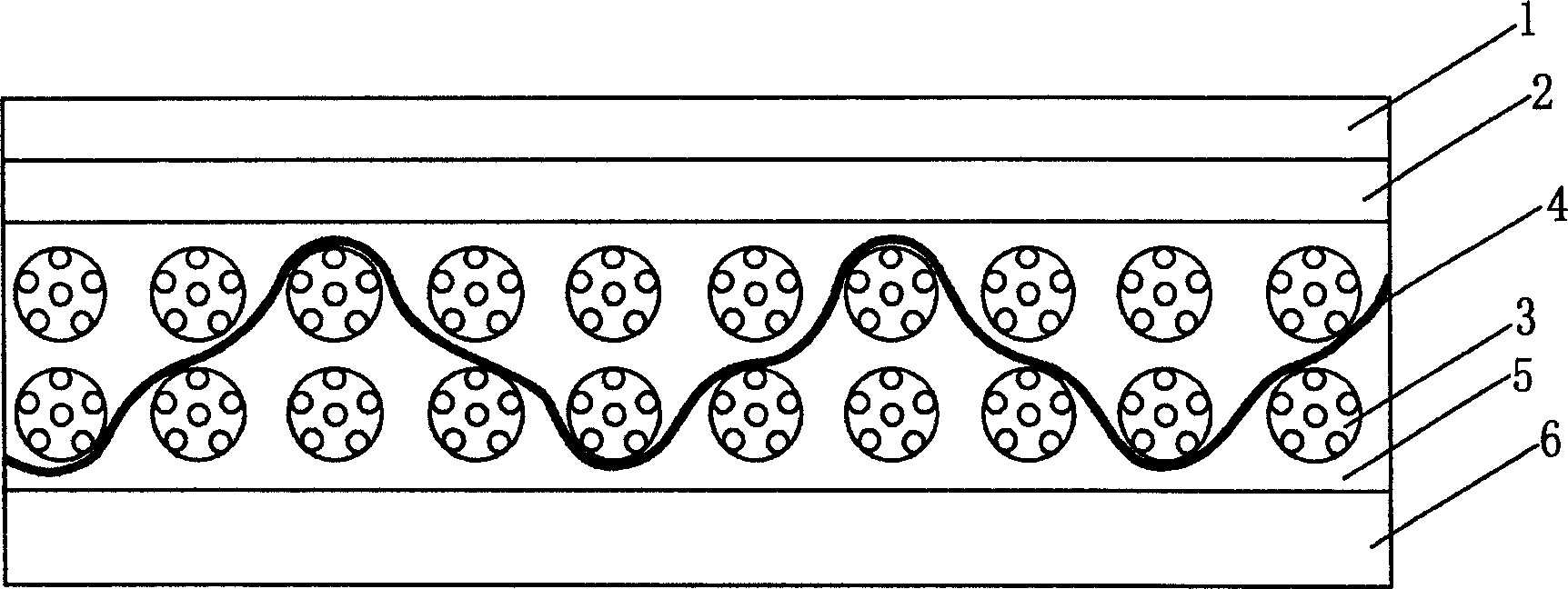

Blanket in use for papermaking

A blanket and fiber technology, applied in the field of dehydration equipment for papermaking, can solve the problems of poor wear resistance and short service life, and achieve the effects of improving shape stability, service life and compressibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] It is suitable for corrugated base paper and large roll diameter blind hole press.

[0027] Warp yarn: 0.2mm*6*1 Warp density: 145 threads / 10 cm

[0028] Weft yarn: 0.3 mm Weft density: 60 threads / 10 cm

[0029] Surface fiber: 11D nylon 46+25D nylon 66: 30%;

[0030] Among them, 11D nylon 46: 25D nylon 66 = 20%: 10%.

[0031] Core fiber: 25D nylon 66: 37%.

[0032] Back layer fiber: 25D nylon 46: 33%.

[0033] Air permeability of blanket: 60-65cfm

[0034] Blanket thickness: 3.5 mm

Embodiment 2

[0036] It is suitable for common dried noodle box board paper and a vacuum pressing part.

[0037] Warp yarn: 0.2mm*4*2 Warp density: 150 strands / 10 cm

[0038] Weft yarn: 0.3 mm Weft density: 60 threads / 10 cm

[0039] Surface fiber: 11D nylon 46+25D nylon 46: 25%;

[0040] Among them, 11D nylon 46: 25D nylon 46 = 15%: 10%.

[0041] Core fiber: 25D nylon 66: 35%.

[0042] Back layer fiber: 25D nylon 46:40%.

[0043] Air permeability of blanket: 65-75cfm

[0044] Blanket thickness: 3.3 mm

Embodiment 3

[0046] It is suitable for corrugated paper and blind air press.

[0047] Warp yarn: 0.2mm*6*1 Warp density: 78 strands / 10 cm

[0048] Weft yarn: 0.3 mm Weft density: 60 threads / 10 cm

[0049] Surface fiber: 10D nylon 66+25D nylon 46: 30%;

[0050] Among them, 10D nylon 66: 25D nylon 46 = 15%: 15%.

[0051] Core fiber: 25D nylon 66: 32%.

[0052] Back layer fiber: 25D nylon 46: 38%.

[0053] Air permeability of blanket: 60-70cfm

[0054] Blanket thickness: 3.7 mm

PUM

| Property | Measurement | Unit |

|---|---|---|

| gas permeability | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| gas permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com