Automatic wetting and drying cycle apparatus for corrosion test sample

A corrosion test, dry-wet cycle technology, used in measuring devices, weather resistance/light resistance/corrosion resistance, laboratory utensils, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

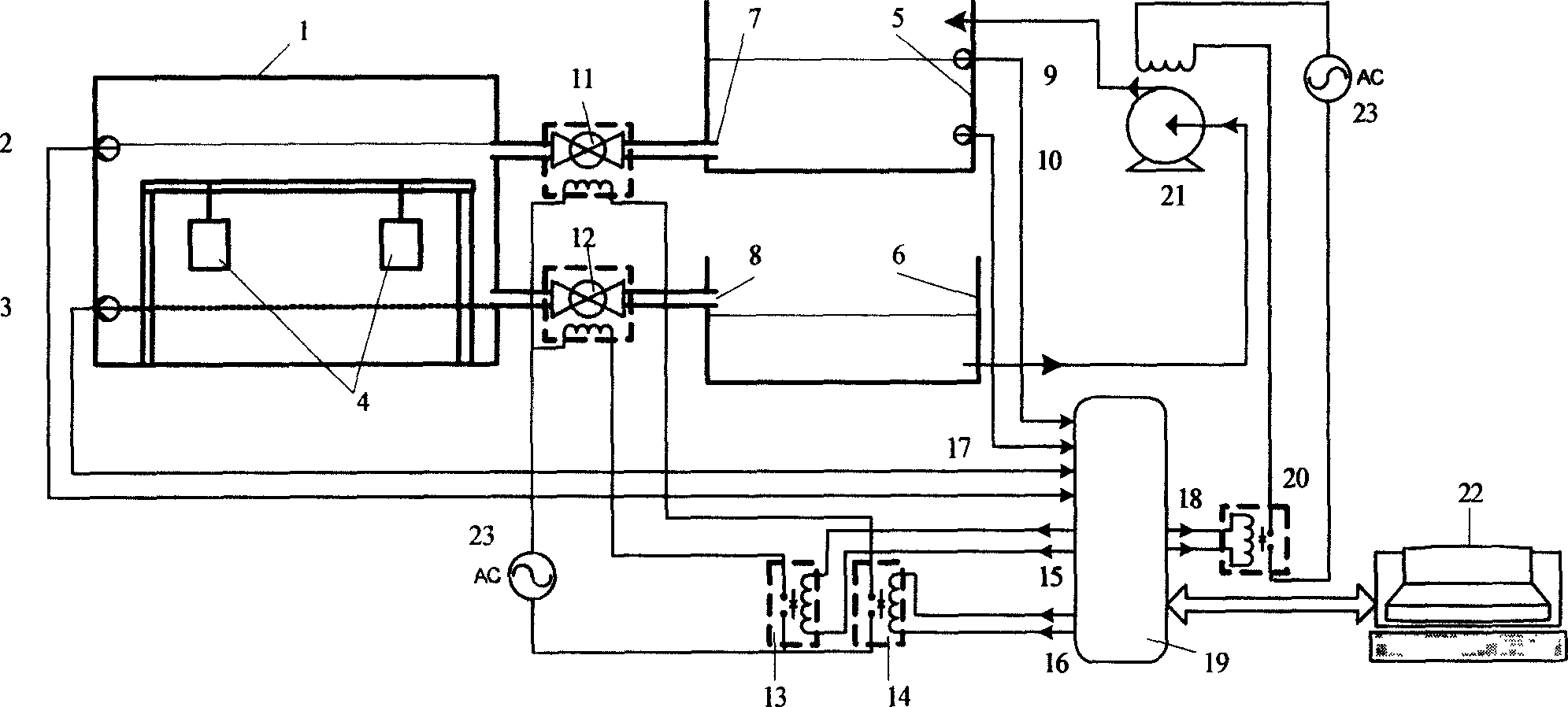

[0007] The feature of the corrosion test sample automatic dry-wet cycle device of the present invention is that the water inlet of its corrosion test water tank 1 communicates with the water outlet pipe 7 at the bottom of the high water tank 5 through the water inlet solenoid valve 11, and the water inlet solenoid valve 11 passes through the water inlet control relay 14 is connected to the numerical output terminal 16 of the data acquisition control board 19; the drain port of the corrosion test tank 1 is communicated with the upper water inlet pipe 8 of the lower tank 6 through the drain solenoid valve 12, and the drain solenoid valve 12 is connected with the data acquisition control through the control relay 13 The numerical output terminal 15 of plate 19 is connected; the high-level liquid level sensor 2 and the low-level liquid level sensor 3 of the corrosion test water tank 1 are respectively connected with two input channels in the data input terminal 17 of the data acquis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com