Process for producing fabric with plant flavour

A production method and plant technology, applied in the field of fabrics, can solve problems such as troublesome use, and achieve the effect of energetic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

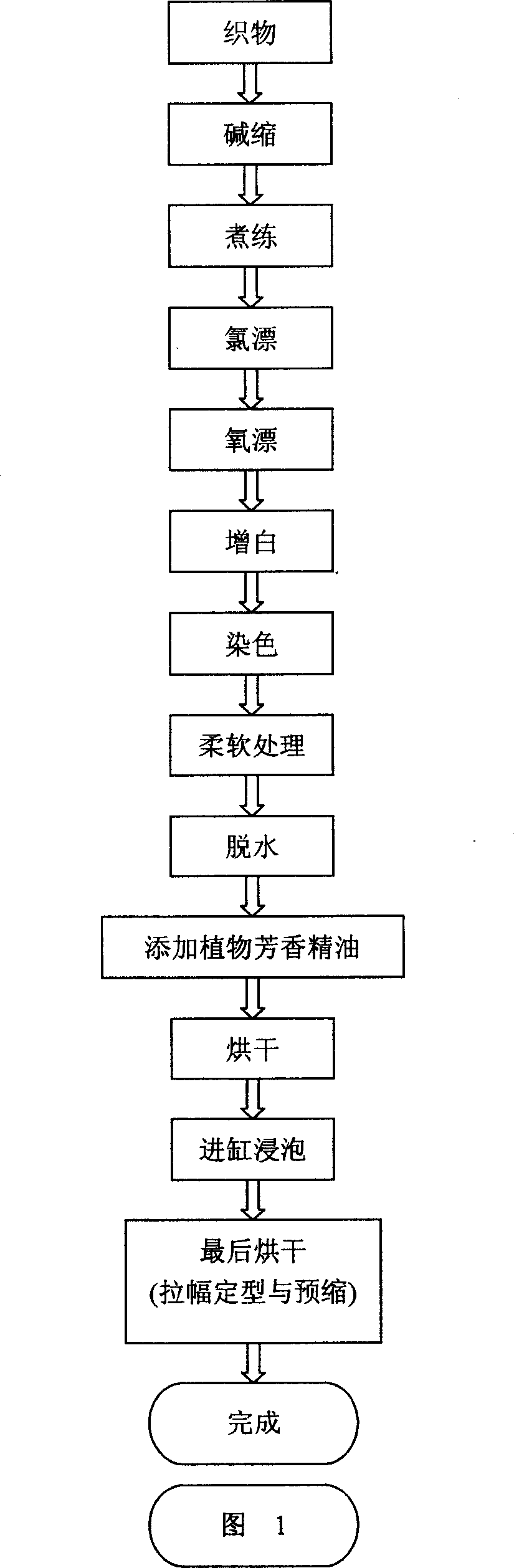

Image

Examples

Embodiment Construction

[0009] Take 180 g / m² cotton knitted jersey as an example.

[0010] Textile fabrics, fabric grey fabrics, after alkali shrinking, scouring, chlorine bleaching, oxygen bleaching, whitening, dyeing, softening, dehydration, and other traditional processes, add two more processes before the final drying (tentering and pre-shrinking). Improve a final drying process. Alkali shrinkage, scouring, chlorine bleaching, oxygen bleaching, whitening, dyeing, softening, dehydration and final drying (tentering and pre-shrinking) and other traditional techniques are all familiar to those skilled in the art. can be found in textbooks, such as "dyeing and finishing technology," China textile Press, 2, 3 volumes, in February 2000 the first edition 8th printing, author: Volume 2 designate Yongshan, 3 volumes Wu Kuan-ying. Therefore, there is no detailed description in this application.

[0011] 1. Alkali shrinkage: Alkaline shrinkage is to immerse the fabric in concentrated alkali in a relaxed state;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com