Winding type overlapped rotor brushless double feed generator and its control device

A doubly-fed generator and generator technology, which is applied in the control of wind turbines, electromechanical devices, synchronous generators, etc., can solve the problem of high cost of generators and full-power converters, inconvenient reactive power adjustment of generators, and motor problems. The problem of large diameter and size can achieve the effect of facilitating equipment transportation, reducing the weight of the unit and simplifying the structure of the unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

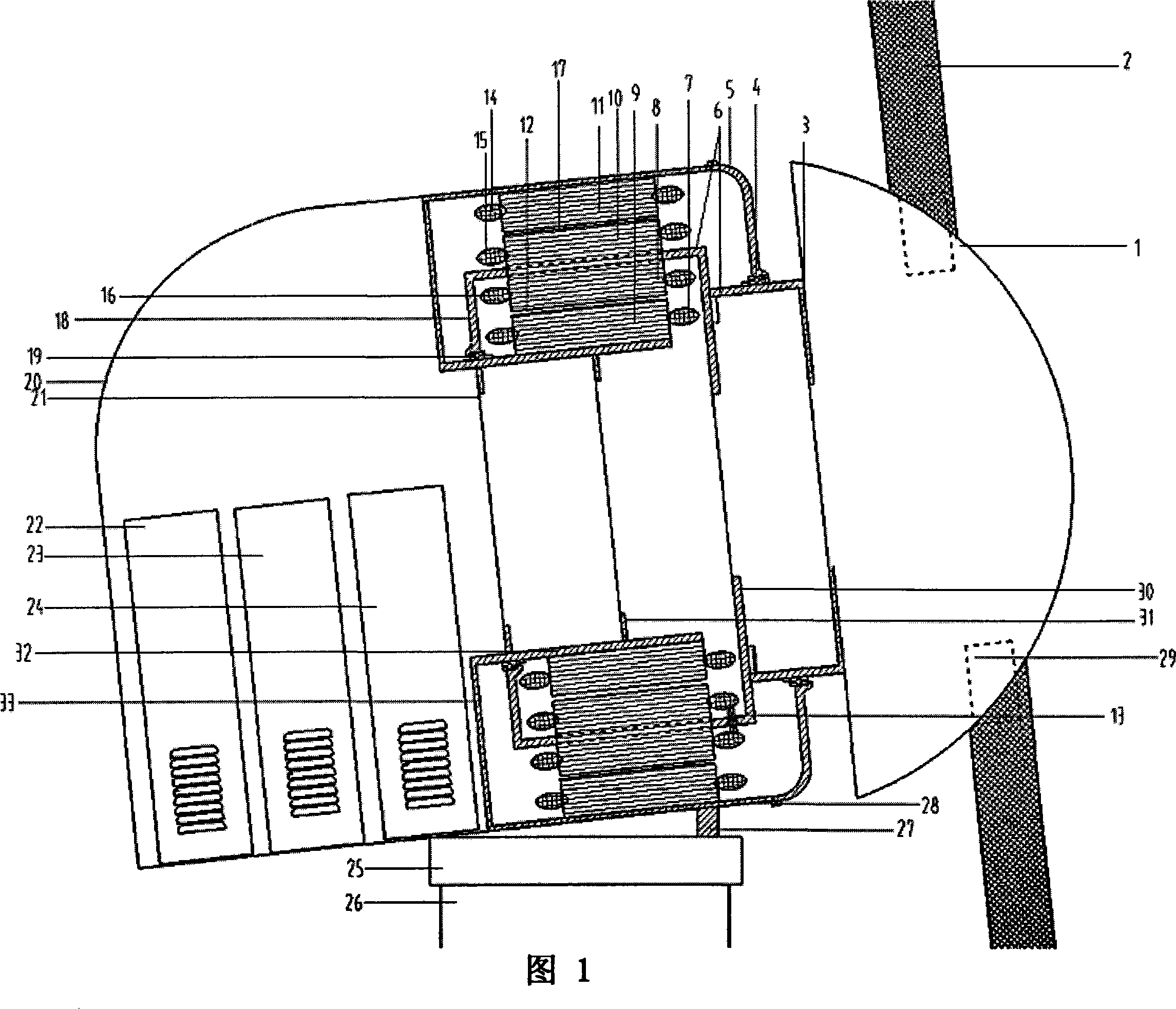

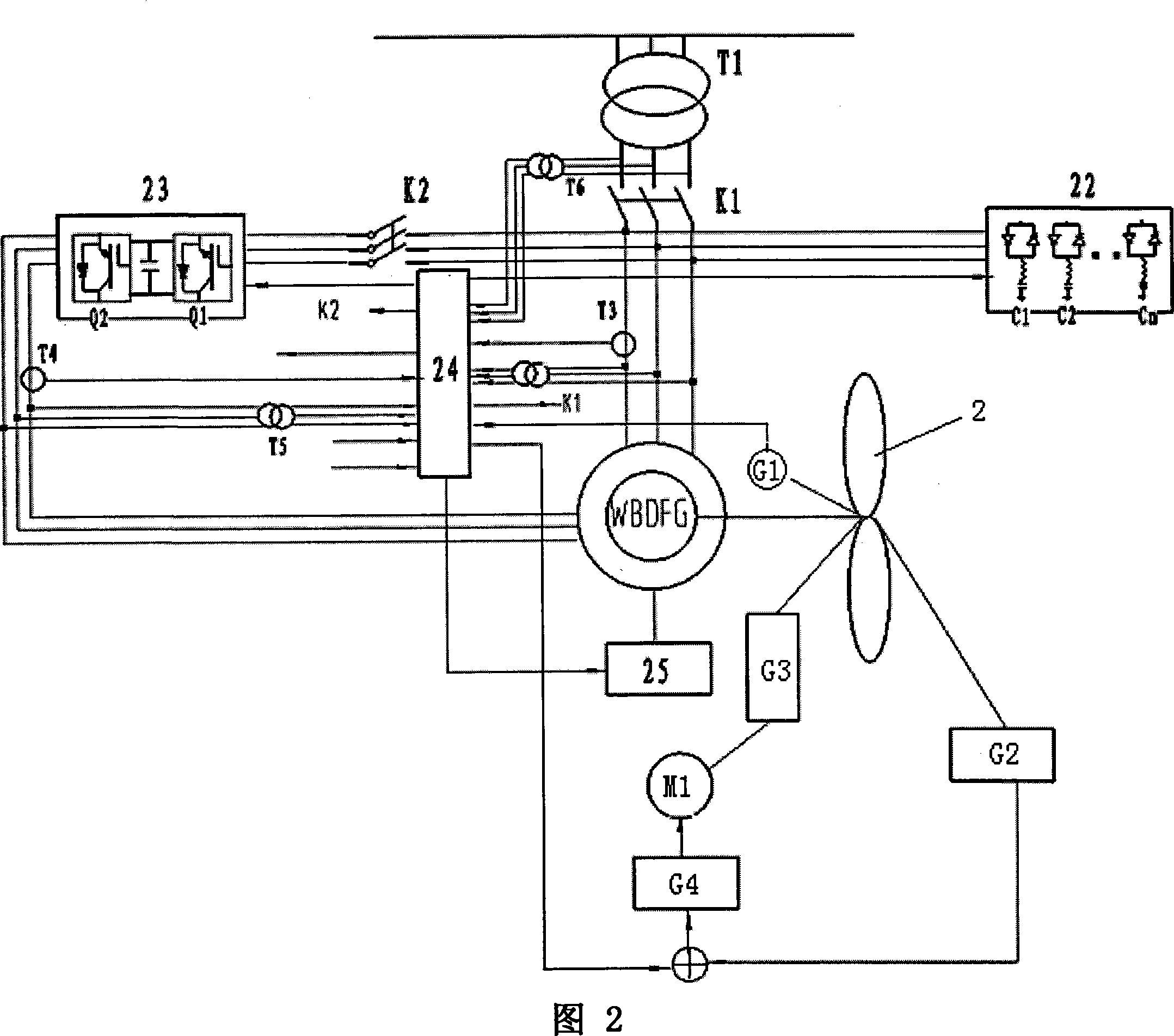

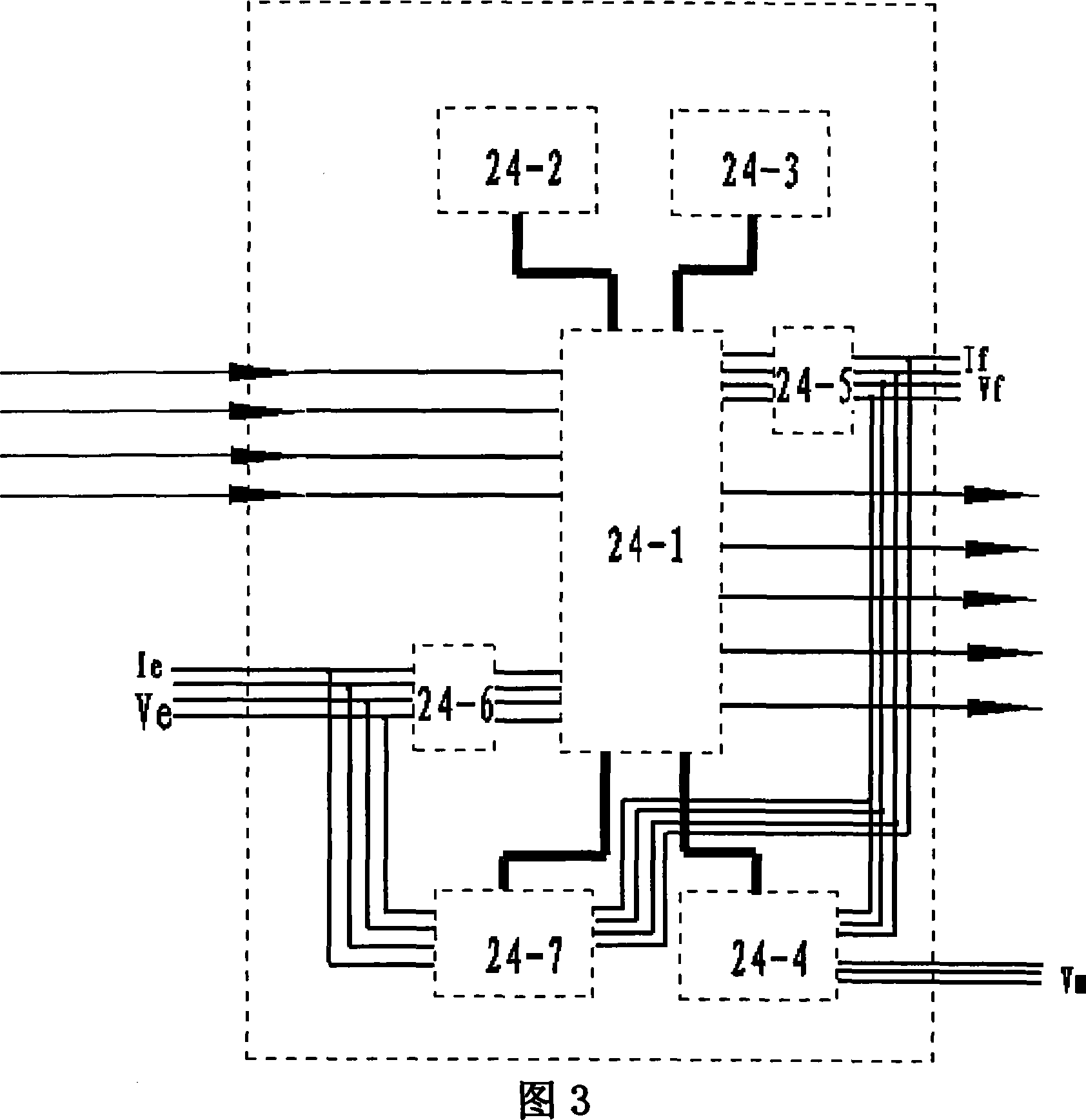

[0032] As shown in Figure 1-3.

[0033]A wire-wound telescopic rotor brushless doubly-fed generator, including a generator main body, a stator, a rotor, fan blades 2, and a hub 1, where the fan blades 2 are installed on the hub 1, and in the generator main body, the rotor rotates relative to the stator The structure setting of the fan blade 2 drives the hub 1 to drive the rotor to rotate, and the telescopic rotor generator and the exciter are arranged in the main body, the generator and the exciter rotor are coaxially installed, and the generator and the exciter are arranged in axial parallel structure; The generator and the exciter have independent magnetic circuits. The 15 pole pairs of the generator rotor winding are the same as the 14 pole pairs of the generator sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com