Mechanical pressure machine control method for slider stopping at certain point

A mechanical press, dead center position technology, applied in presses, manufacturing tools, etc., can solve problems such as life impact, braking performance decline, and inability to stop at the top dead center, achieve strong application and promotion value, and reduce adjustment. The number of times, the effect of improving the positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

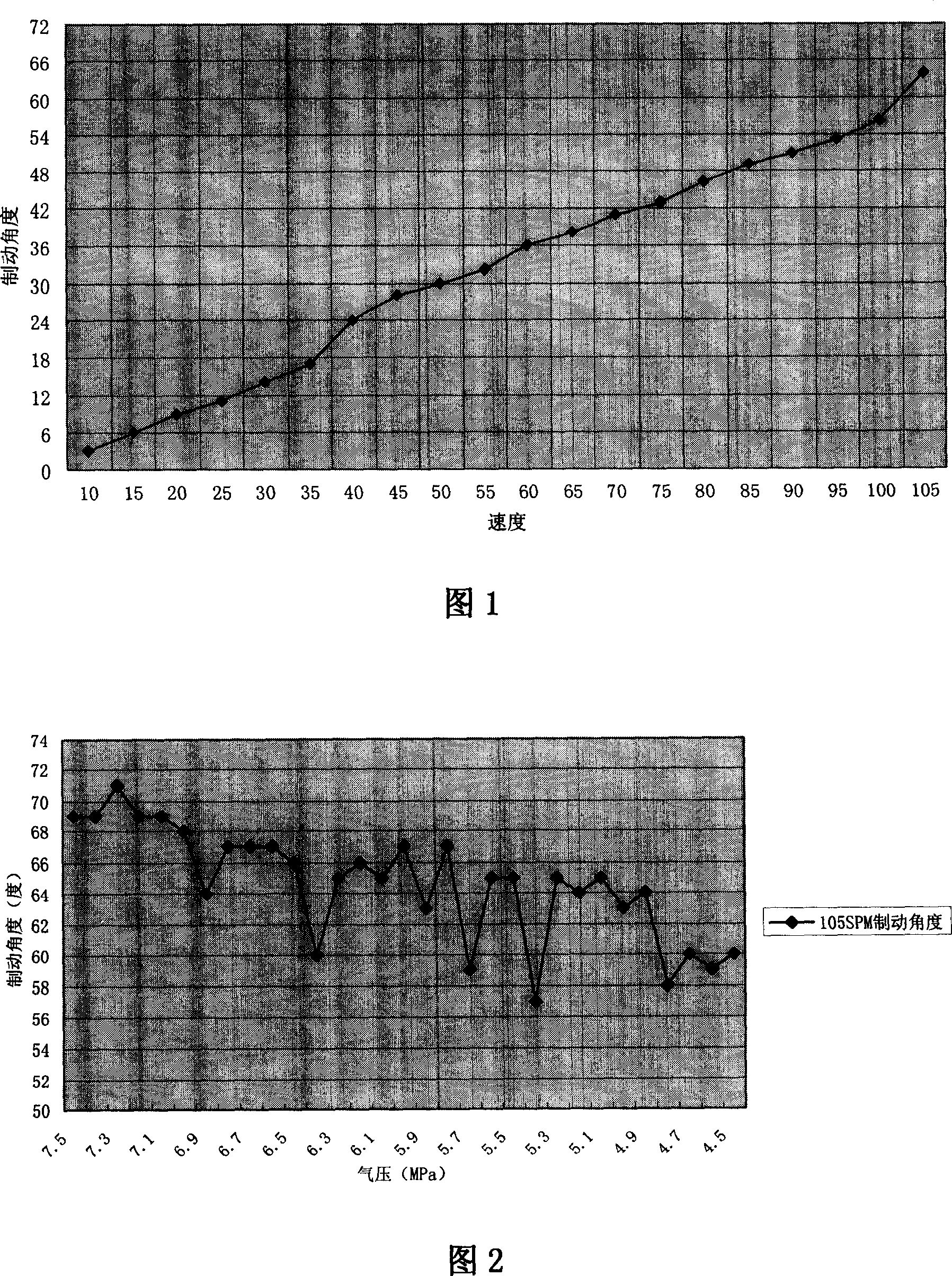

[0024] The relationship curve between the braking angle of the clutch and the speed of the slider is shown in Figure 1. Analyzing the graph, it can be approximated that the braking angle is directly proportional to the speed of the slider. Therefore, after we know the braking angles of two speed points, we can estimate the braking angles of other speed points. However, the braking angle is also related to the air pressure and the braking position of the clutch. At the same speed, when the air pressure is low, the braking angle is large, and when the air pressure is high, the braking angle is small. Refer to Figure 2 for the clutch braking angle curve at the same speed, because at the same speed, the braking angle is not only related to the air pressure, but also related to the position of the clutch brake, etc., so the air pressure and braking angle are not absolutely monotonous.

[0025] According to the above analysis results, the following braking algorithm is summarized: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com