Large-area anti-fracture plate with 3-D coloured blank pattern and its making method

A production method and pattern technology, applied to building materials, manufacturing tools, building components, etc., can solve the problems of unrecognizable patterns, obvious artificial traces of printed patterns, and non-wearability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

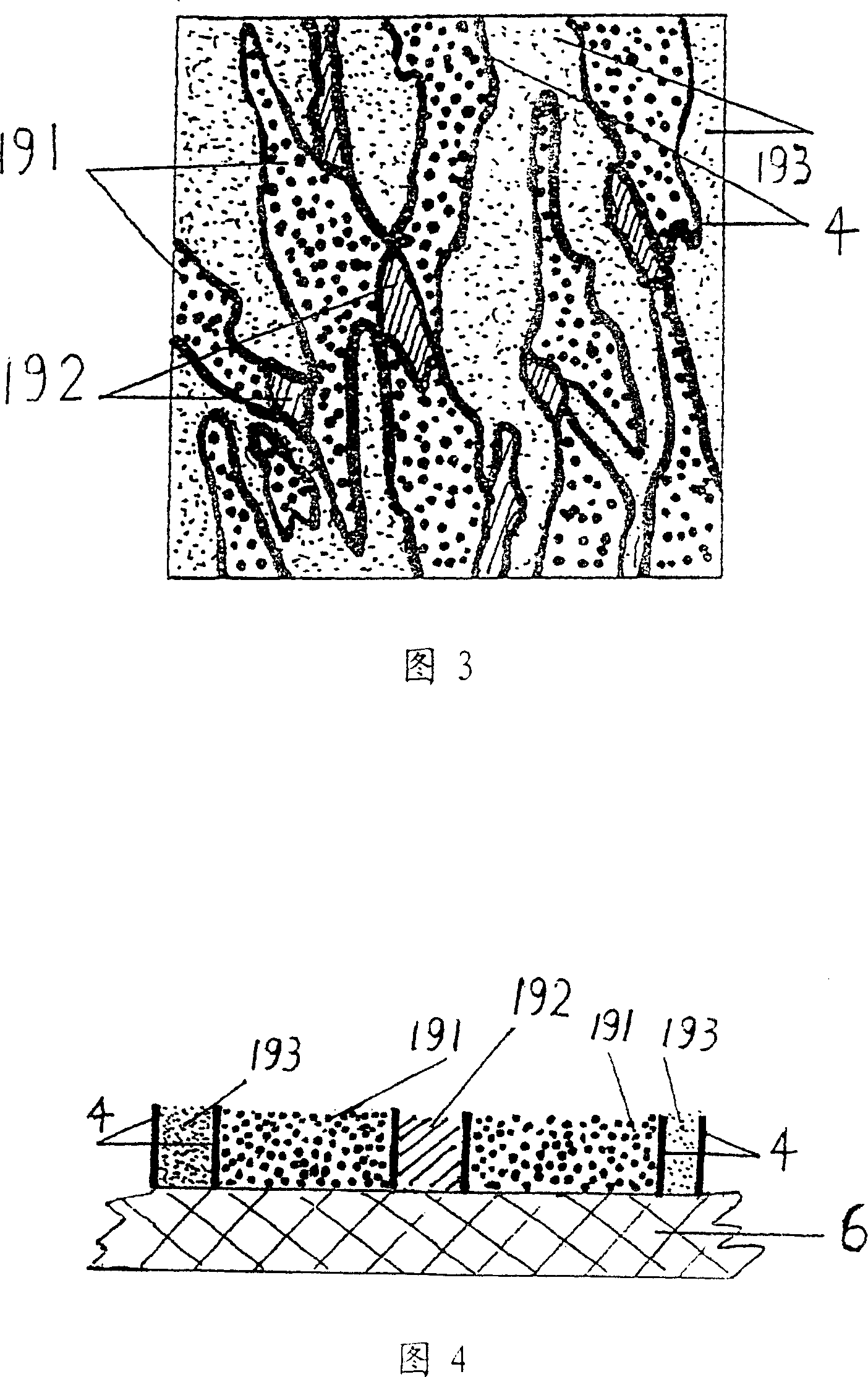

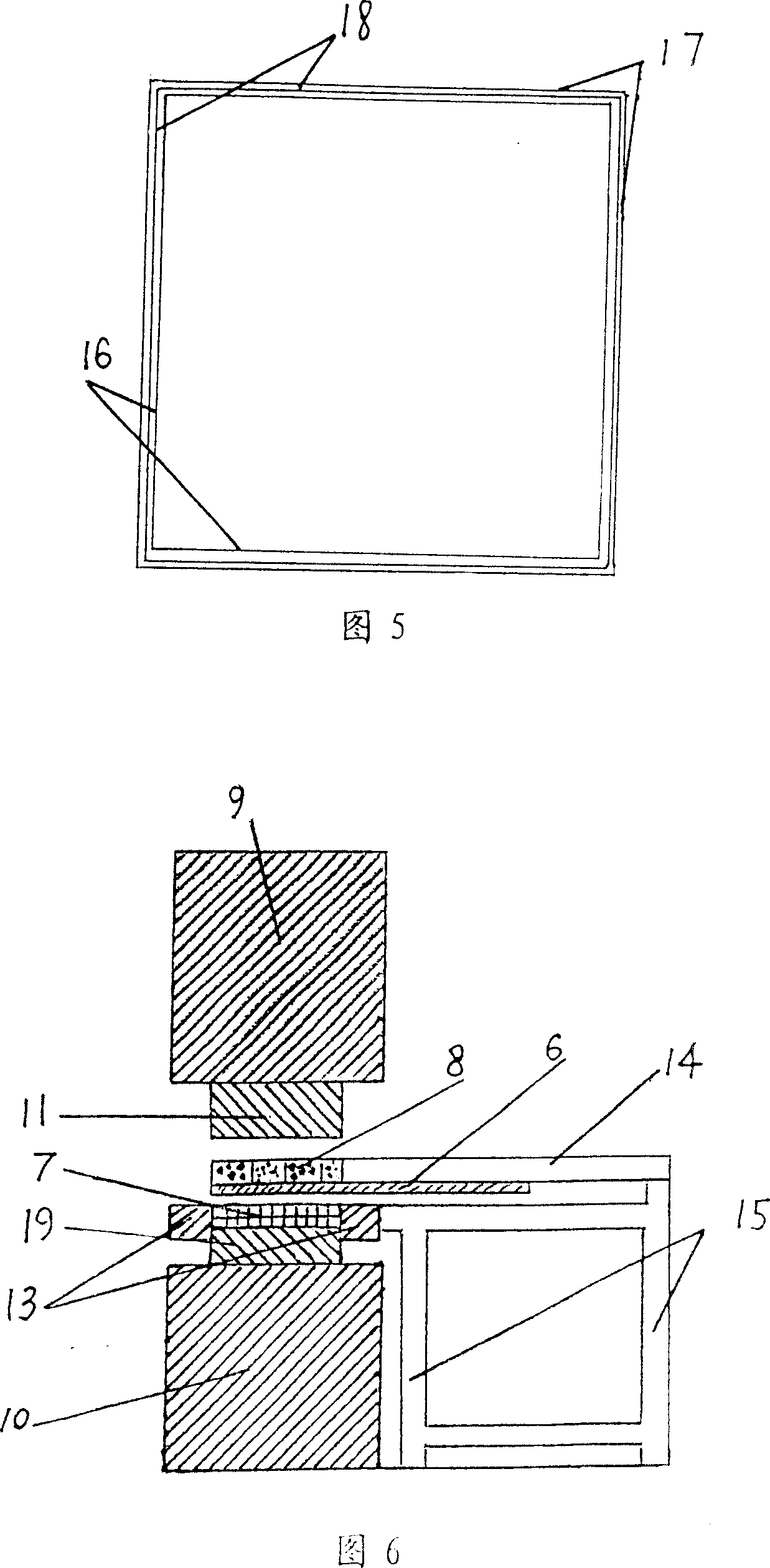

[0094] Below, with reference to the accompanying drawings and preferred embodiments, the specific implementation, structure, features and functions of the three-dimensional color green body pattern large-surface anti-folding plate and its manufacturing method according to the present invention will be described in detail as follows.

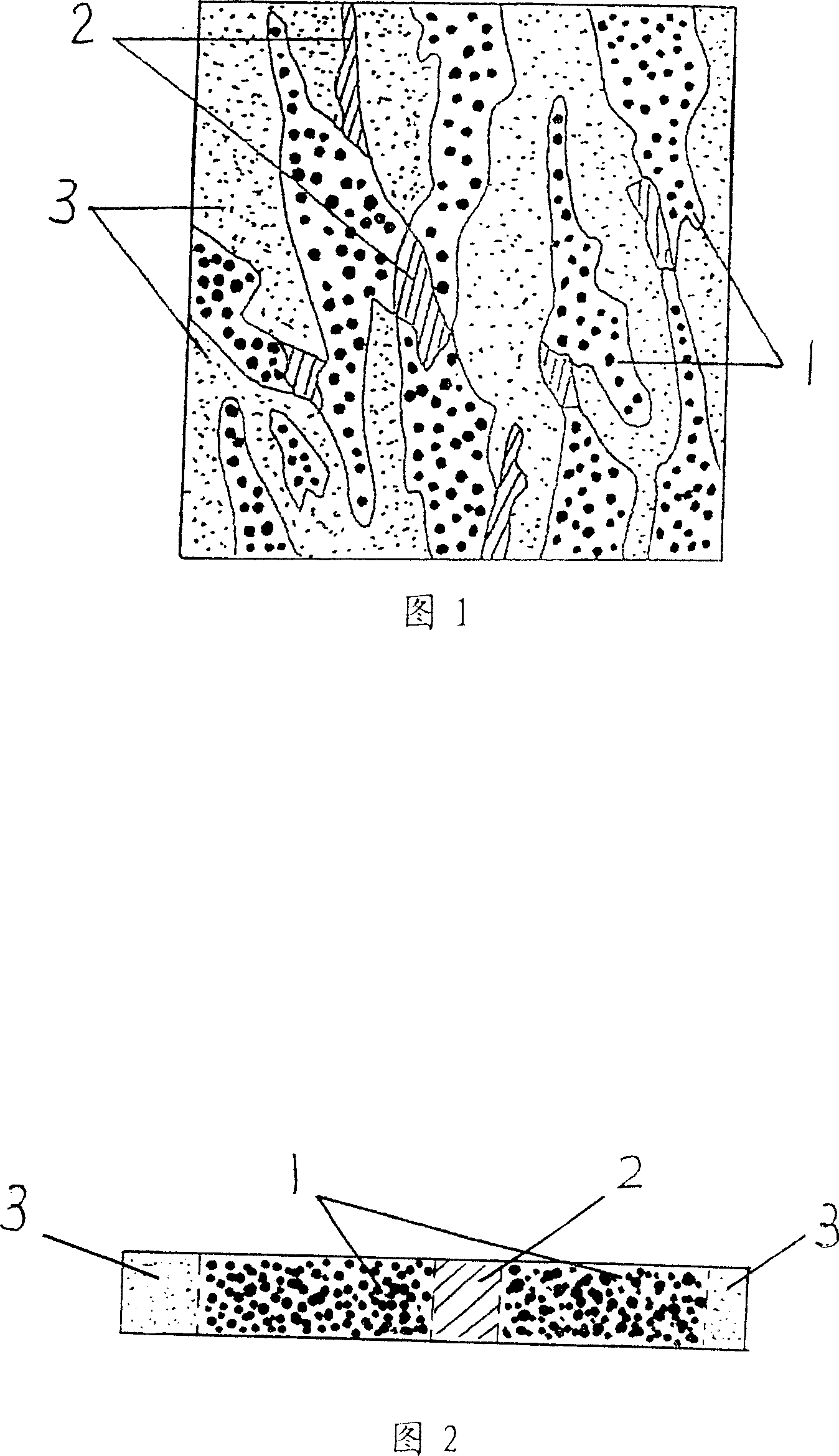

[0095] Please refer to FIG. 1 , which is a schematic diagram of the plane pattern structure of a porcelain imitation large-flowered green marble product with a size of 1200mm×1200mm×3mm, which is an embodiment of a three-dimensional color body pattern large-surface anti-folding plate and its manufacturing method. The large black dot part 1 pattern area represents the dark green area of the porcelain material containing ceramic fiber or glass fiber; the small black dot part 3 pattern area represents the black area of the porcelain material containing ceramic fiber or glass fiber; the oblique line part 2 pattern Areas represent gray areas of por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com