Management system and method for feeder of plaster machine

A management method and management system technology, applied in the field of placement machine feeder management system, can solve the problem of inability to track the feeder status and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention takes surface mount technology (Surface Mounting Technology, SMT) feeding equipment as an example.

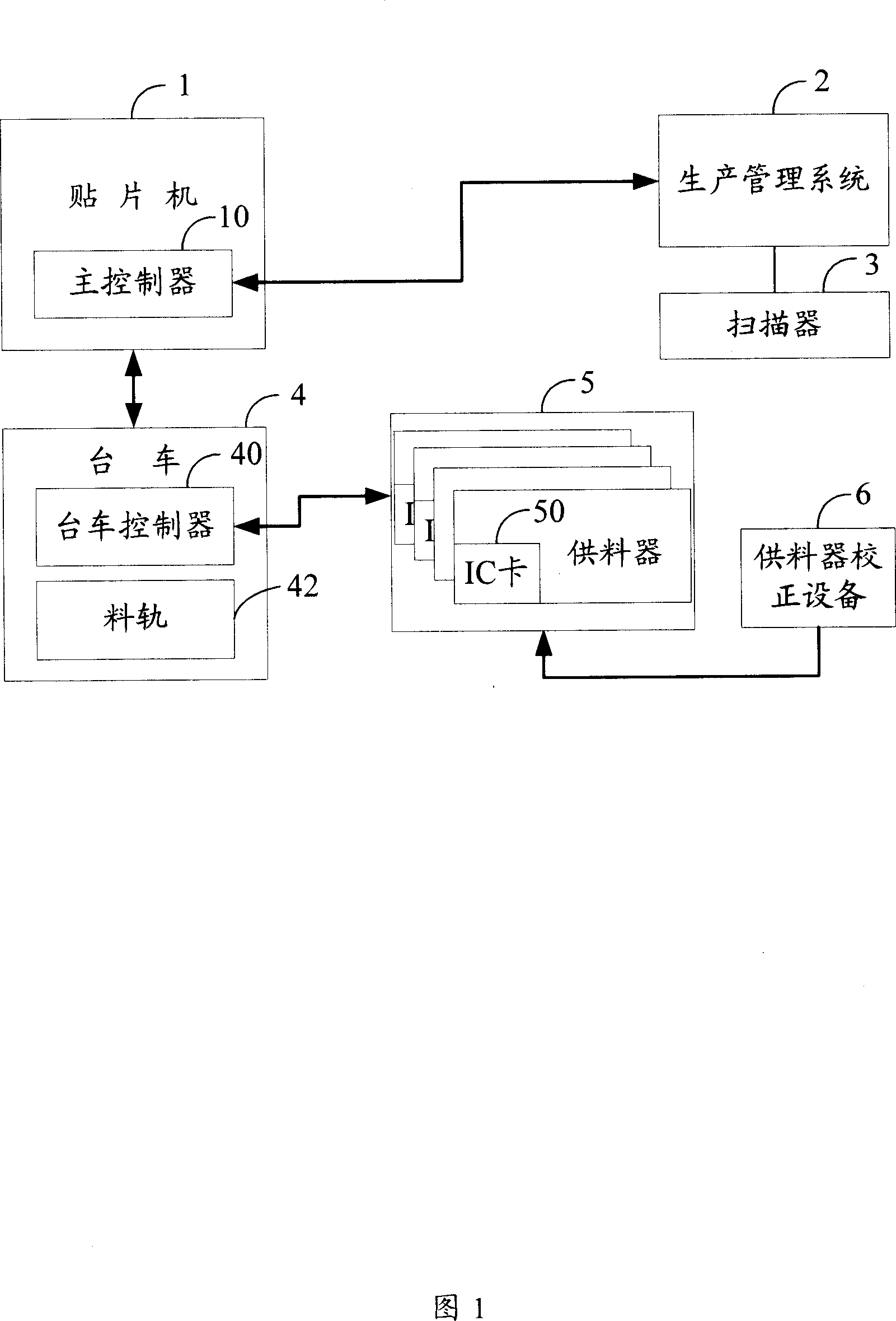

[0023] As shown in FIG. 1 , it is a hardware architecture diagram of a preferred embodiment of the chip mounter feeder management system of the present invention. The placement machine feeder management system mainly includes a placement machine 1 , a production management system 2 , a scanner 3 , a trolley 4 , a plurality of feeders 5 and a feeder calibration device 6 . Wherein, the mounter 1 is connected with the production management system 2 and the trolley 4, and the material on the feeder 5 can be accurately installed on a fixed position of a printed circuit board through the mounter 1 . The placement machine 1 includes a main controller 10 . The trolley 4 is connected to the feeder 5 , and a trolley controller 40 and a plurality of material rails 42 are installed in the trolley 4 for controlling the placement machine 1 to communicate with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com