Method and device for testing oxide of grid electrode by using fuse wire

A fuse and bias technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., to achieve rapid detection, improve detection reliability, and improve detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention relates generally to integrated circuits. More specifically, the present invention provides a method and apparatus for testing an oxide layer using a fuse. Merely by way of example, the invention has been applied to testing gate oxide layers. It should be recognized, however, that the invention has broader applicability.

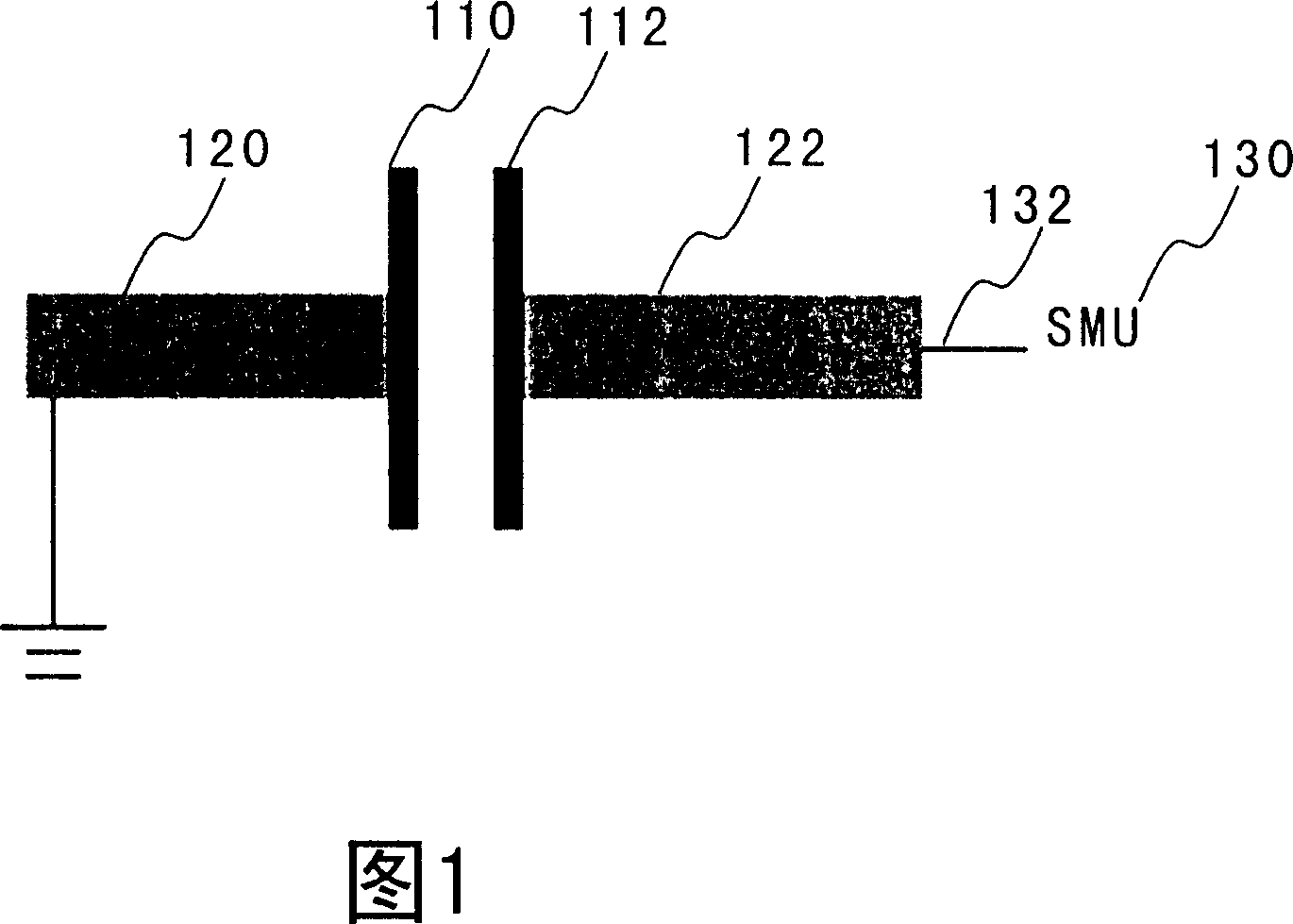

[0017] As mentioned above, in FIG. 1, when the gate oxide layer breaks down, the current flowing through the wire 122 will become very high. High currents can burn the metal wires 122 and / or damage the probe card 132 . If the metal wire 122 is burned out, the metal wire 122 is disconnected, and the current flowing through the metal wire decreases rapidly. Therefore, breakdown of the gate oxide layer can become difficult to detect.

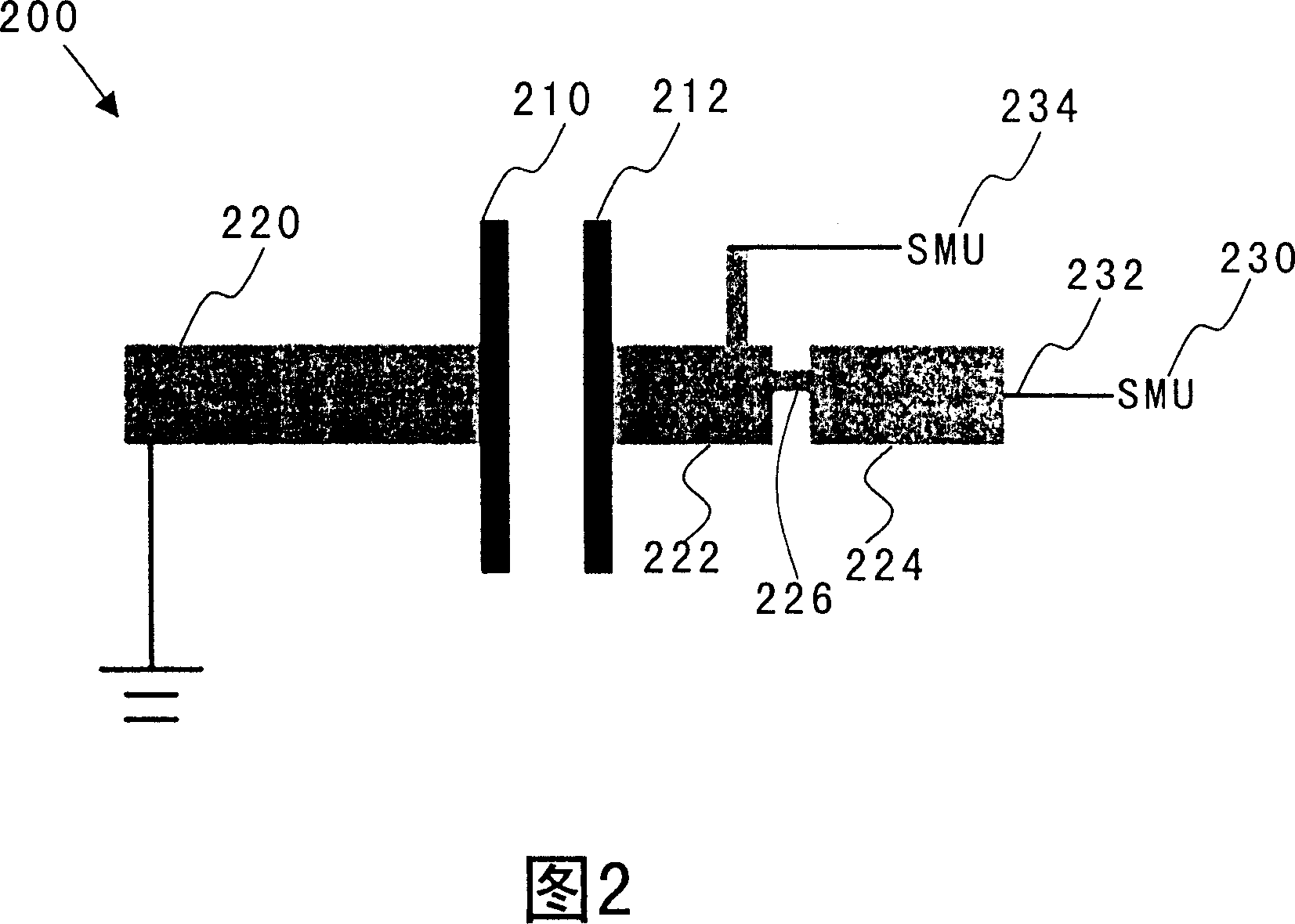

[0018] FIG. 2 is a simplified setup for testing a gate oxide layer according to an embodiment of the present invention. This diagram is merely an example, which should not unduly limit the scope ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com