Concrete complex building of steel meshwork framework, and construction procedure

A technology of concrete and frame, applied in the direction of building structure, building, truss structure, etc., can solve the problems of poor flexibility, strength, rigidity, poor overall stability, and high cost of industrialization of external hanging panels, so as to facilitate centralized organization and ensure concrete Quality and strength, craftsmanship intersect with a clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

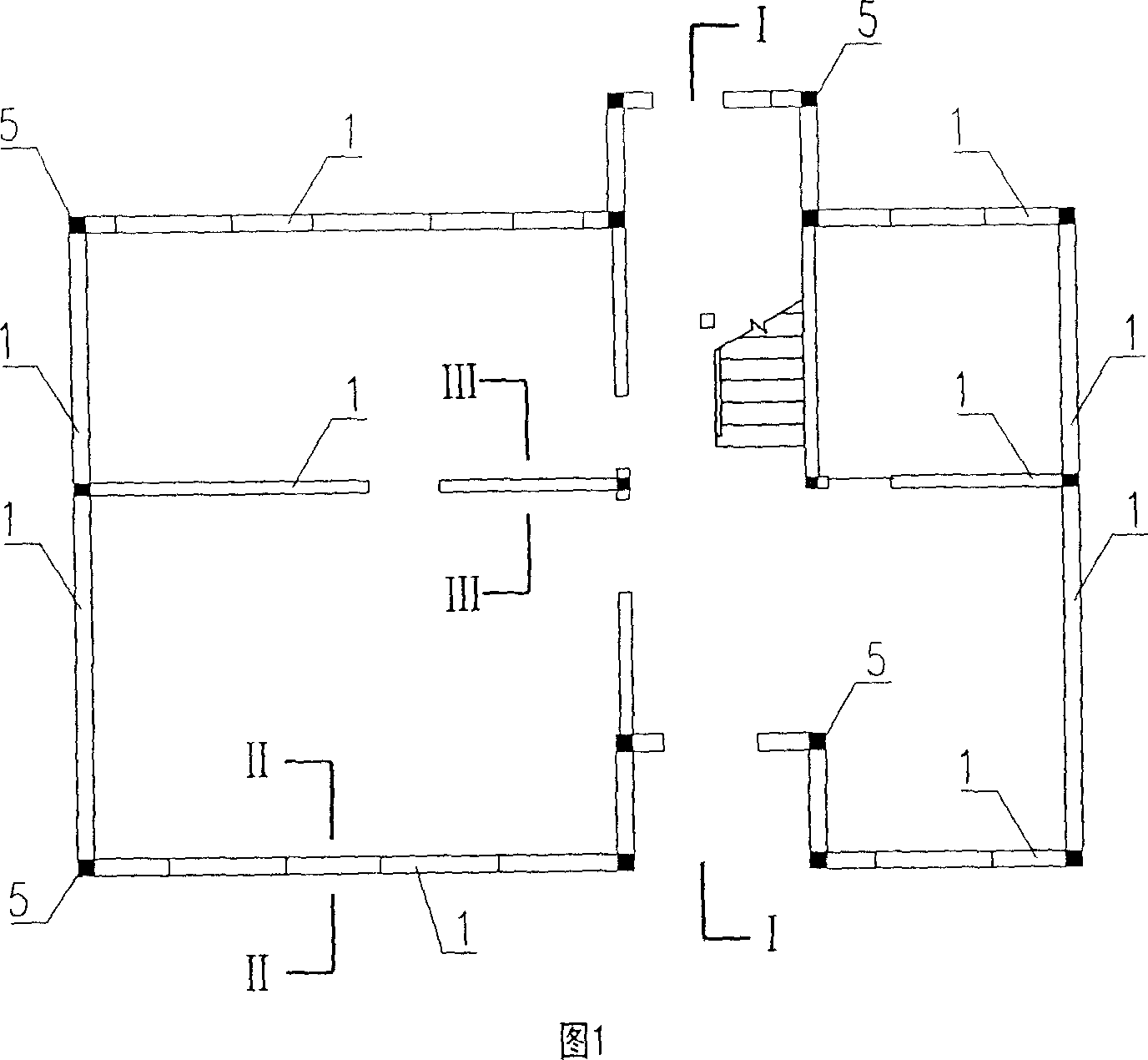

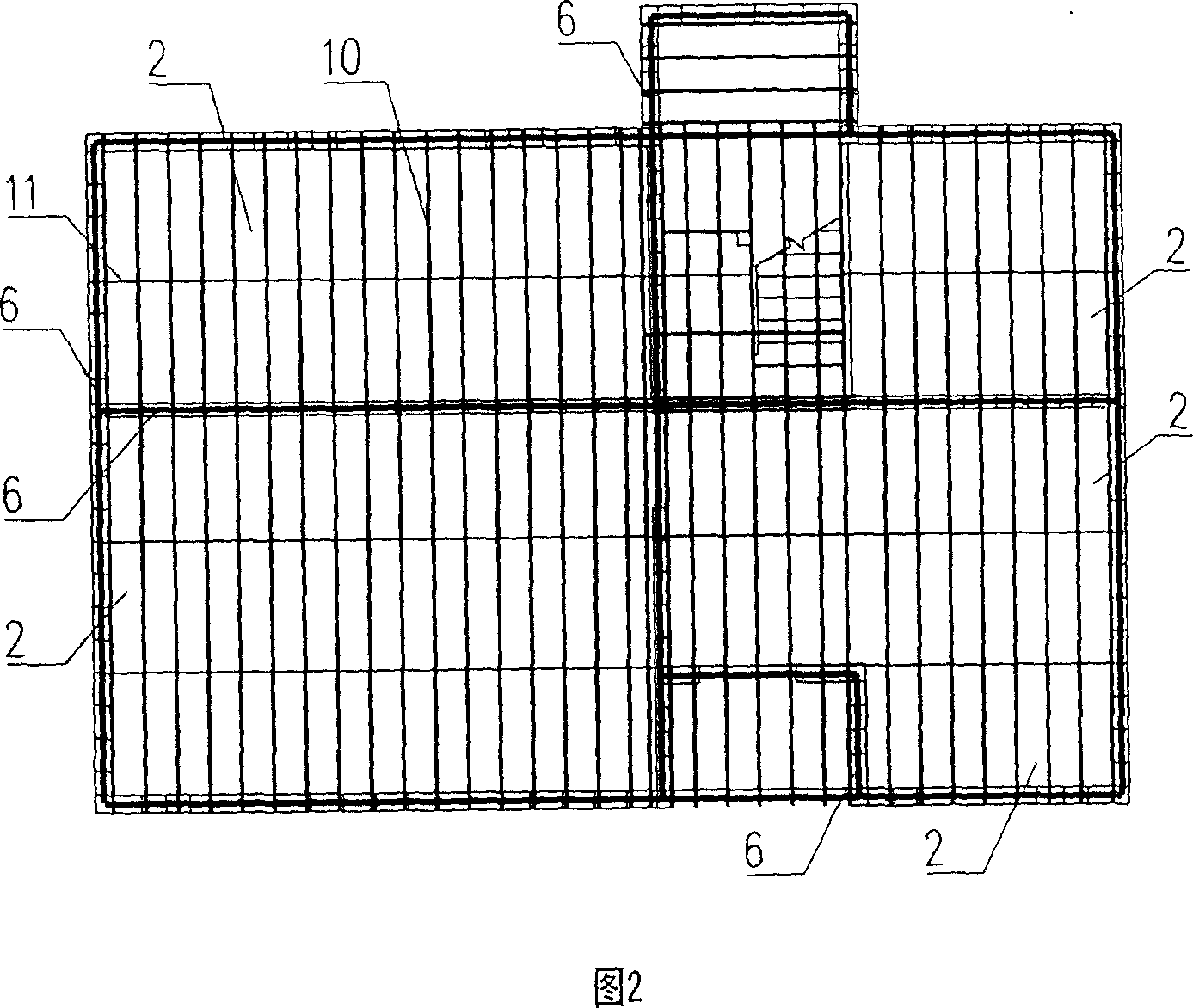

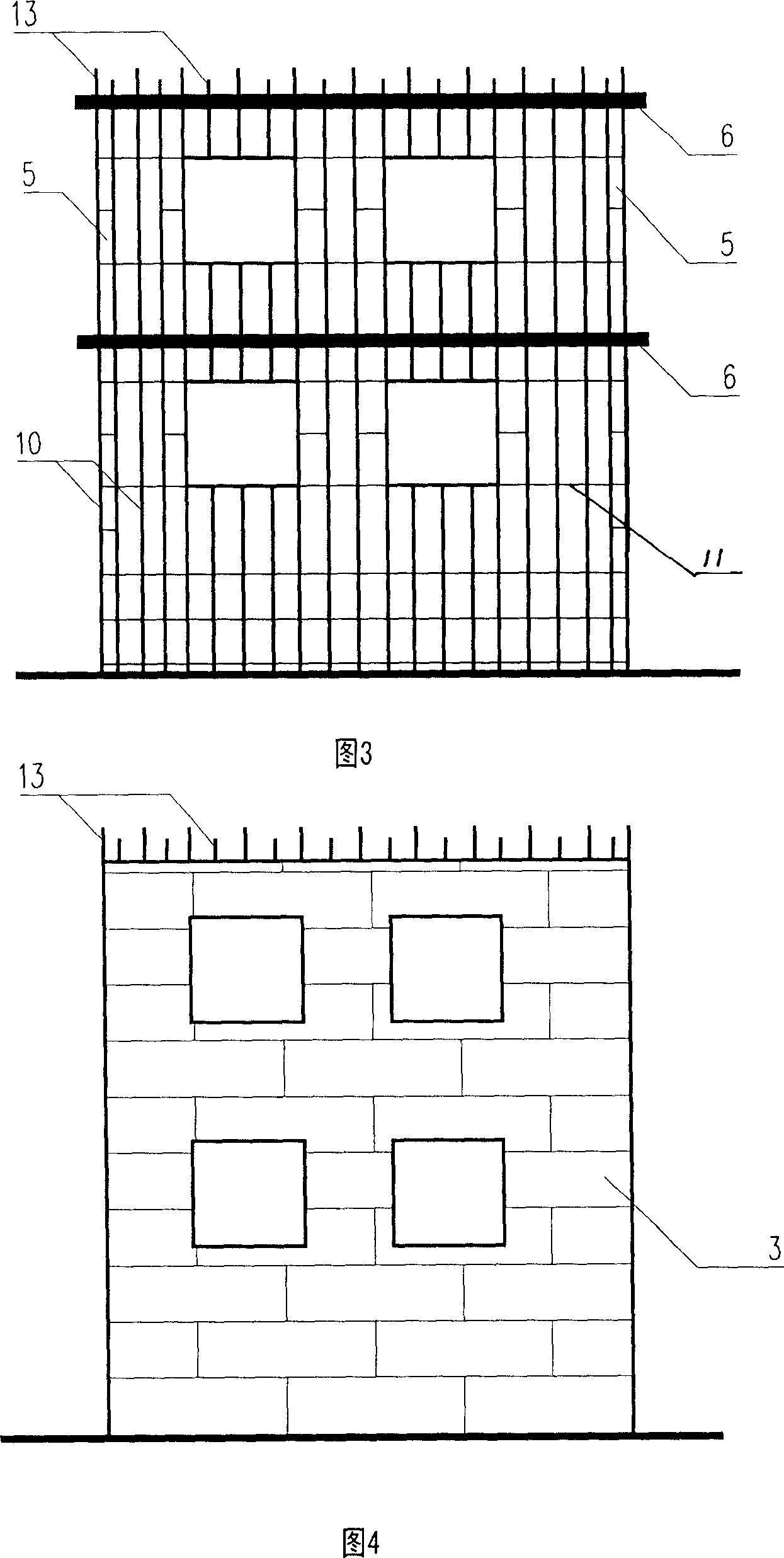

[0071] Shown in Fig. 1~Fig. 14 is the embodiment of the present invention, is a steel mesh frame concrete composite building with 4 floor slab structures. The composite building includes: wall steel skeleton 1, floor steel skeleton 2, steel mesh 3, and concrete 4:

[0072] As shown in Fig. 1, Fig. 3, Fig. 8, Fig. 9, and Fig. 11: the wall steel skeleton 1: is used for the composite building wall, and is arranged in parallel with each other by vertical lattice steel 10, and A steel skeleton formed by fixing with connectors 11;

[0073] As shown in Fig. 2, Fig. 8, Fig. 9 and Fig. 11: the floor steel skeleton 2: is used for the composite building floor, is arranged in parallel with each other by horizontal lattice steels 10, and is fixed by connectors 11 The formed steel skeleton, the floor steel skeleton 2 includes a roof steel skeleton;

[0074]Figure 5 shows a schematic diagram of lattice steel: lattice steel 10 is a cold-formed lattice steel member formed by cold-forming thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com