Electrical loading apparatus

An electric charging and power grid technology, applied in the field of electric charging devices, can solve the problems of inconvenient direct application and high cost, and achieve the effects of reducing maintenance amount, use cost and maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

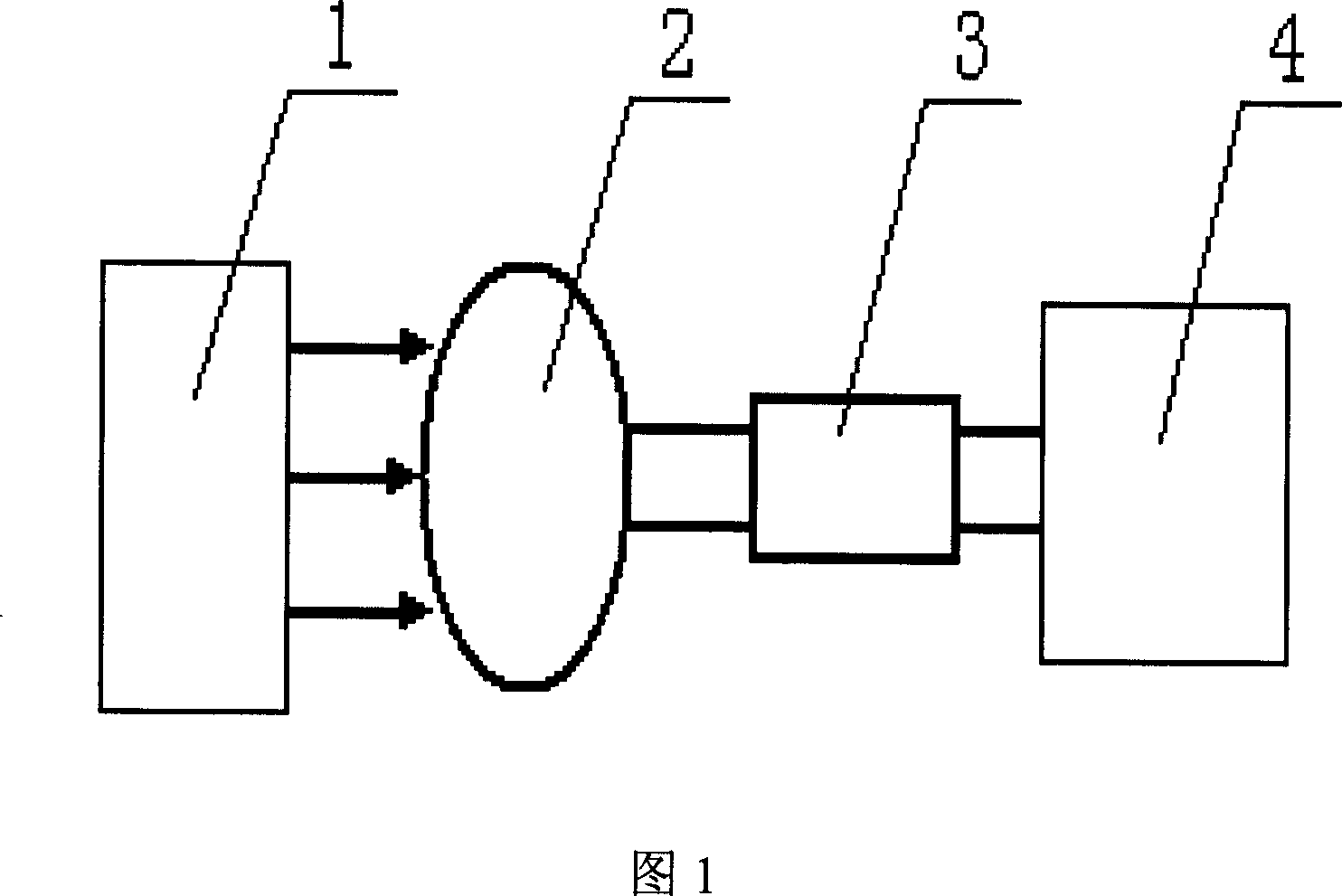

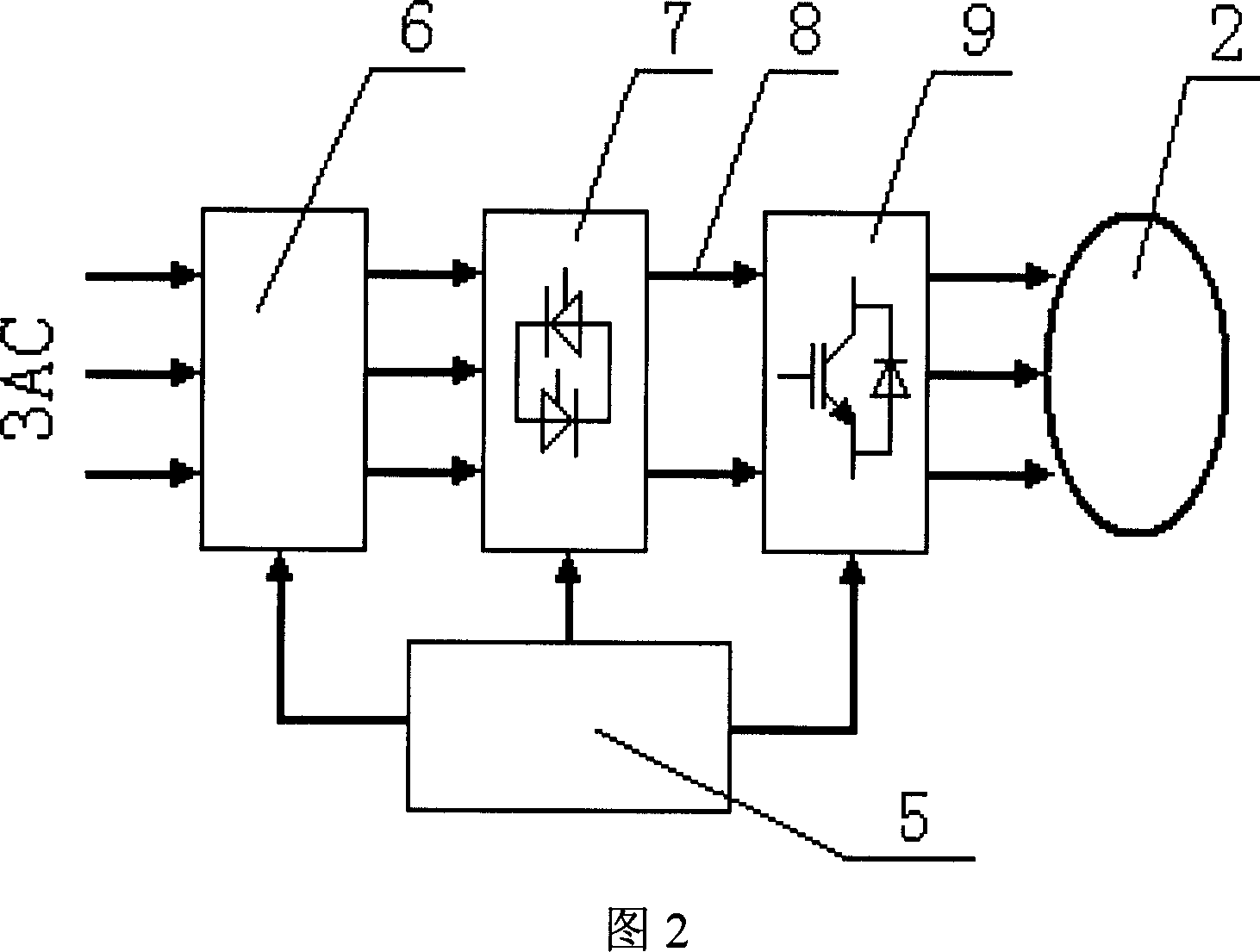

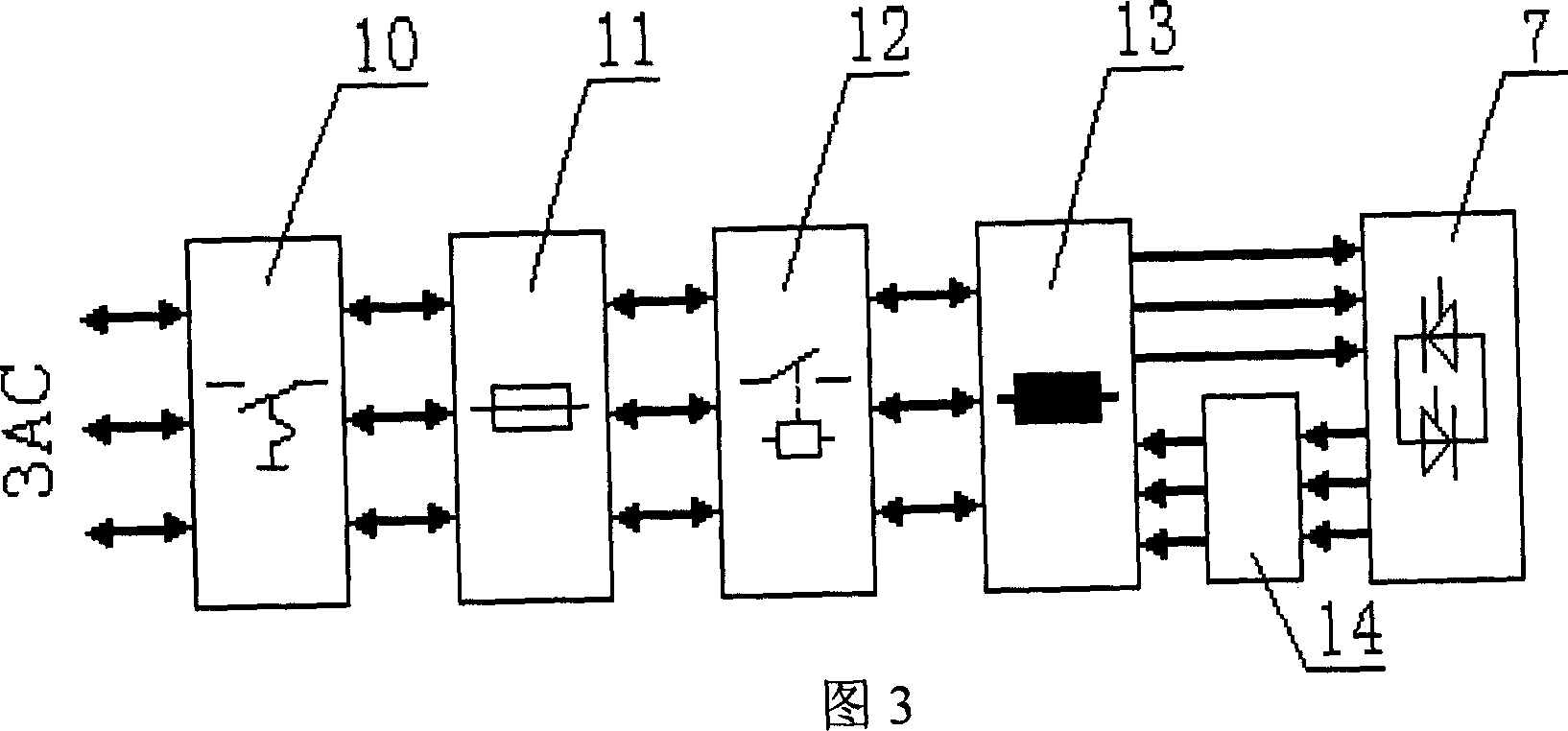

[0028] This example illustrates the electrical loading device provided by the present invention.

[0029] An AC variable frequency motor with a power of 132 kilowatts, model YVPCG280M2-67-A from Chongqing Dema Frequency Conversion Motor Research and Development Co., Ltd., and a dynamic torque sensor with a torque of 500 Nm of JZ-500 from Huxiang Measurement and Control Instrument Co., Ltd. , a model 6SE70 rectifier / regeneration unit with a power of 160 kW produced by Siemens, and a matching inverter unit with a power of 160 kW produced by Siemens and a power of 1.7 kW produced by Siemens Transformer, coupled with matching Siemens 535A reactor, Siemens 630A contactor, and Siemens 480A fuse, form the alternating current loading device.

[0030] Use this AC loading device to perform a performance test on a model 483 engine produced by Mitsubishi with a power of 90 kilowatts. Continuously tested for one month, the device can control the speed well within ±10rpm from the engine id...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com