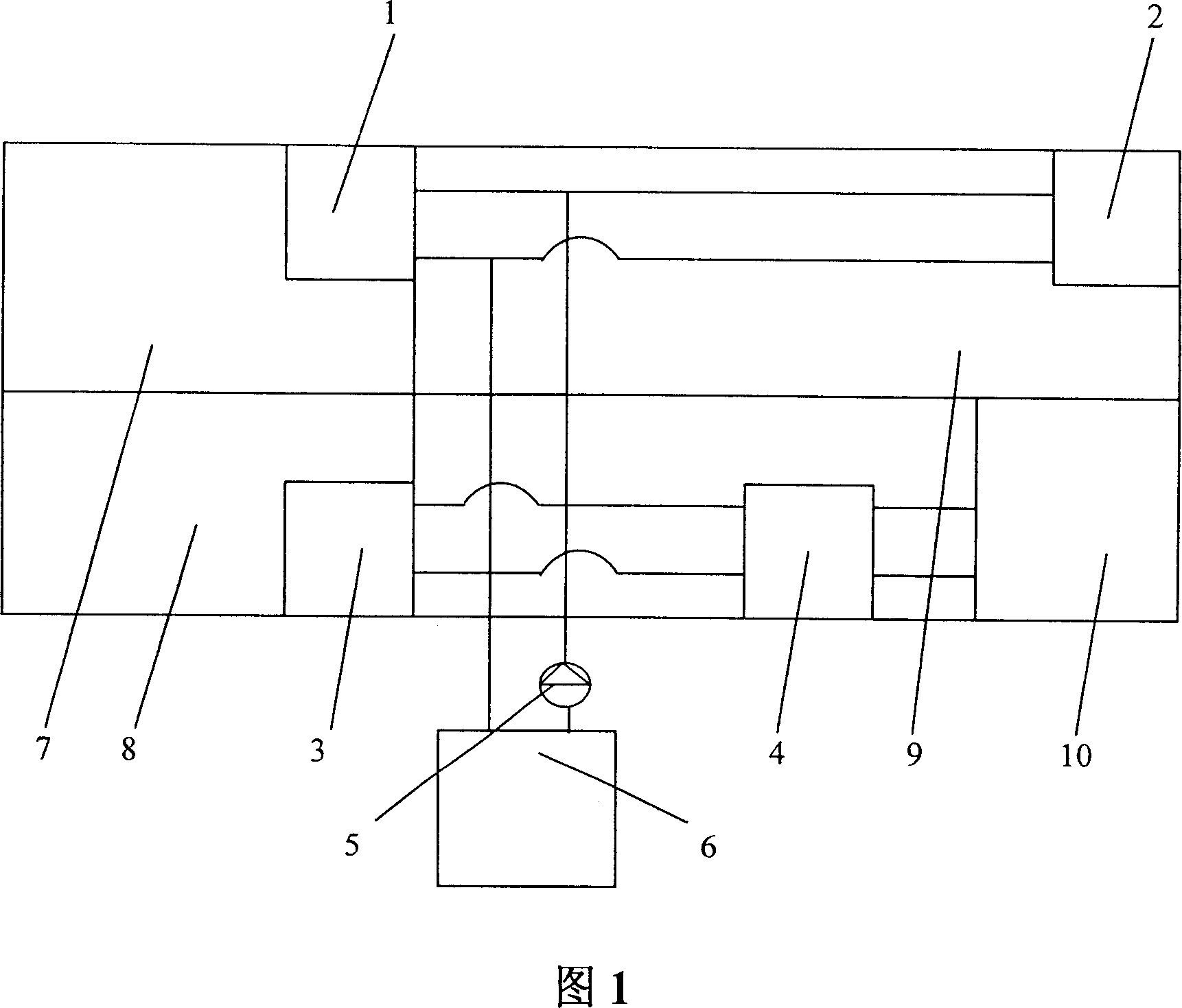

[0021] Embodiment 1: Referring to Fig. 1, the heat pump system utilizing waste heat to prepare hot water in this embodiment, its air source heat pump (1~3) adopts the RB-51K type air source heat pump with a power of 50Kw produced in the United States on the market; the water source heat pump 4. The commercially available RB-81S water source heat pump with a power of 80Kw is used; the water tank 6 is a commercially available ordinary SX-60 heating water tank. The pump 5 adopts a commercially available JYB-40 booster pump with a power of 3Kw. The above air source heat pumps (1-3), water source heat pump 4, pump 5 and water tank 6 are connected according to the above technical scheme and the connection mode shown in Fig. 1 to become the finished product of the present invention. When using the heat pump system that uses waste heat to prepare hot water to produce hot water, the above-mentioned air source heat pumps (1-3) can be respectively arranged in the laundry room 7, the boil...

Embodiment 2

[0023] Embodiment 2: Referring to Fig. 1, the heat pump system utilizing waste heat to prepare hot water in this embodiment, its air source heat pump (1-3) adopts the RB-52 type air source heat pump with a power of 100Kw produced in the United States; the water source heat pump 4 A commercially available RB-82S water source heat pump with a power of 60Kw is used; other components, connection methods and usage methods are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com