Electrically conductive shield for refrigerator

A conductive shielding and refrigerator technology, which is applied in refrigerators, refrigeration and liquefaction, circuits, etc., can solve the problems of expensive bismuth alloys and lack of thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

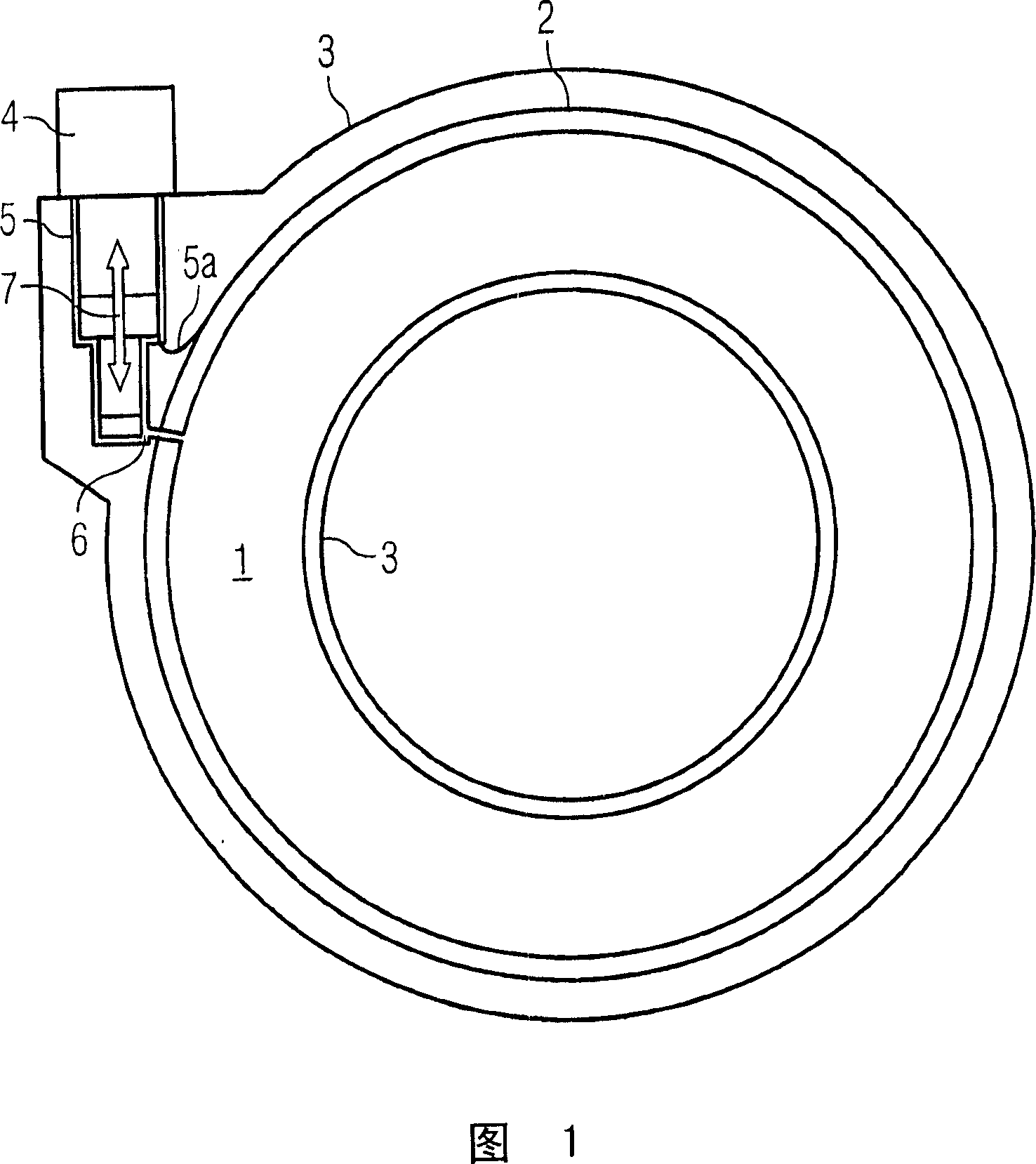

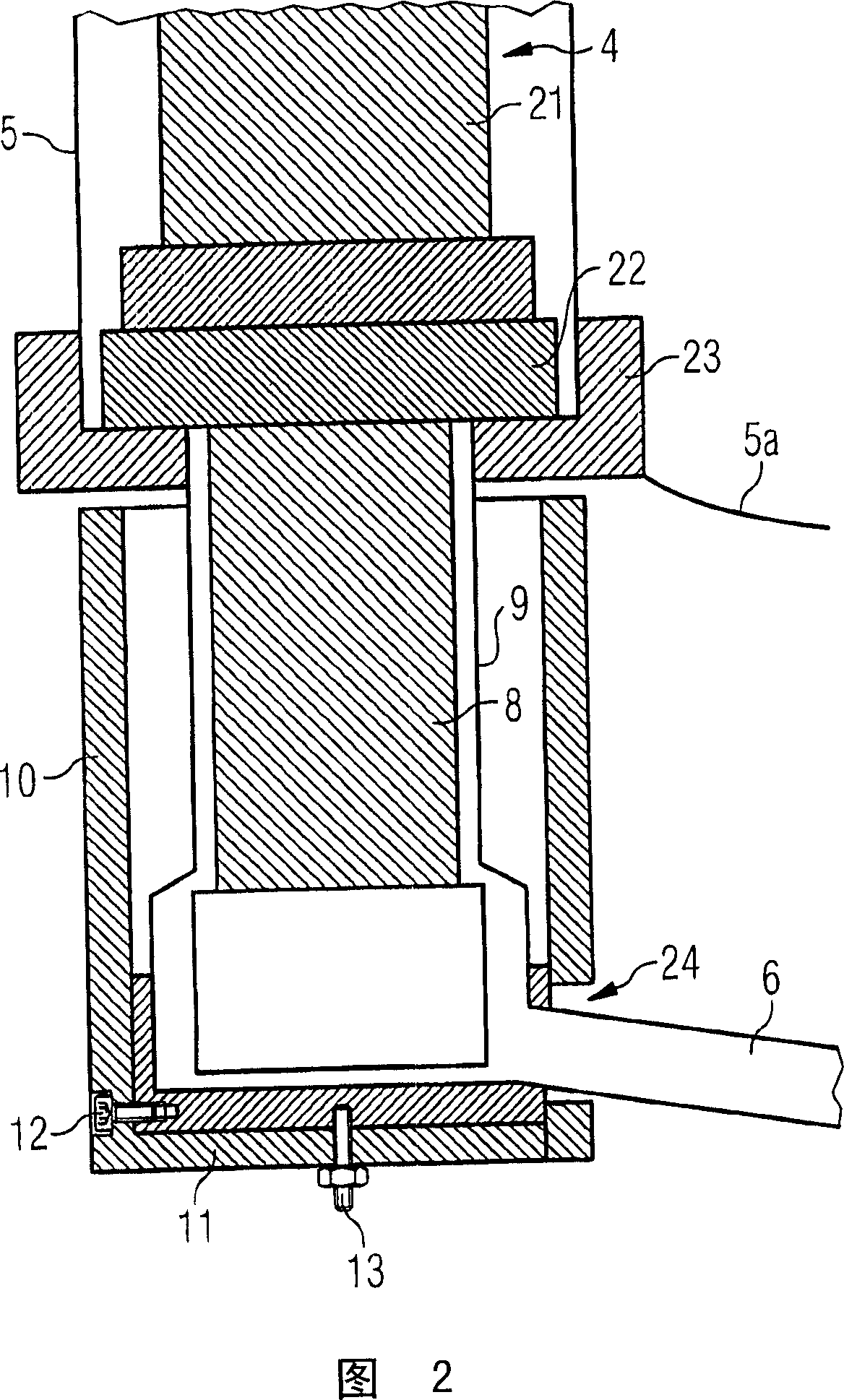

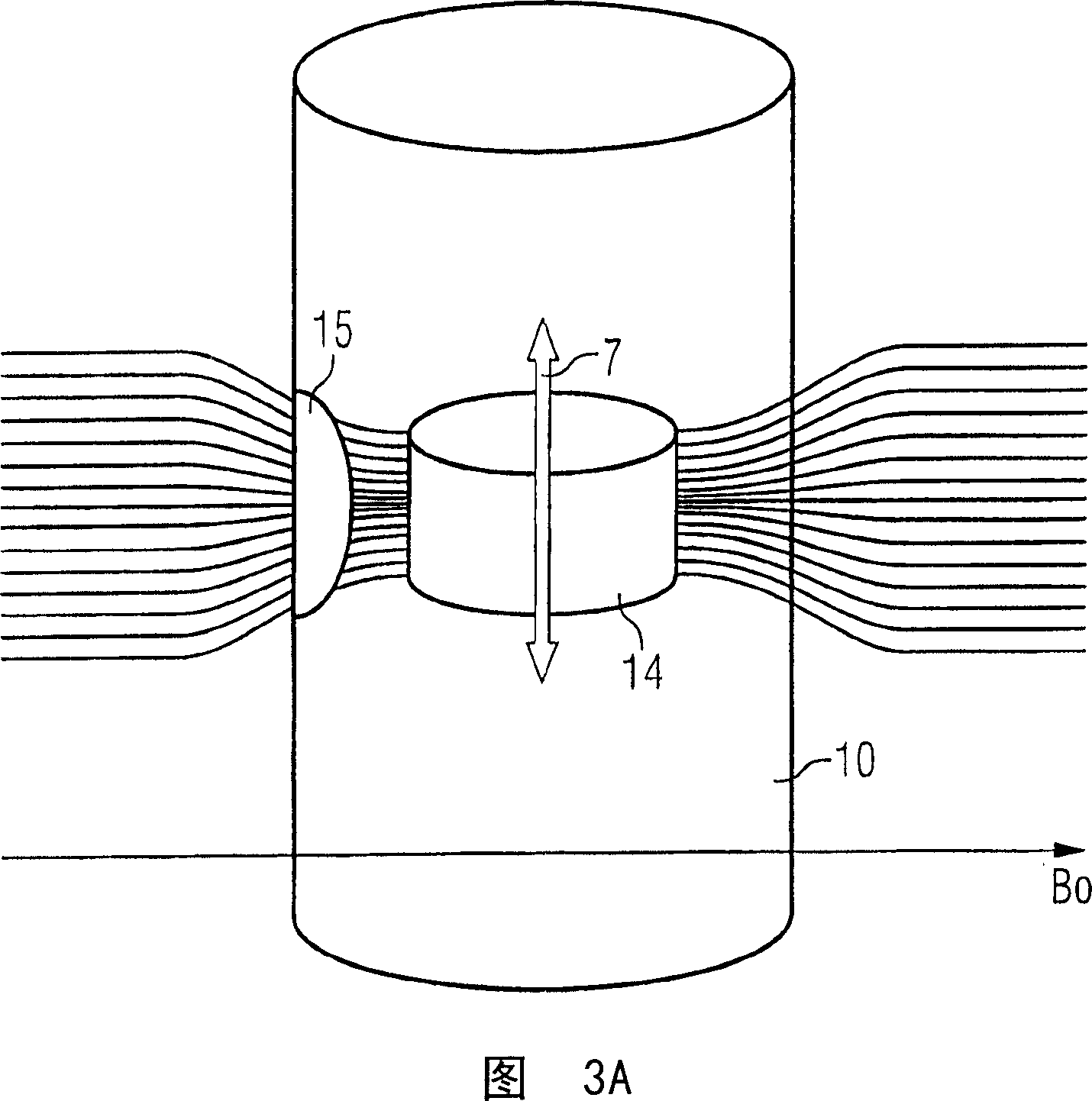

[0014] FIG. 1 shows a schematic diagram of a cryogenic magnet system equipped with a refrigerator 4 in a connection sleeve 5 . The particular cryogenic magnet system shown is an MRI magnet system. A liquid cryogen container 1 containing a superconducting magnet (not shown) is surrounded by one or more heat shields 2 which in turn are completely surrounded by a vacuum jacket 3 . Refrigerator 4 is detachably assembled to the magnet system, and is thermally and mechanically connected by connection sleeve 5, so as to cool the heat shield 2 through thermal connection 5a, which may be copper braided wire or Any other suitable known thermal connection. Although not required by the present invention, the interior of the connecting sleeve 5 may communicate with the interior of the cryogen container 1 , for example via a tube 6 . The refrigerator 4 can then recondense the evaporated refrigerant gas and convey it back to the refrigerant container 1 via the line 6 . During operation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com