Forced guiding mechanism of independent wheel pair two-axle bogie articulated car

A bogie and forced-guide technology, applied in the field of forced-guide mechanisms, can solve the problems of impossible simultaneous tending and forced-guided bogie guiding ability defects, and achieve the effects of easy fabrication, simple structure and improved safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

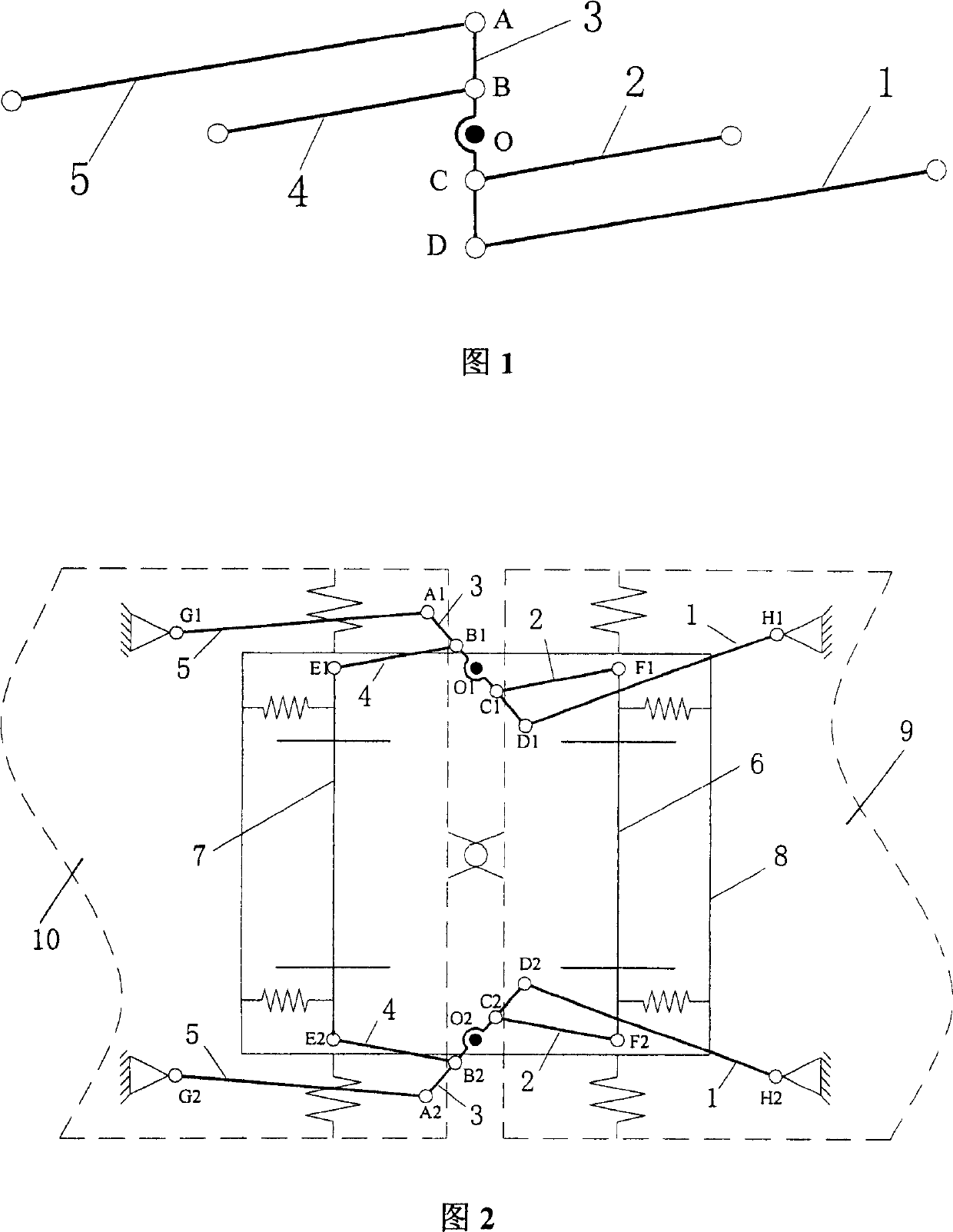

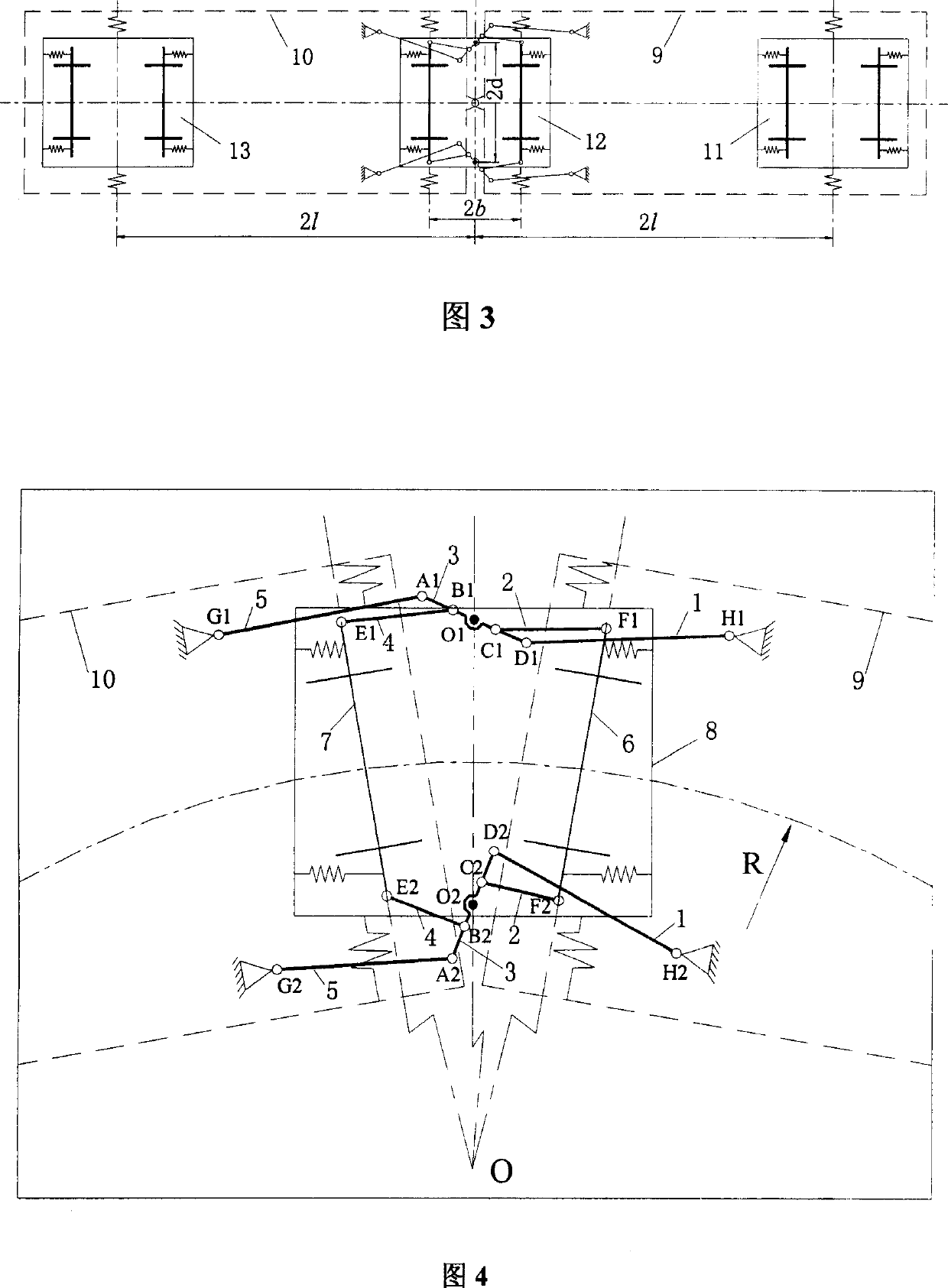

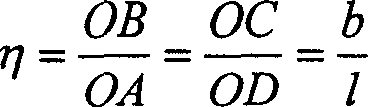

[0019] The structure of the independent wheel pair two-axle bogie articulated car force guide mechanism in this embodiment is shown in Figure 1, which consists of a guide arm 3, a front car body link 1, a front wheel pair link 2, and a rear car body link 5. And rear wheel is formed to connecting rod 4. Let the midpoint of the guide arm 3 be O, the hinge point D between the front body connecting rod 1 and the guide arm 3, the hinge point C between the front wheel pair connecting rod 2 and the guide arm 3 are located on the side of the guide arm midpoint O, and the rear The hinge point B of the wheel set connecting rod 4 and the guide arm 3, the hinge point A of the rear vehicle body link 5 and the guide arm 3 are located on the other side of the guide arm midpoint. Guide arm length AD > 2 l · d R , Front body link 1. The hinge points of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com