Composite felt made of waste wool, waste terylene, and composite fiber

A technology of composite fiber and waste polyester, applied in the field of composite felt, which can solve the problems of hazards to passengers and non-recyclable reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

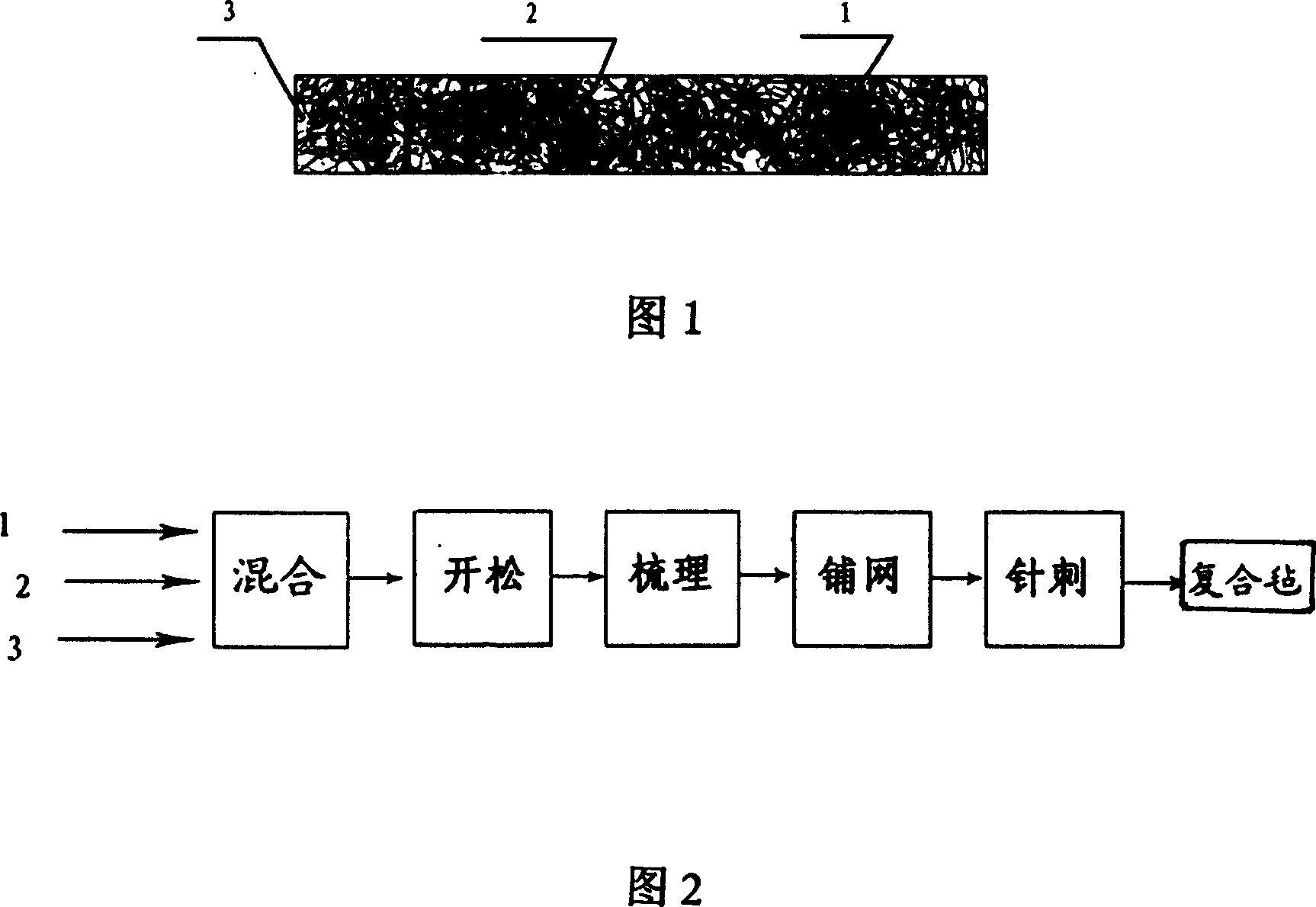

[0014] As shown in Fig. 1 and Fig. 2, it is a composite felt made of waste wool, waste terylene and composite fibers and a schematic diagram of the process structure. It is characterized in that: the method is:

[0015] Step 1. Mix 70% waste cotton fibers recovered by textile mills and regenerated fibers 1 of waste textiles thereof, 15% recycled polyester 2, and 15% ES fibers 3 containing polyethylene on the outside by weight percentage;

[0016] Step 2. Utilize the mature process of opening, carding, web laying, acupuncture, and winding to prepare the surface density of 50 g / m 2 composite felt.

Embodiment 2

[0018] Step 1. Mix 40% waste cotton fibers recovered by textile mills and regenerated fibers 1 of waste textiles, 30% recycled polyester 2, and 30% ES fibers 3 containing polyethylene on the outside by weight percentage;

[0019] Step 2. Use the mature process of opening, carding, laying, acupuncture, and winding to prepare an area density of 350 g / m 2 composite felt.

Embodiment 3

[0021] Step 1. Mix 20% waste cotton fibers recovered by textile mills and regenerated fibers 1 of waste textiles thereof, 40% recycled polyester 2, and 40% ES fibers 3 containing polyethylene on the outside by weight percentage;

[0022] Step 2. Use the mature process of opening, carding, laying, acupuncture, and winding to prepare an area density of 500 g / m 2 composite felt.

[0023] The car sound insulation, shockproof and heat insulation materials made of this material have the advantages of environmental protection, odorless and recyclable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com