Method for producing modified rosin ester resin composition for lithographic ink varnish and method for producing lithographic ink varnish

一种树脂组合物、平版油墨的技术,应用在油墨、天然树脂化学改性、应用等方向,能够解决难反应、污染飞墨、难以得到平版油墨充分粘弹性等问题,达到高树脂溶解性、环境改善有效、抑制印刷不适应性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

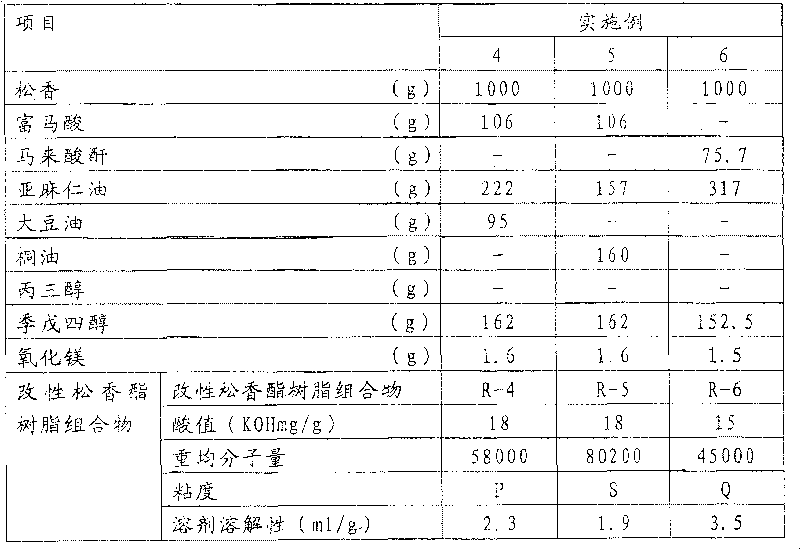

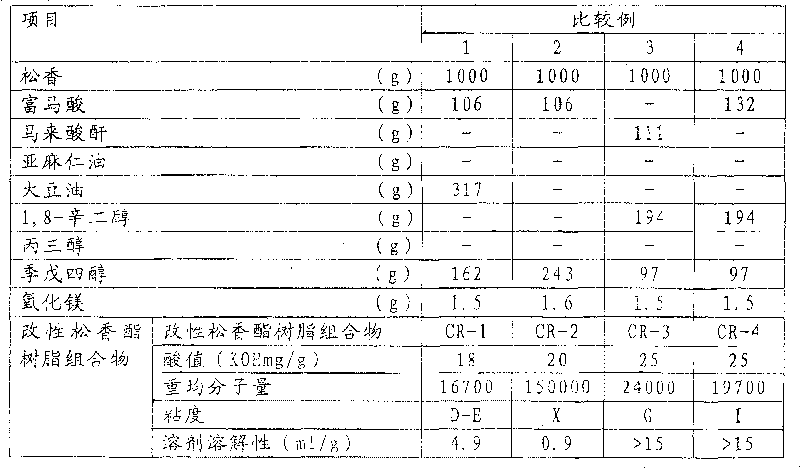

Examples

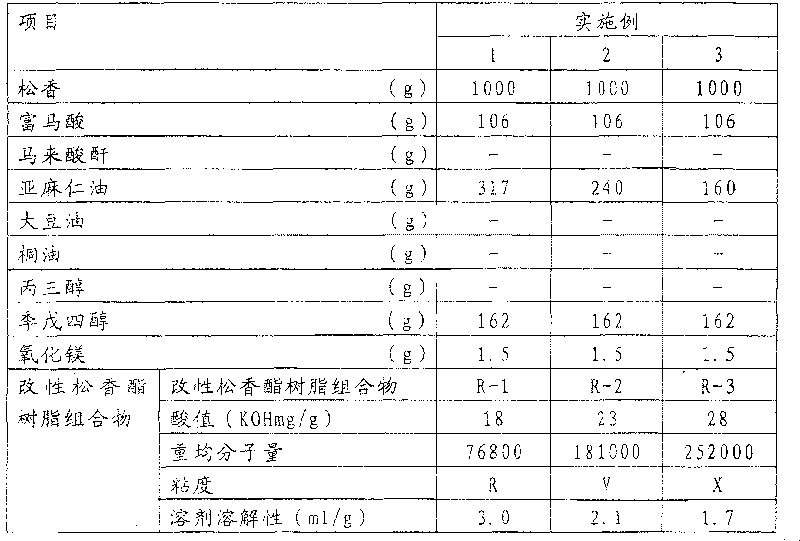

Embodiment 1

[0044] Add 1000 g of rosin (acid value 165KOHmg / g) and 106 g of fumaric acid to the reaction vessel, and heat and stir at 220° C. for 1 hour under nitrogen flow to obtain an acid value of 242 KOHmg / g containing acid-modified rosin and unreacted rosin After adding and mixing 317 g of linseed oil and 162 g of pentaerythritol, 1.5 g of magnesium oxide as a catalyst was added, stirred and mixed, and the temperature in the reaction vessel reached 161°C. Then, the reaction container was heated, and the temperature was raised to 270°C at a temperature increase rate of 30°C / hour for reaction, and then reacted at 270°C so that the acid value became 20KOHmg / g or less to obtain modified rosin ester resin and unreacted flax Modified rosin ester resin composition (R-1) for lithographic ink varnish of the present invention comprising kernel oil and pentaerythritol. About the obtained modified rosin ester resin composition (R-1) for lithographic ink varnishes, the acid value, weight average ...

Embodiment 2

[0051] Add 1000g of rosin (acid value 165KOHmg / g) and 106g of fumaric acid to the reaction vessel, and heat and stir at 200°C for 30 minutes under nitrogen flow to obtain an acid value of 240KOHmg / g containing acid-modified rosin and unreacted rosin After adding 240 g of linseed oil and 162 g of pentaerythritol and mixing them, then adding 1.5 g of magnesium oxide as a catalyst, stirring and mixing, the temperature in the reaction vessel reached 155° C. After reacting while heating up to 260°C at 30°C / hour, react at 260°C to make the acid value below 25KOHmg / g, and obtain the lithographic ink of the present invention containing modified rosin ester resin, unreacted linseed oil and pentaerythritol Modified rosin ester resin composition (R-2) for varnish. For the obtained modified rosin ester resin composition (R-2) for lithographic ink varnish, measure acid value, weight average molecular weight, viscosity and solvent solubility ( AF Solvent No. 7 solubility). The results are s...

Embodiment 3

[0053] Add 1000g of rosin (acid value 165KOHmg / g) and 106g of fumaric acid to the reaction vessel, and heat and stir at 200°C for 30 minutes under nitrogen flow to obtain an acid value of 240KOHmg / g containing acid-modified rosin and unreacted rosin After adding and mixing 160 g of linseed oil and 162 g of pentaerythritol, 1.5 g of magnesium oxide as a catalyst was added and stirred and mixed, and the temperature in the reaction vessel reached 160°C. Then, the reaction vessel was heated, and the temperature was raised to 260° C. while reacting at a heating rate of 30° C. / hour, and then reacted at 260° C. to make the acid value below 30 KOHmg / g to obtain a resin containing modified rosin ester resin and unreacted Modified rosin ester resin composition (R-3) for lithographic ink varnish of the present invention comprising linseed oil and pentaerythritol. The acid value, weight average molecular weight, viscosity, and solvent solubility (AF Solvent No. 7 solubility) of the obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| iodine value | aaaaa | aaaaa |

| Weight-average Molecular Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com