Method for preparing biomimetic super hydrophobic surface

A super-hydrophobic, ionized water technology, applied in the direction of metal material coating process, can solve the problems of high cost, unsuitable for industrial production, complex process, etc., to prevent corrosion, good heat resistance and acid and alkali corrosion resistance, Prepare industrially simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Use an ultrasonic cleaner to clean the aluminum and its alloy samples. The cleaning steps are: 1) put the aluminum and its alloy samples in acetone and clean them ultrasonically for 30 minutes to remove the grease on the samples; Put the good sample into 5wt% HCl solution for 10min to remove the oxide layer on the sample, 3) then wash it with deionized water for 5min, 4) finally dry it in a vacuum oven at 50°C for 30min before use;

[0027] 2. Put the treated aluminum and its alloy samples into 1M NaOH solution for oxidation for 2 hours; the oxidized aluminum and its alloy samples are washed with deionized water to remove excess NaOH solution on the surface of the oxidized sample, and then Dry the oxidized sample in the atmosphere at 120°C for 1h;

[0028] 3. Add perfluorononane dropwise to the surface of the dried sample for chemical modification, and then dry it with a hair dryer to obtain a bionic superhydrophobic surface.

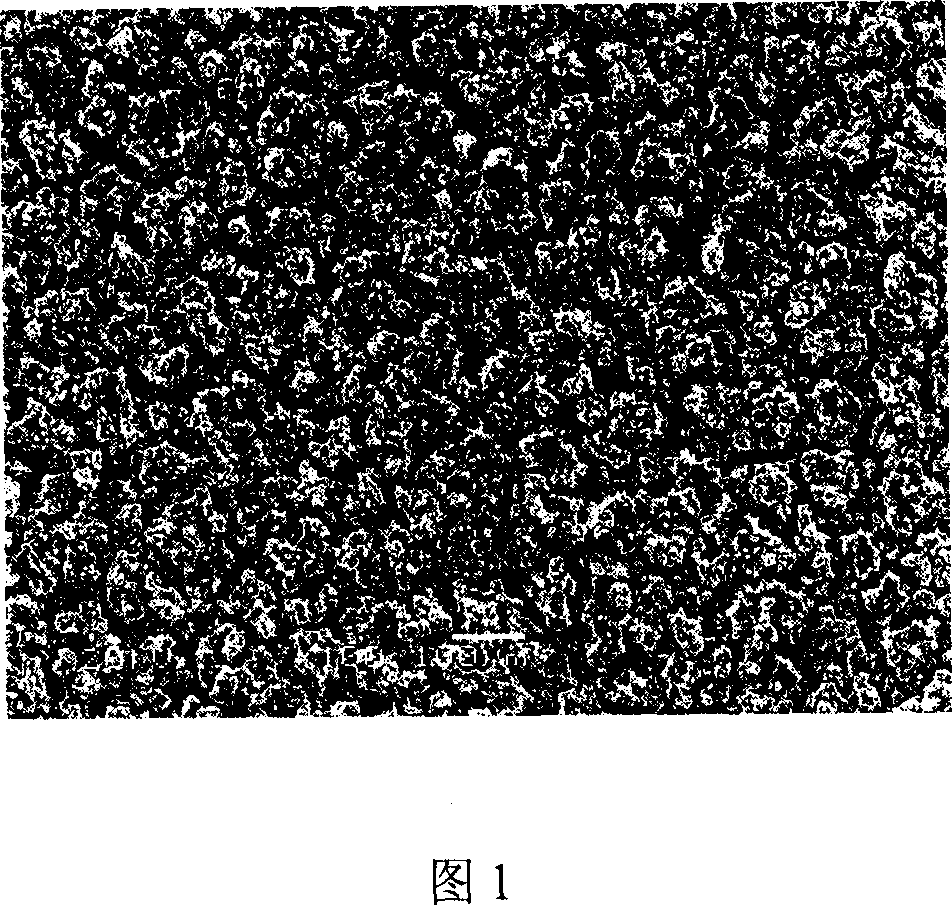

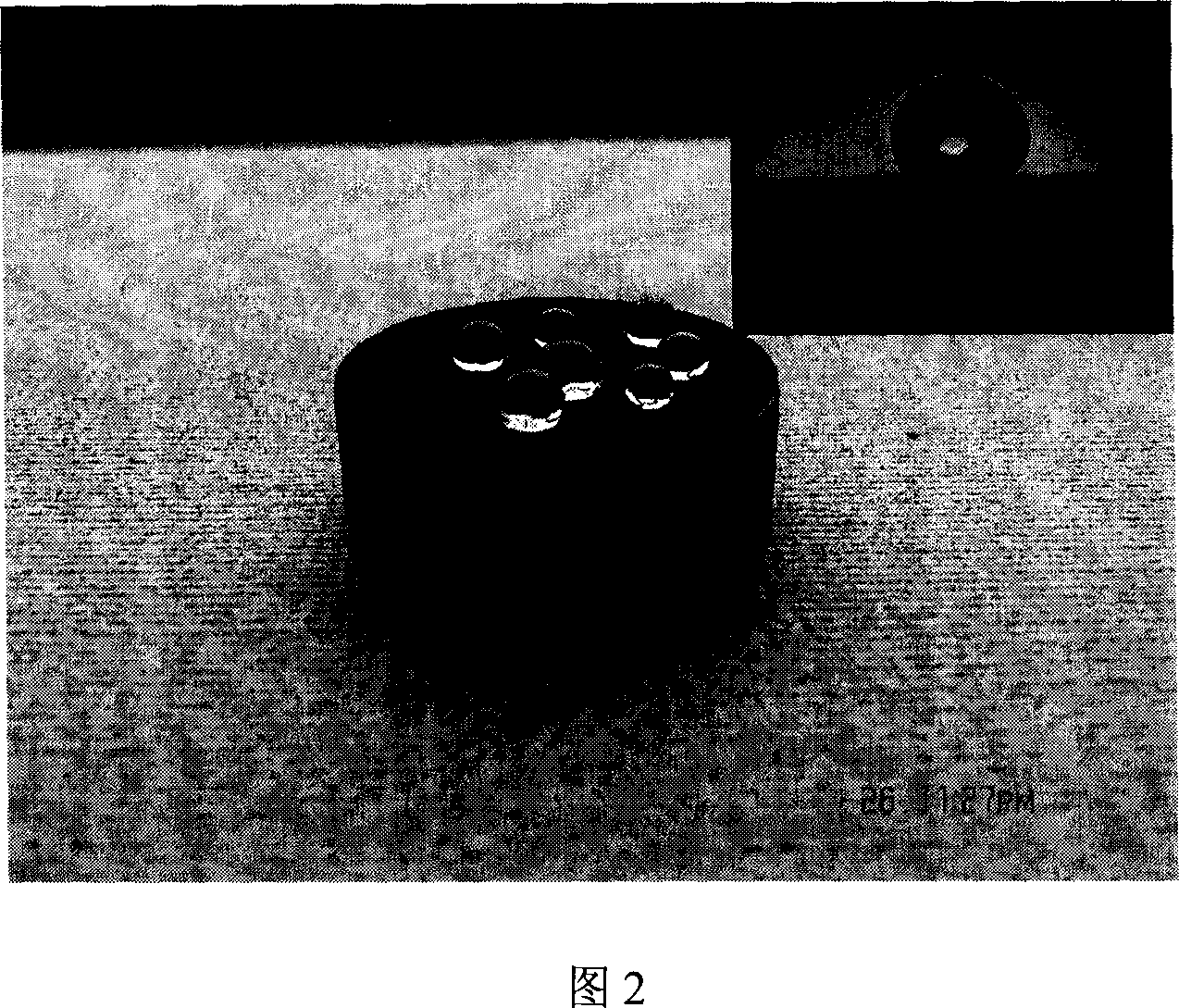

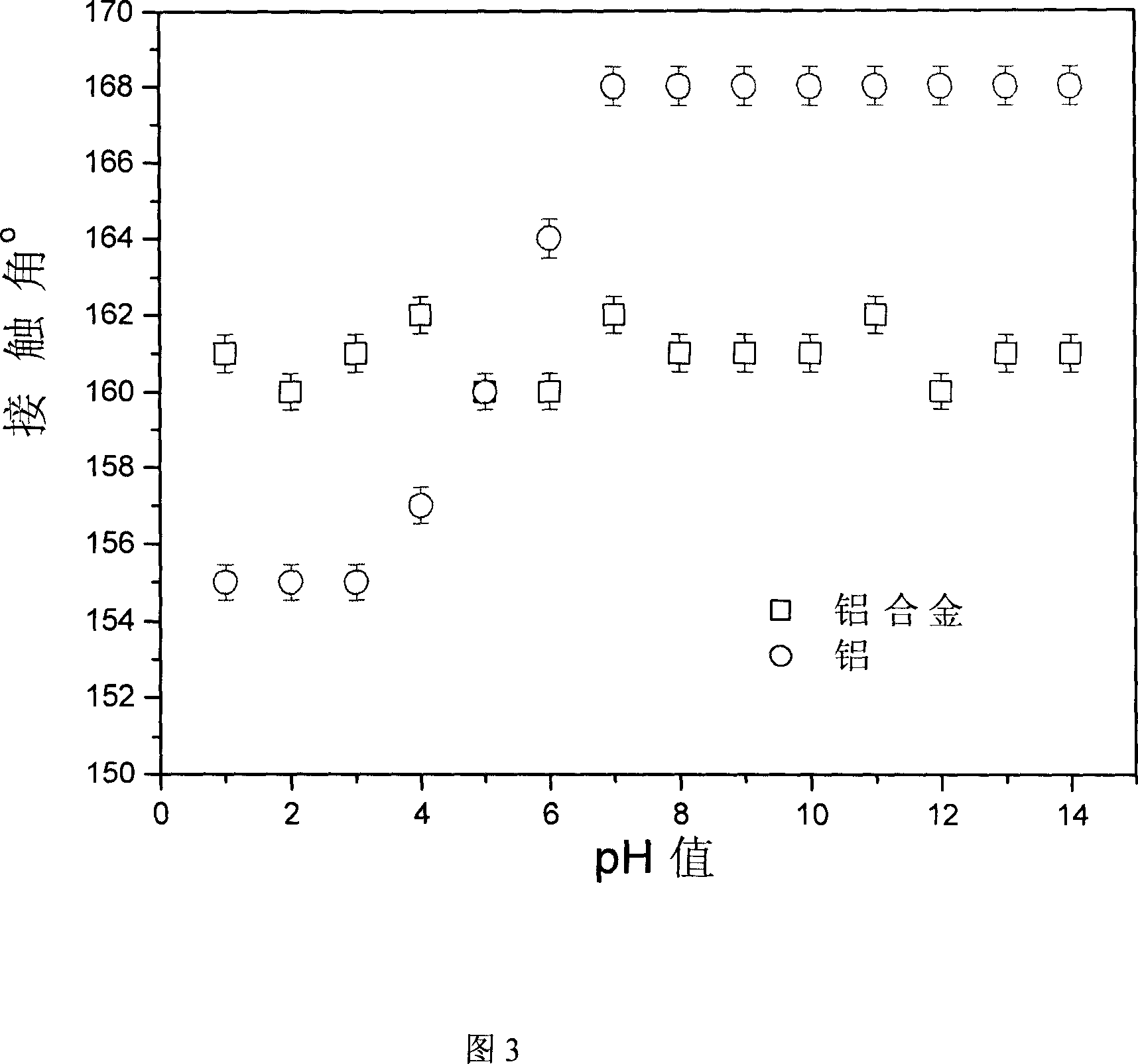

[0029] The scanning electron microscop...

Embodiment 2

[0032] 1. Use an ultrasonic cleaner to clean the aluminum and its alloy samples. The cleaning steps are: 1) put the aluminum and its alloy samples in acetone and clean them ultrasonically for 30 minutes to remove the grease on the samples; Put the good sample into 5wt% HCl solution for 10min to remove the oxide layer on the sample, 3) then wash it with deionized water for 5min, 4) finally dry it in a vacuum oven at 50°C for 30min before use;

[0033] 2. Put the processed aluminum and its alloy samples into 0.5M NaOH solution for oxidation for 2 hours; the oxidized aluminum and its alloy samples were washed with deionized water to remove excess NaOH solution on the surface of the oxidized sample, Then dry the oxidized sample in the air atmosphere at 100℃ for 1h;

[0034] 3. Add perfluorononane dropwise to the surface of the dried sample for chemical modification, and dry the oxidized sample in the air at 100°C for 1 hour in a drying oven to obtain a bionic superhydrophobic surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com