Vacuum pump less automatic exhaust device of lithium bromide machine set and its method

A lithium bromide unit, automatic exhaust technology, applied in refrigerators, refrigeration components, adsorption machines, etc., can solve problems such as stuck motors, high prices, and vacuum pump corrosion, so as to improve technical performance, increase operational reliability, and simplify The effect of unit structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

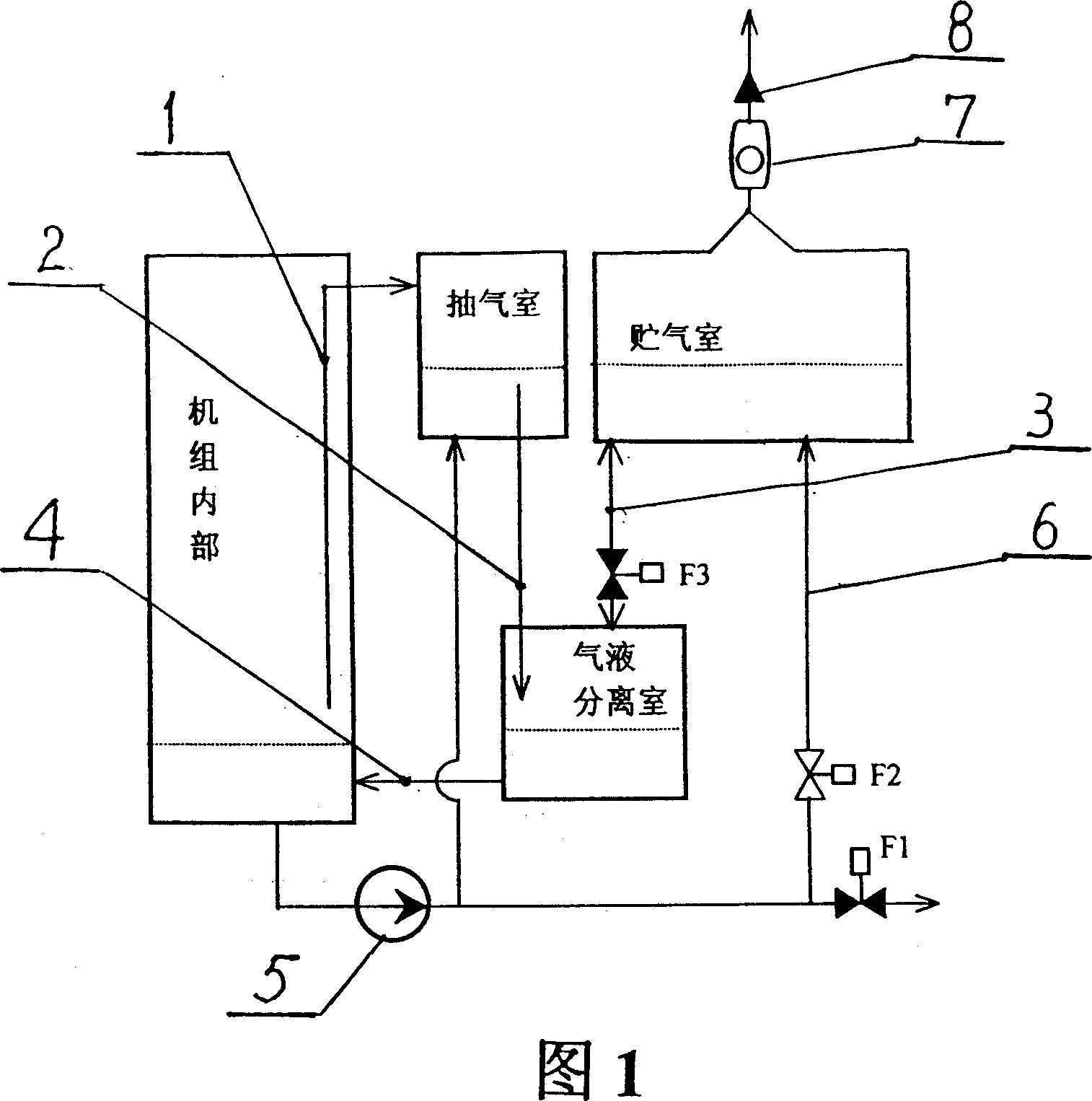

[0010] 1. Referring to Fig. 1, the automatic exhaust device without a vacuum pump of this lithium bromide unit includes an automatic air extraction device, an air extraction chamber, a gas-liquid separation chamber, and an air storage chamber. The inert gas is introduced into the pumping chamber, and the pumping chamber is ejected to the gas-liquid separation chamber through the pumping pipe 2 with a liquid flow. The solution returns to the inside of the unit through the pipeline 4, and when there is a lot of accumulated gas in the gas storage chamber, it needs to be discharged into the atmosphere.

[0011] 2. Referring to Fig. 1, the present invention is provided with valve F1 at the solution pump 5 outlet pipelines of lithium bromide unit, draws the exhaust gas inlet pipe 6 to the air storage chamber between the solution pump 5 and the valve F1, and sets the valve between the exhaust gas inlet pipe 6 F2, a valve F3 is set in the gas guiding and liquid return dual-purpose pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com