Energy utilization and recovery type cell full air air-condition set

An air-conditioning unit and unit technology, which is applied in the energy recovery system of ventilation and heating, shielding with air flow, air-conditioning system, etc. The effect of flexible settings and reduced requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

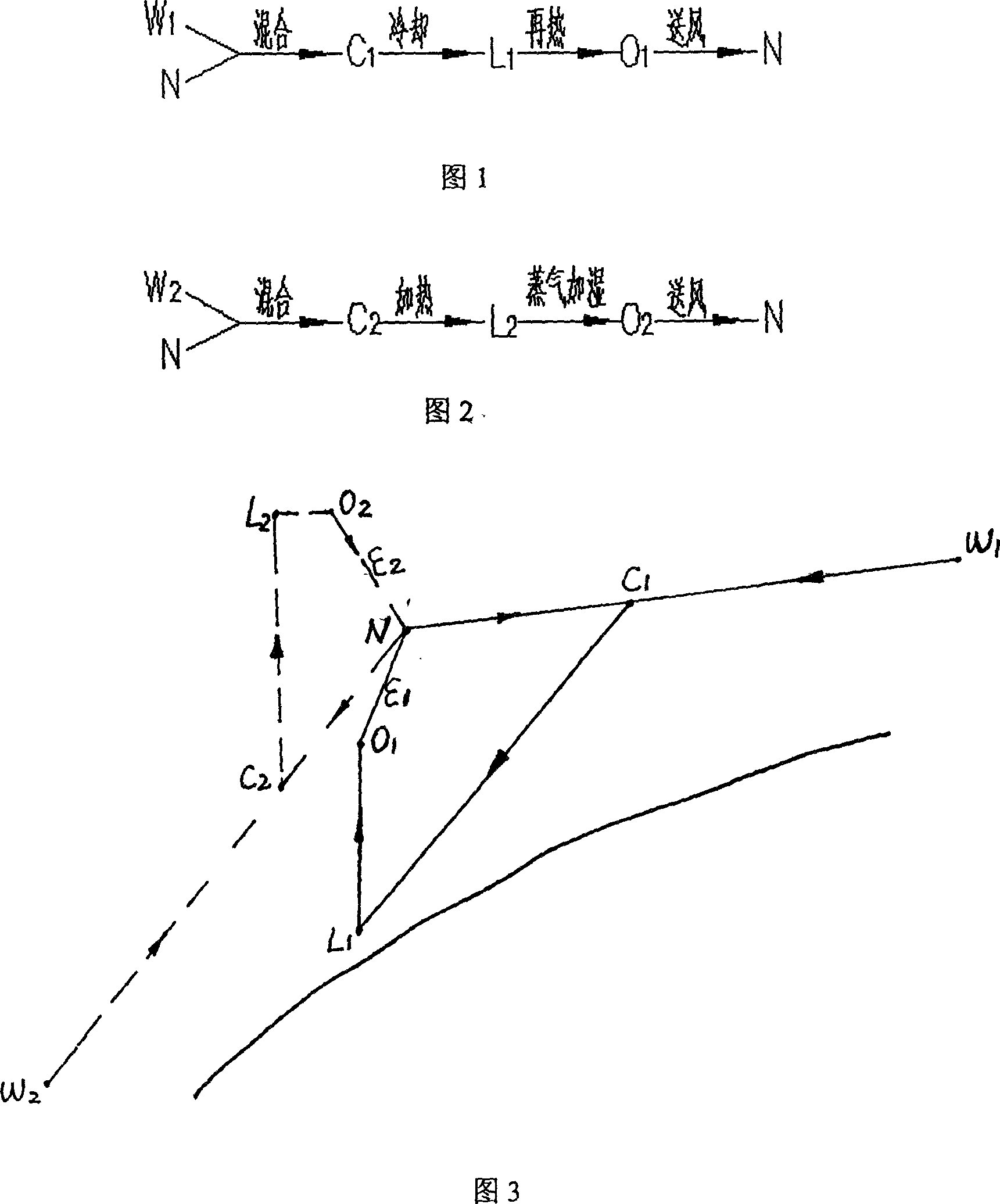

[0045] Embodiment 1, is used for the process air conditioner that clean (or aseptic) requirement is arranged

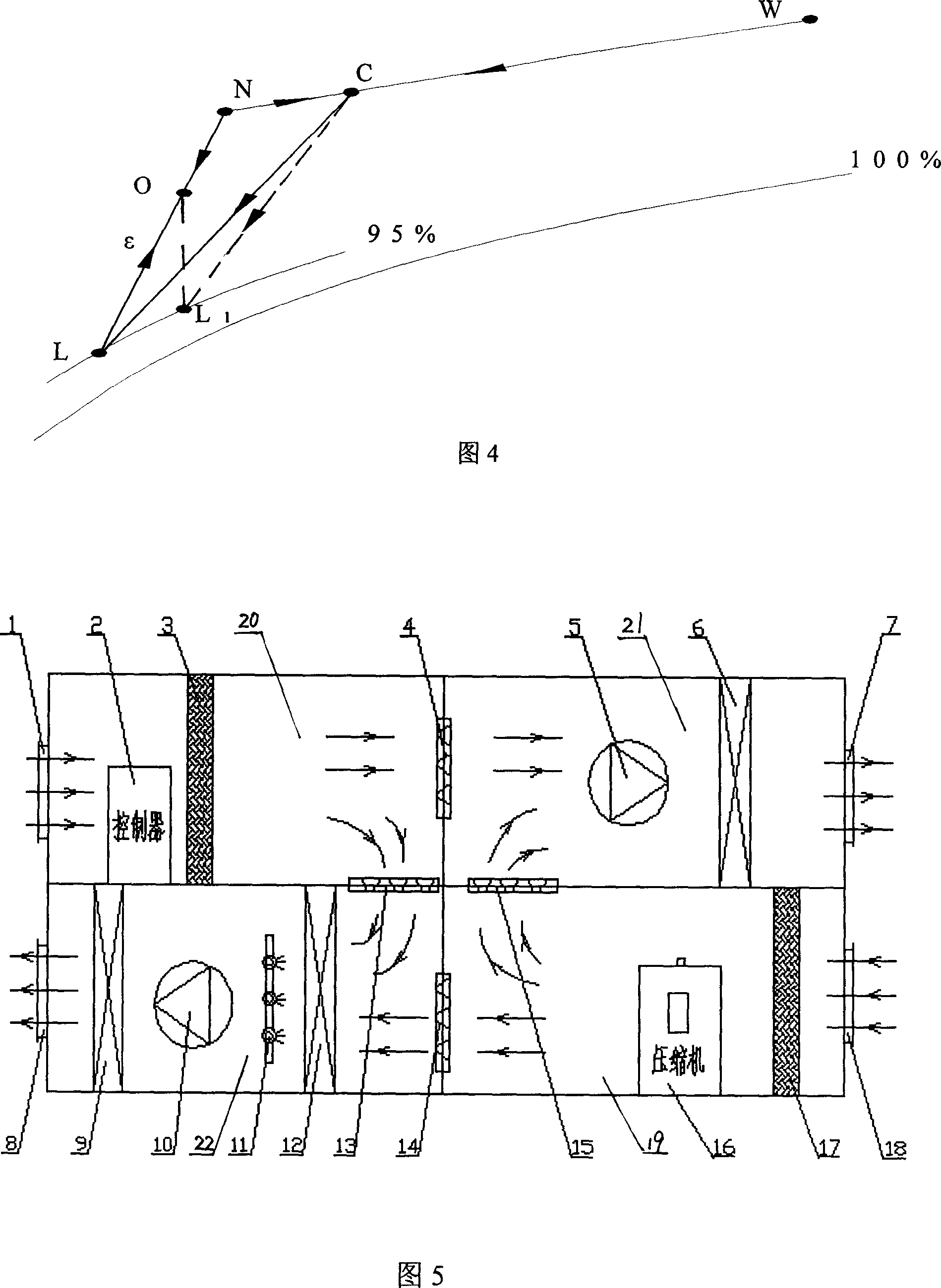

[0046] The unit of the present invention is made up of four casings of return air box 20, exhaust air box 21, air supply box 22 and fresh air box 19, is provided with exhaust valve 4 between return air box 20 and exhaust air box 21, and return air box 20 and air supply A return air valve 13 is provided between the boxes 22, a fresh air valve 14 is provided between the air supply box 22 and the fresh air box 19, and a bypass valve 15 is provided between the fresh air box 19 and the exhaust box 21. The return air box 20 is composed of the return air outlet 1, the controller 2 and the return air filter 3, the return air outlet 1 is located on the side of the return air box 20, the controller 2 is located at the return air outlet 1, and the return air filter 3 is connected to the controller 2; Box 21 is made up of exhaust fan 5, exhaust air condenser 6 and exhaust outlet ...

Embodiment 2

[0048] Example 2, used in places with constant temperature and humidity control requirements

[0049] The unit of the present invention is made up of four casings of return air box 20, exhaust air box 21, air supply box 22 and fresh air box 19, is provided with exhaust valve 4 between return air box 20 and exhaust air box 21, and return air box 20 and air supply A return air valve 13 is provided between the boxes 22, a fresh air valve 14 is provided between the air supply box 22 and the fresh air box 19, and a bypass valve 15 is provided between the fresh air box 19 and the exhaust box 21. Return air box 20 is composed of return air outlet 1, controller 2 and return air filter 3, or additional purification device, return air outlet 1 is located on the side of return air box 20, controller 2 is located at return air outlet 1, and return air filter 3 is connected and controlled Device 2; Exhaust air box 21 is made up of exhaust fan 5, exhaust air condenser 6 and air outlet 7, an...

Embodiment 3

[0051] Example 3, a large space with year-round air conditioning requirements

[0052] The unit of the present invention is made up of four casings of return air box 20, exhaust air box 21, air supply box 22 and fresh air box 19, is provided with exhaust valve 4 between return air box 20 and exhaust air box 21, and return air box 20 and air supply A return air valve 13 is provided between the boxes 22, a fresh air valve 14 is provided between the air supply box 22 and the fresh air box 19, and a bypass valve 15 is provided between the fresh air box 19 and the exhaust box 21. The return air box 20 is composed of the return air outlet 1, the controller 2 and the return air filter 3. The return air outlet 1 is located on the side of the return air box 20, the controller 2 is located at the return air outlet 1, and the return air filter 3 is connected to the controller 2; Bellows 21 is made up of exhaust fan 5, exhaust air condenser 6 and air outlet 7, and exhaust air outlet 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com