Gas sensor

A gas sensor and sensing element technology, applied in instruments, scientific instruments, measuring devices, etc., can solve problems such as easy collision, unstable structure of the atmosphere-side insulator 95, and damage to the electrode terminals of the sensing element, etc., and achieve a lightweight structure , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

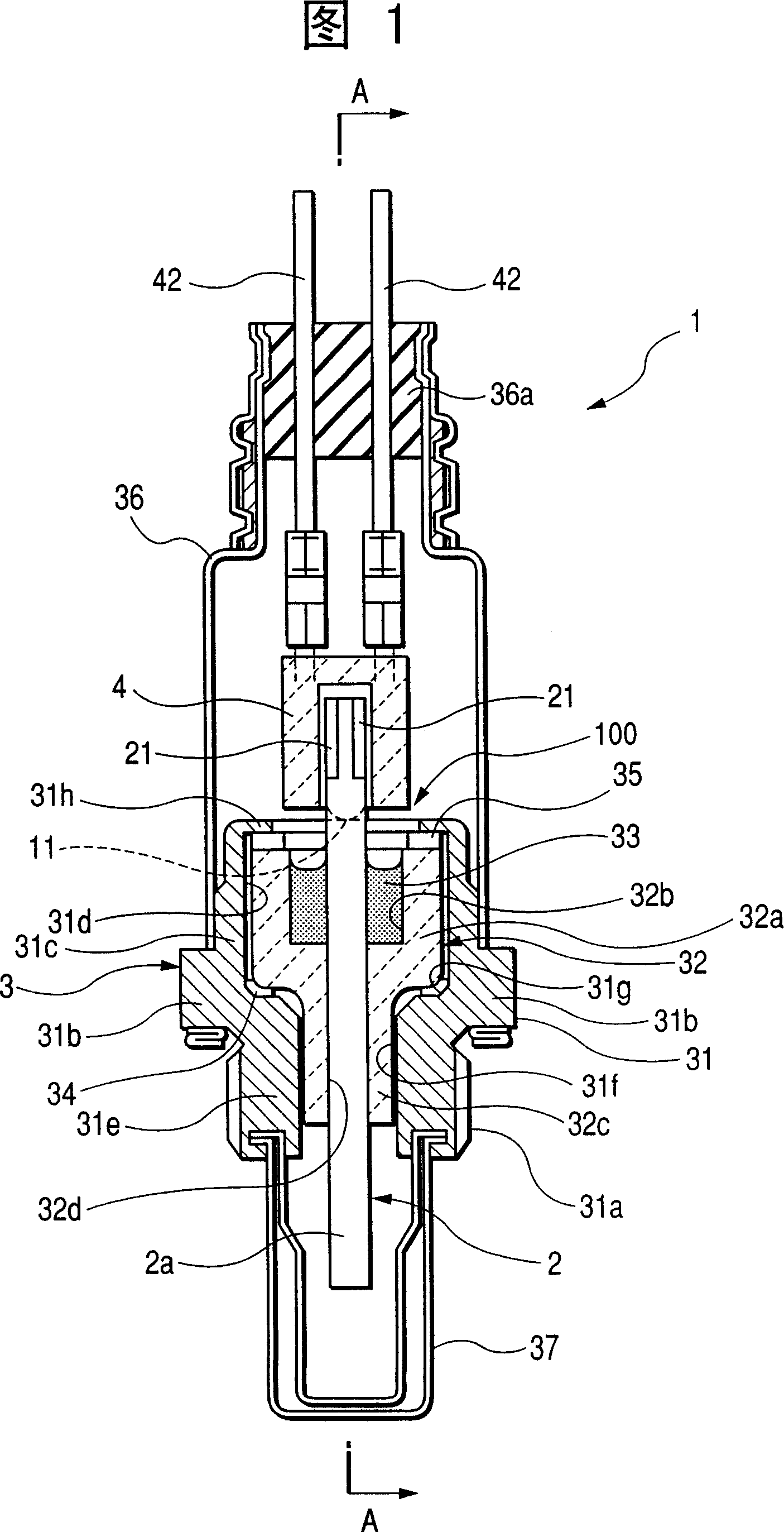

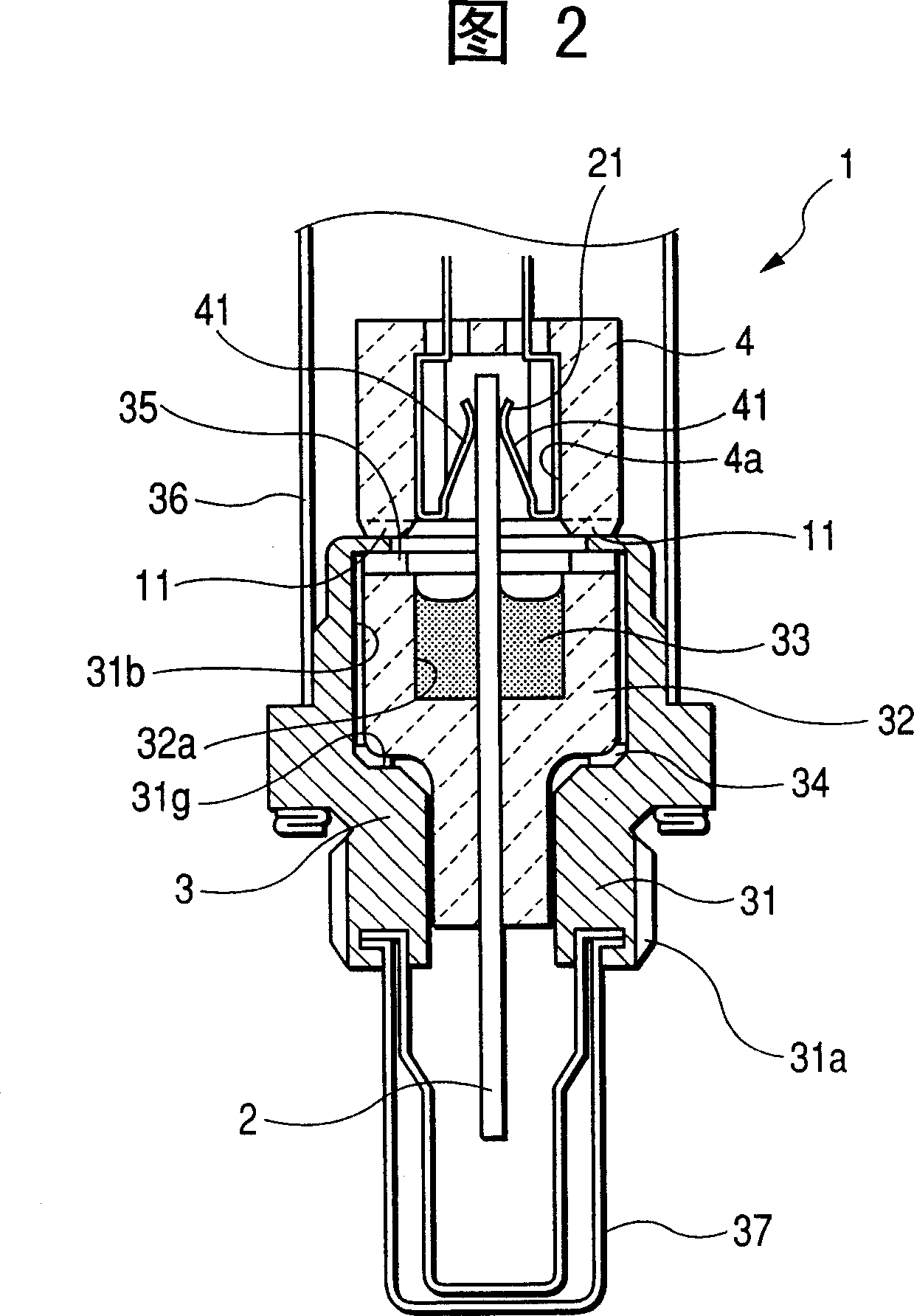

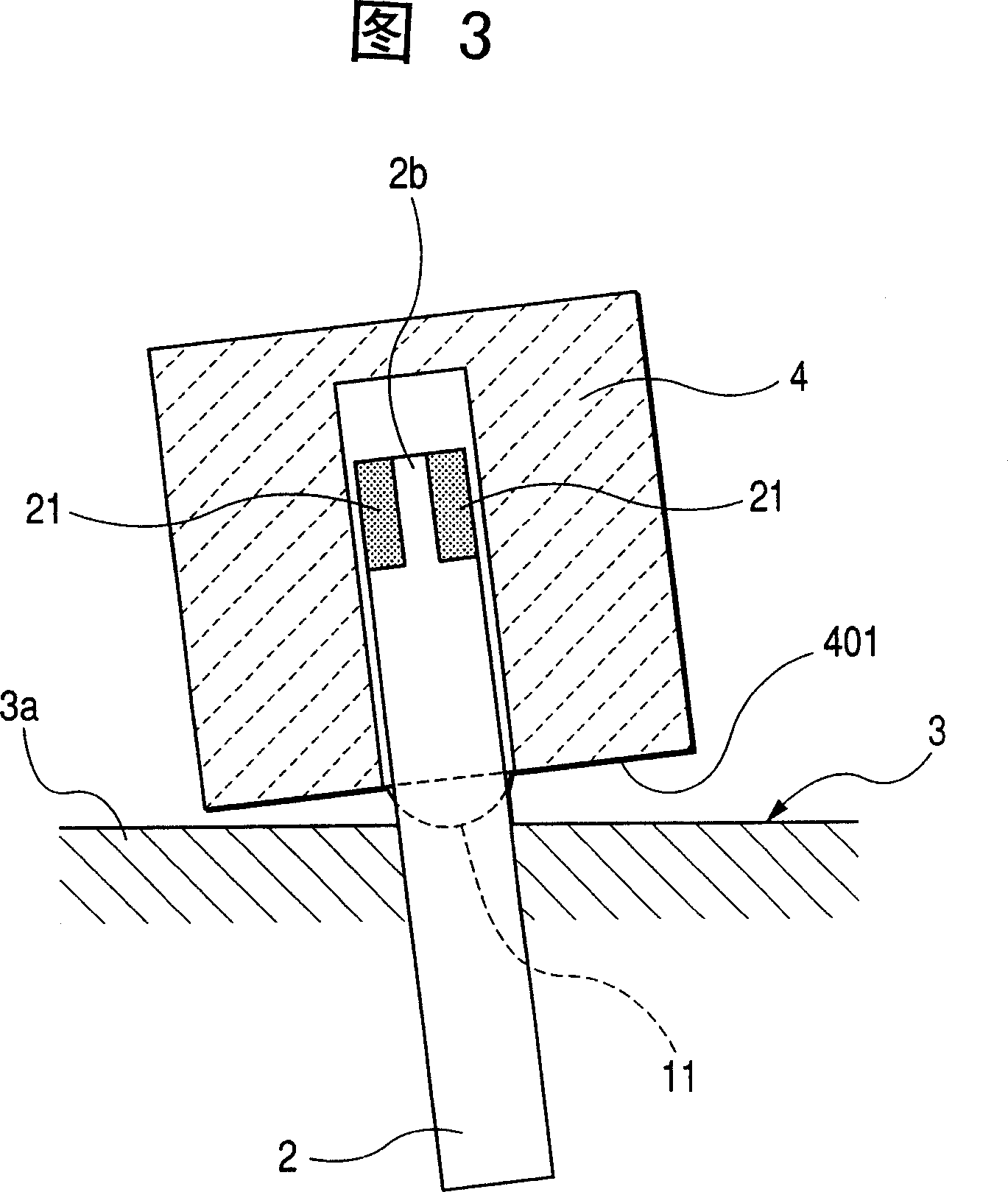

[0050] A gas sensor according to a first embodiment of the present invention will be described in detail with reference to FIGS. 1-6.

[0051] As shown in FIGS. 1 and 2, the gas sensor 1 of the present invention includes a sensing element 2 having a rectangular cross section, which has a detection portion for detecting the concentration of a specific gas in the gas to be measured (hereinafter referred to as the measurement gas). 2a and a base end portion 2b, an element holder 3 for inserting and holding the sensor element 2, and an atmosphere side insulator 4 provided at a position so as to cover the sensor in an area close to the base end of the element holder 3. base of sensing element 2.

[0052] The element holder 3 includes a housing 31 formed with a threaded portion 31a which can be screwed into the flow channel region of the measurement gas to allow the sensing element 2 to detect the measurement gas; An element-side insulator 32 inside the housing 31 . The sensor ele...

no. 2 example

[0073] Next, a gas sensor 1A according to a second embodiment of the present invention will be described with reference to FIGS. 7 and 8 . Except for some features, the gas sensor of the second embodiment is similar in structure to the gas sensor of the first embodiment, and redundant descriptions will be omitted to focus on these distinguishing features.

[0074] 7 is a sectional view of a gas sensor 1A of a second embodiment, and FIG. 8 is a sectional view of a gas sensor 1A showing a structure in which a projecting portion 11A is formed at a base end of an element holder 3A.

[0075] With the gas sensor 1A of the second embodiment, an element holder insulator 32A forming the element holder 3 has a cylindrical body 32a whose base end protrudes beyond a base end, that is, to a fitting portion 31h of the housing 31A. outside. Also, the cylindrical body 32a has a large-diameter portion 321 formed between the first and second cylindrical portions 32a and 32c, which is accommoda...

no. 3 example

[0079] Next, a gas sensor 1B according to a third embodiment of the present invention will be described with reference to FIGS. 9 to 11 . Except for some features, the gas sensor 1B of the third embodiment is similar in structure to the gas sensor 1 of the first embodiment, and redundant descriptions will be omitted to focus on these distinguishing features.

[0080] 9 is a cross-sectional view of the gas sensor 1B of the third embodiment, and FIG. 10 is a cross-sectional view of the gas sensor 1B along line C-C of FIG. FIG. 11 is a cross-sectional view of the gas sensor 1B along line D-D in FIG. 10 .

[0081] As for the third embodiment, the gas sensor 1B includes an inner protective cylinder 361 coaxially arranged at the base end of the atmosphere side cover 36 and supported by the base end of the housing 31B, which has a shape fixed by the outer circumference of the first cylindrical extension 31c. One base end supported on the ground and the other base end portion 362 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com