Apparatus for pressurizing gas, liquid

A gas-liquid pressurization and hydraulic cylinder technology, which is applied in fluid pressure converters, mechanical equipment, etc., can solve the problem of reducing oil flow and achieve stable work, no cost, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

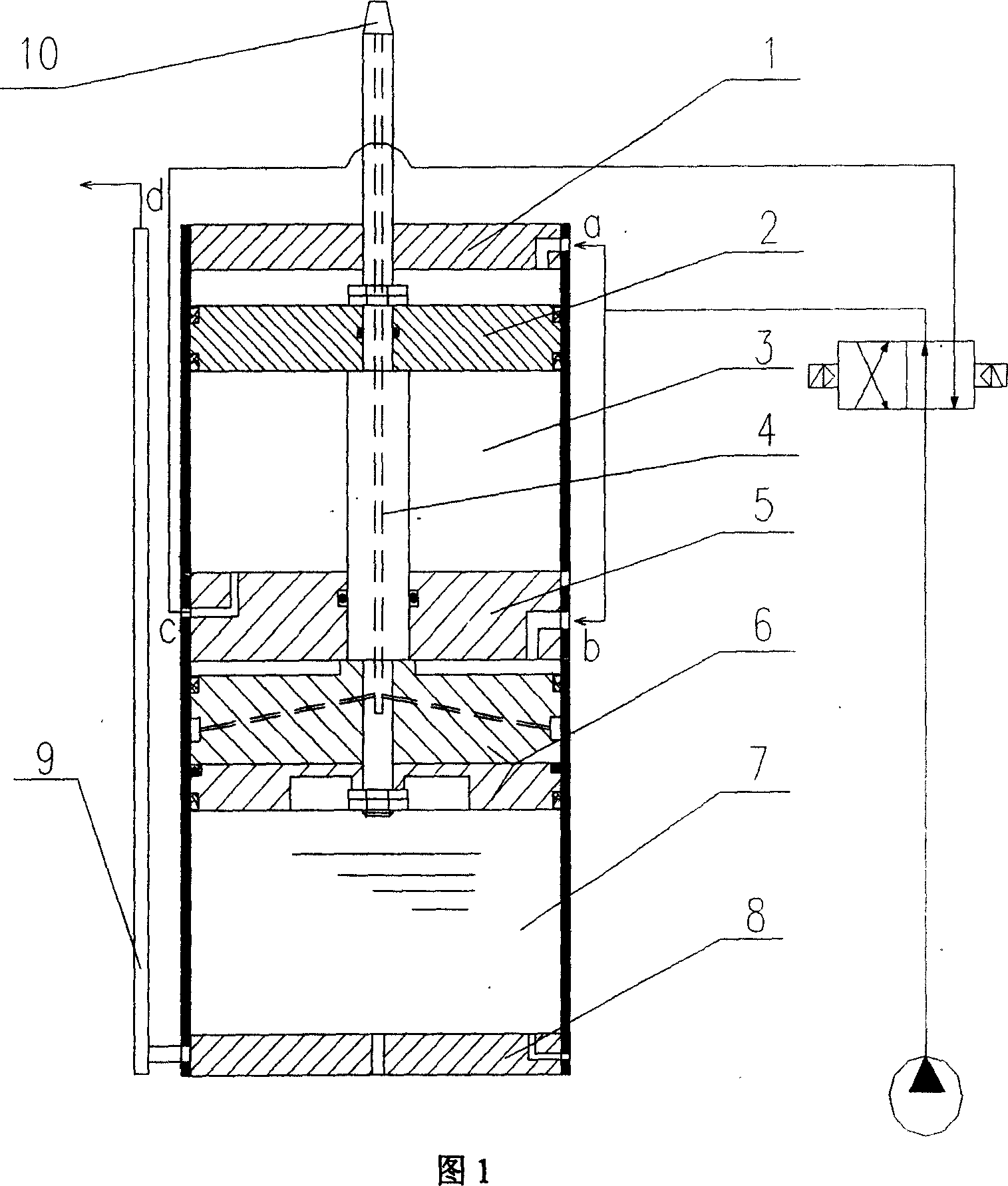

[0023] A gas-liquid supercharging device used in a hydraulic cylinder transmission system, which consists of a cylinder 7 and a piston 6, the piston 6 is set inside the cylinder 7, and a lower cylinder head 8 and a cylinder are respectively arranged at both ends of the cylinder 7 The cover 5, the cavity between the piston 6 and the lower cylinder cover 8 is an oil cavity, the cavity between the piston 6 and the cylinder cover 5 is an air cavity, and the lower cylinder cover 8 is provided with an oil outlet 9. The air inlet b of the air chamber is provided on the cover 5, which is characterized in that an upper cylinder 3 is provided on the cylinder head 5 and the cylinder head 5 is connected with one end of the upper cylinder 3, and the other end of the upper cylinder 3 There is an upper cylinder head 1, a cylinder piston 2 is arranged in the upper cylinder 3, an air inlet a is arranged on the upper cylinder head 1, and a breathing hole c which can communicate with the upper cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com