Method for manufacturing ceramic cleaning tool model and ceramic cleaning tool model manufactured therefrom

A new method, model of technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

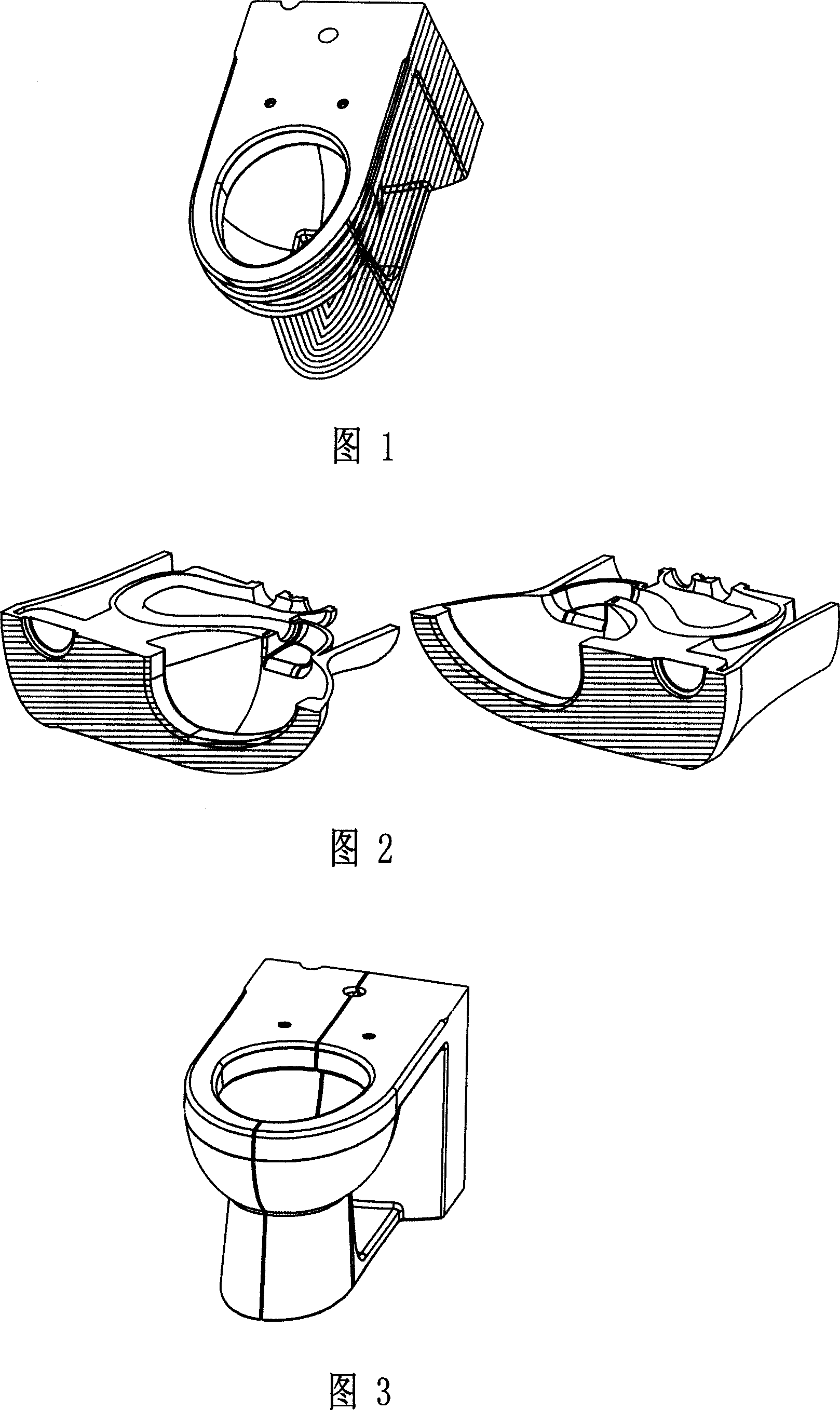

[0011] Taking the toilet model shown in Figure 1 as an example, the production process includes the following steps:

[0012] Input the modeling data of the toilet model into the computer to obtain a three-dimensional digital model, and the computer will layer the three-dimensional digital model according to the layering path shown in Figure 1 according to a certain layer thickness, and obtain the two-dimensional graphics of the section of each layer (indicated by Clearly, the thickness of each layer is exaggerated in Figure 1), when forming, the sand grains are spread and stacked layer by layer on the equipment working platform under the control of the moldless sand mold manufacturing equipment, and the sand grains laid on each layer are bonded agent, so that all the sand grains within the range of the two-dimensional graphics entity are bonded into a three-dimensional entity, and the unbonded sand grains are removed to obtain a sand mold. The above steps are the same as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com