Substrate fixing clamp of magnetic sputtering instrument

A technology for fixing fixtures and substrates, which can be used in sputtering plating, semiconductor/solid-state device manufacturing, ion implantation plating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

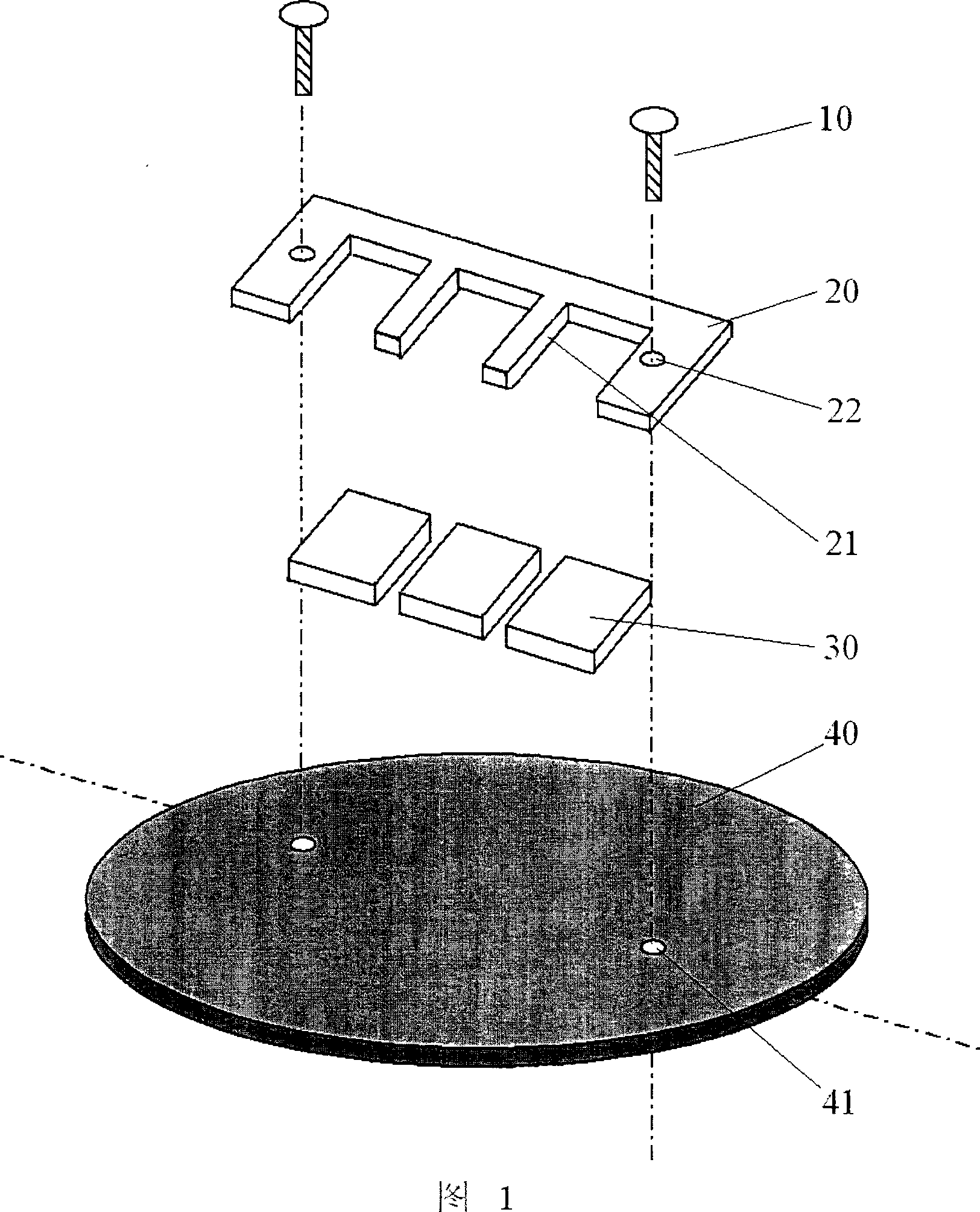

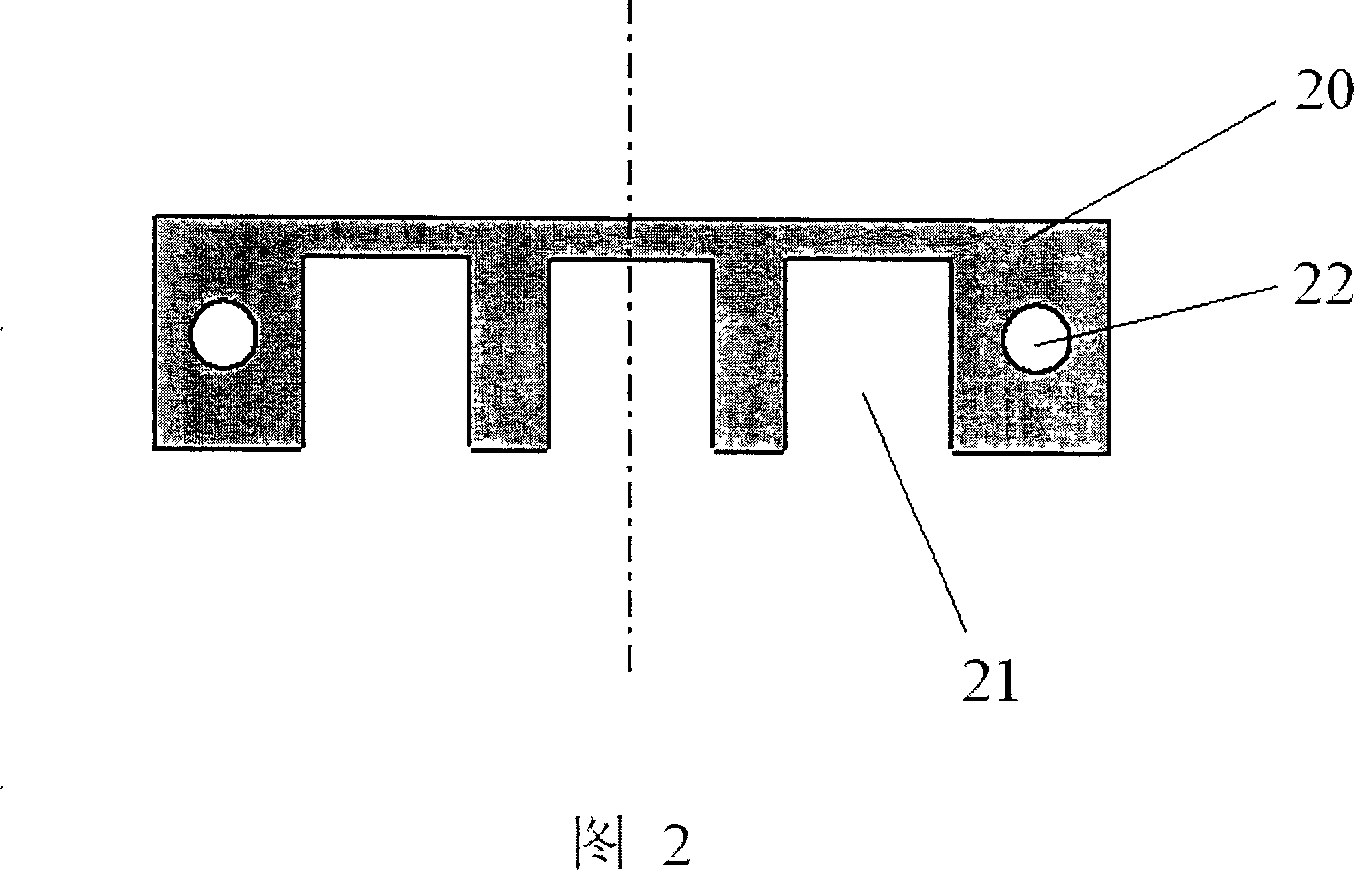

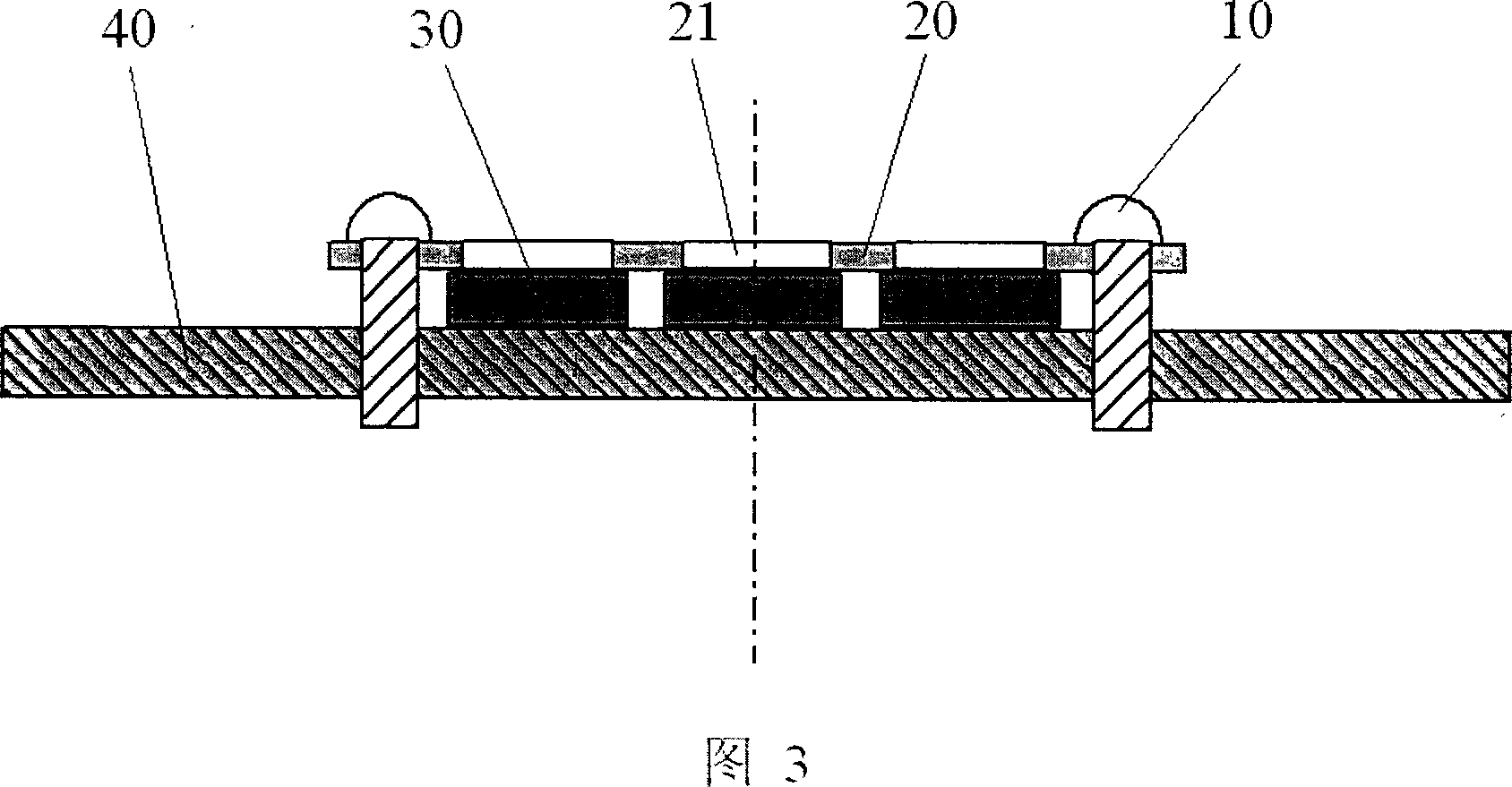

[0014] Please refer to shown in Fig. 1~3, a kind of fixture that is used for magnetron sputtering instrument substrate comprises a cover sheet (20), and this cover sheet main body is rectangular, and material can be steely, and there are three on its one side. A square notch (21) is used to expose the surface of the substrate, with a through hole (22) at each end; a substrate support (40), which is circular and has two screw holes (41) inside, The hole pitch is consistent with that of the through holes on the cover; the substrate (30) is placed under the notch of the cover, and is fixed between the cover and the substrate support by screws (10). The substrate is sandwiched between the cover slip and substrate holder and secured with screws.

[0015] The working process of this fixing fixture is: at first the cover sheet (20) is placed on the substrate holder (40), the through hole (22) on the cover sheet (20) and the screw hole on the substrate holder (40) (41) align, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com