Automatic sheet feed mechanism

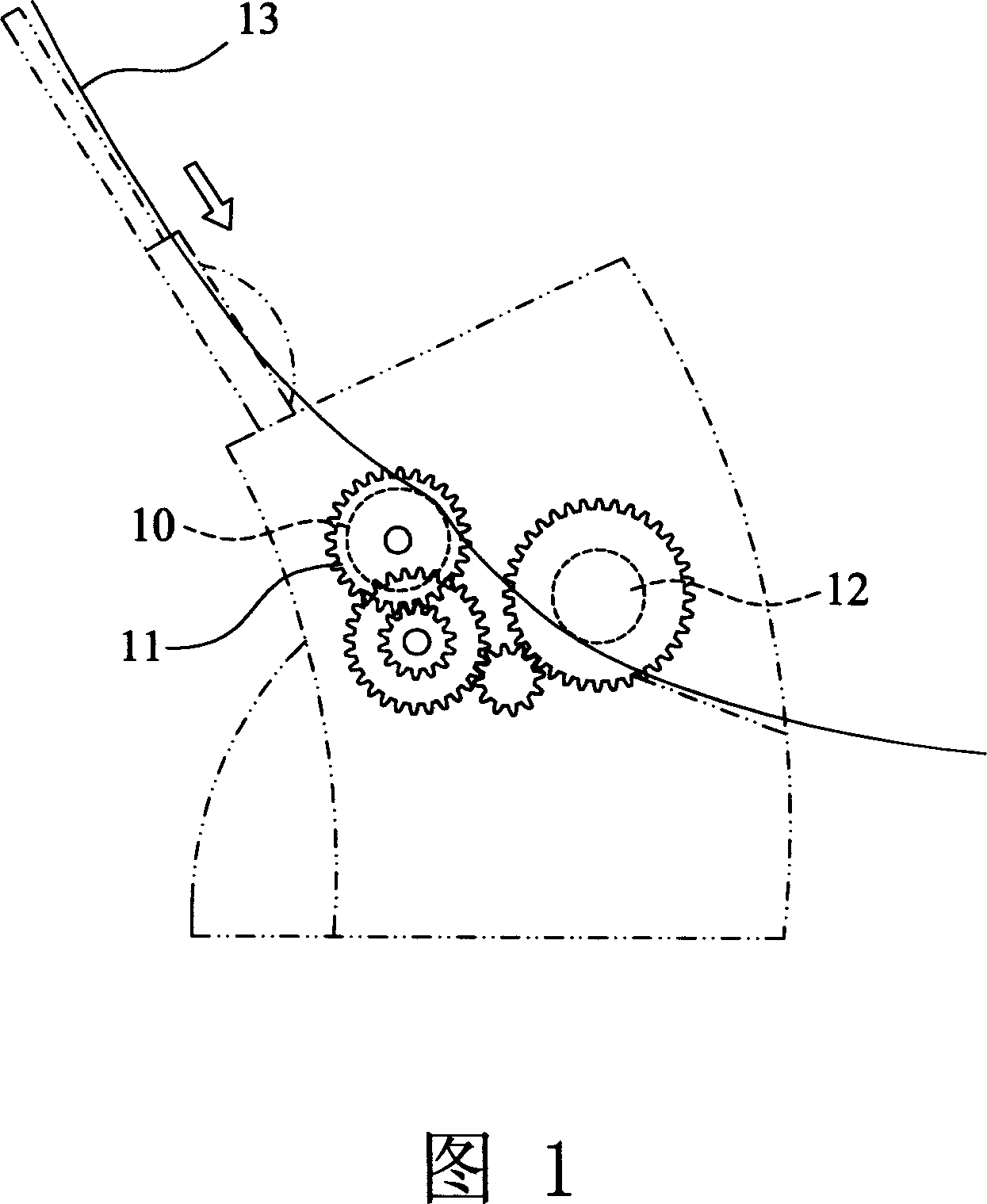

A paper-feeding and automatic technology, which is applied in the field of automatic paper-feeding mechanism, can solve the problems of paper pulling, difficult handling of paper picking/separating, multi-sheet feeding or paper jamming, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

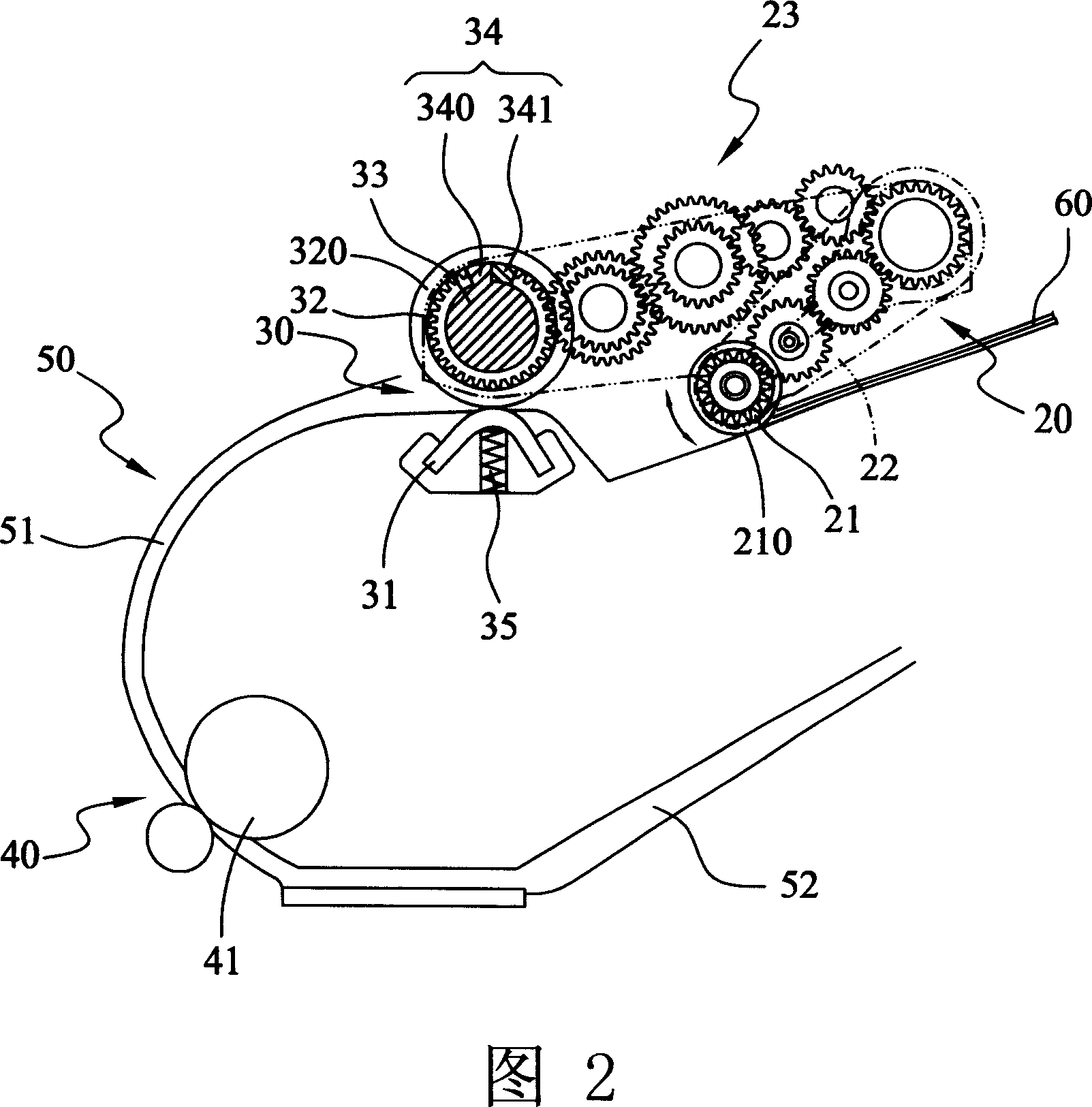

[0041] The automatic paper feeding mechanism disclosed in the present invention can be applied to fields such as multifunctional business machines, facsimile machines, copiers, scanners, etc. In the following specific embodiments of the present invention, it will be applied to scanners and multifunctional business The machine is described as the preferred embodiment of the present invention.

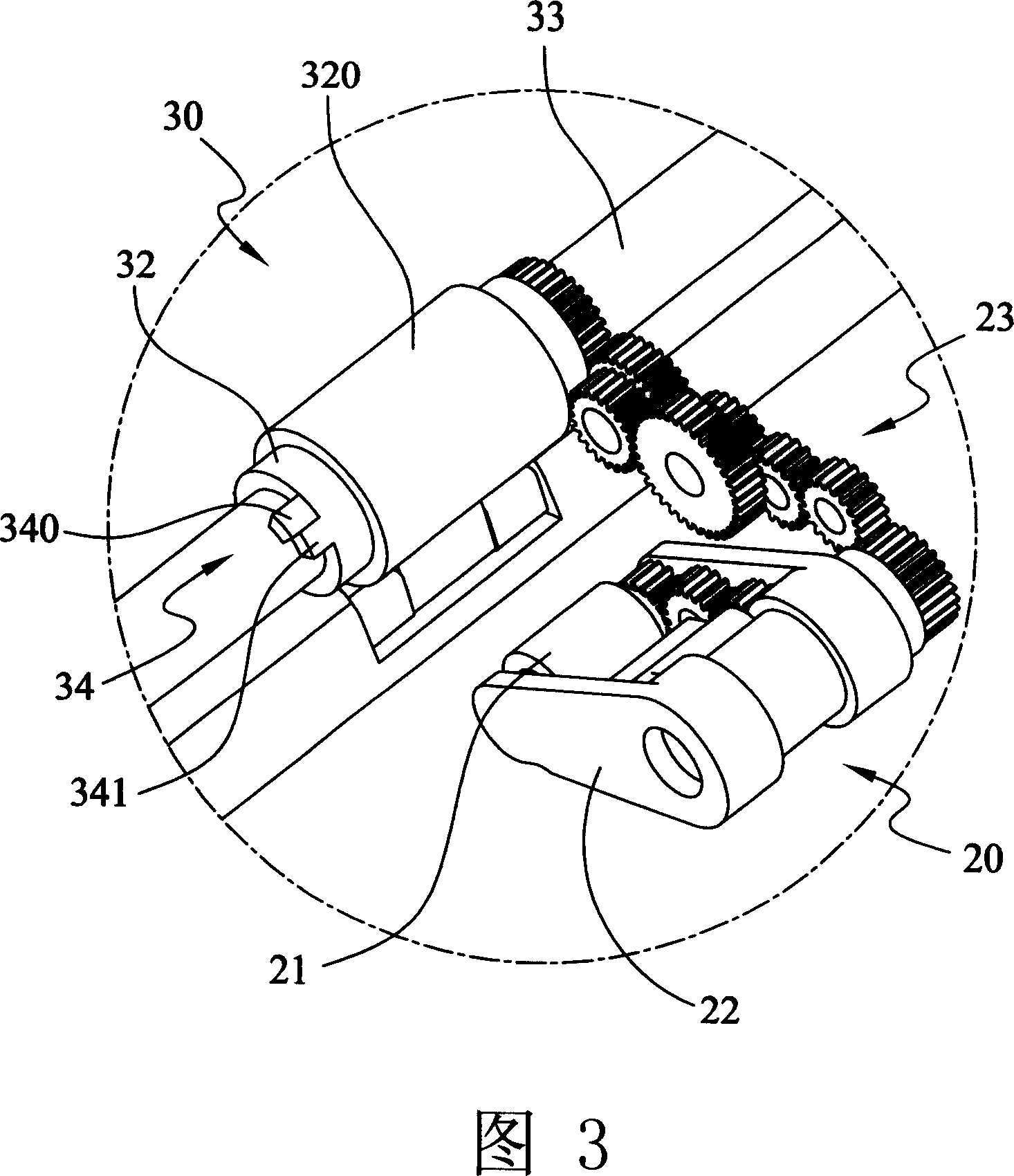

[0042] Please refer to Fig. 2, the present invention shown in the figure mainly comprises a paper-fetching assembly 20, a paper-separating assembly 30, a paper-feeding assembly 40, and a housing 50, forming a paper that can be moved when each assembly is running. 60 passes through the paper fetching assembly 20 , the paper separating assembly 30 , the paper feeding guide rail 51 formed by the housing 50 , and the paper feeding assembly 40 in sequence to reach the entrance 52 of the next operation.

[0043] Wherein, the above-mentioned paper picking assembly 20 includes a paper picking ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com