Tea frying machine

The technology of a tea frying machine and a frying pan is applied in the direction of tea treatment before extraction, etc., which can solve the problems of poor smoke exhaust, long tea making time, waste of energy and resources, etc., and achieves beautiful appearance, improves energy utilization rate, and maintains flavor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

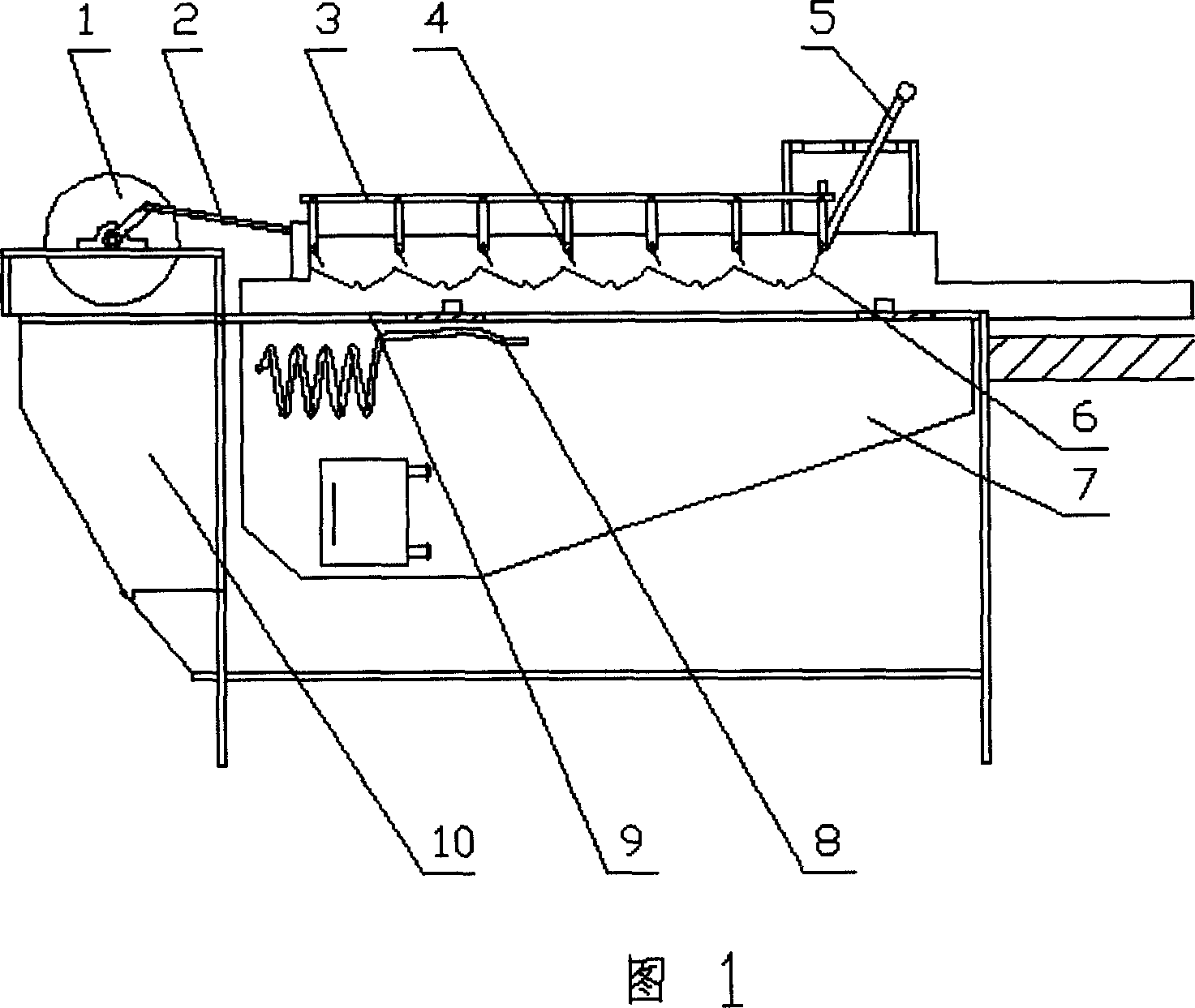

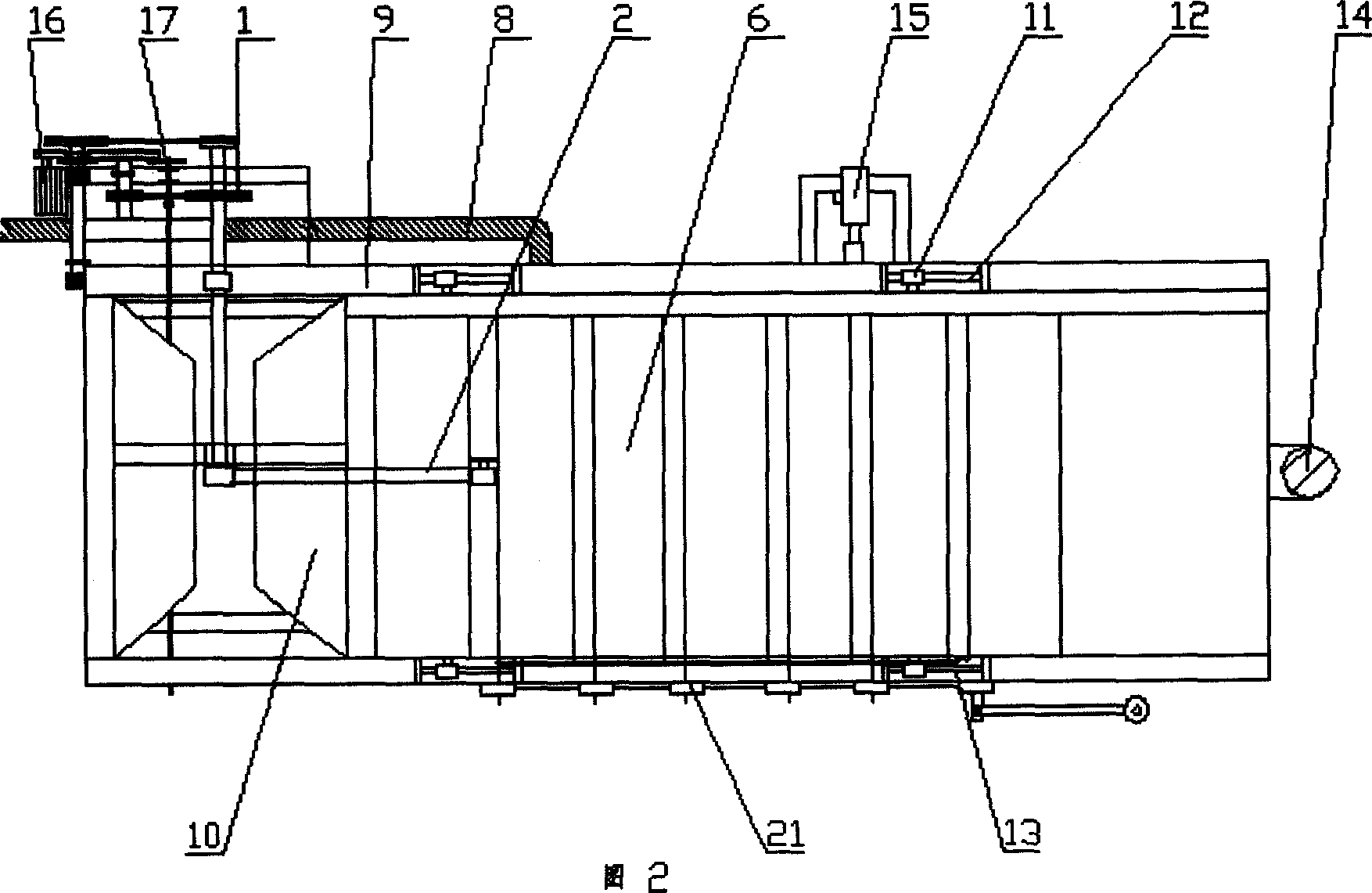

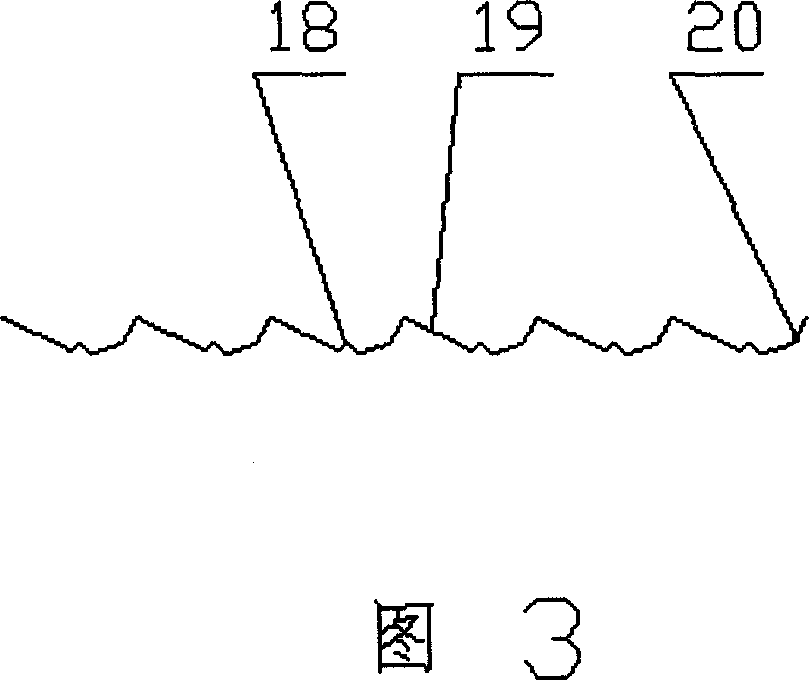

[0014] Combining Fig. 1, Fig. 2 and Fig. 3, a tea frying machine is mainly composed of a motor 16, a speed reduction mechanism 17, a frame 9, a frying pan 6, a tea bucket 10 and a stove 7, and the frying pan 8 is a group of long grooved pots , the bottom of each trough-shaped pot has a convex edge along the groove direction, and the frying pan 6 is fixed on a rectangular frame, which is provided with a crank connecting rod 2 connected with the reduction mechanism 2, and the frame passes through the sliding sleeve 11. The polished rod 12 is installed on the frame 9. In order to maintain good lubrication between the sliding sleeve 11 and the polished rod 12, they are installed in the oil groove 13 provided on the frame 9 to reduce the noise generated during work. Stove 7 is positioned at the bottom of frame 9, is provided with flue 14. One end of the long trough-shaped pot rib 18 designed in the embodiment of the present invention is a slope-shaped surface 19, and the other end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com