Superamphiphobic polymer material and its manufacturing method

A manufacturing method and super-amphiphobic technology, which can be used in polyurea/polyurethane coatings, anti-corrosion coatings, anti-fouling/underwater coatings, etc., can solve the problems of complex and time-consuming preparation process, and achieve the improvement of driving speed in degrees Celsius, reducing resistance, reducing the effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

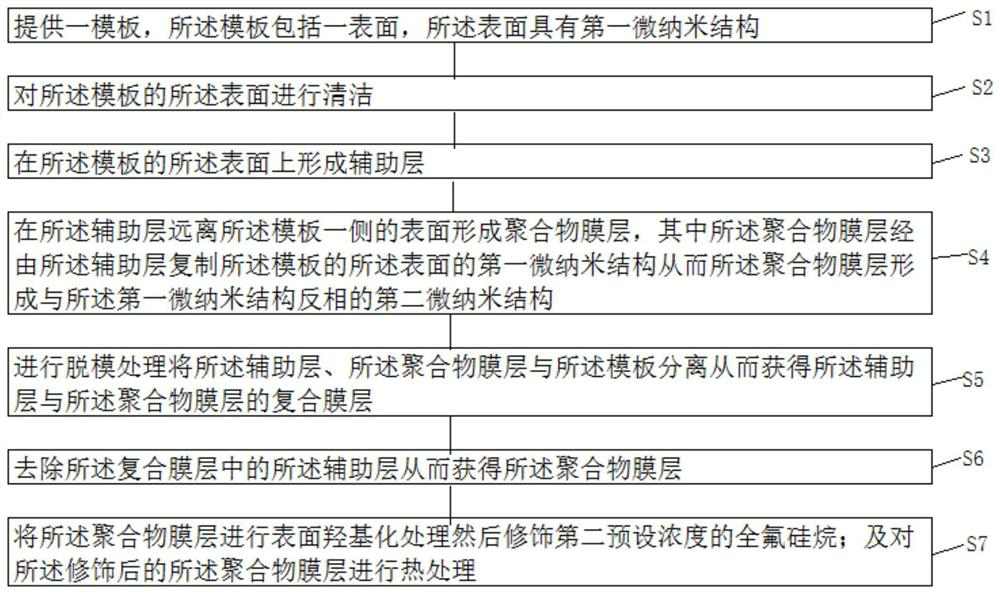

Method used

Image

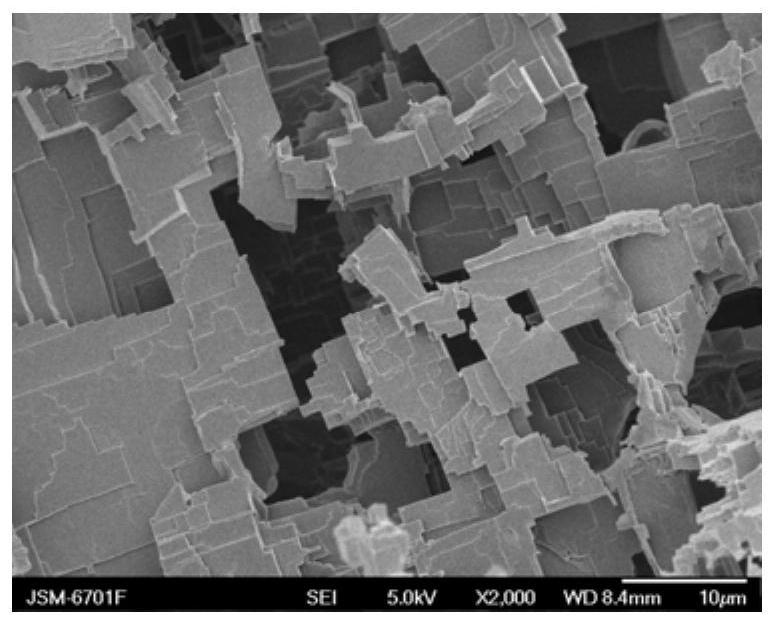

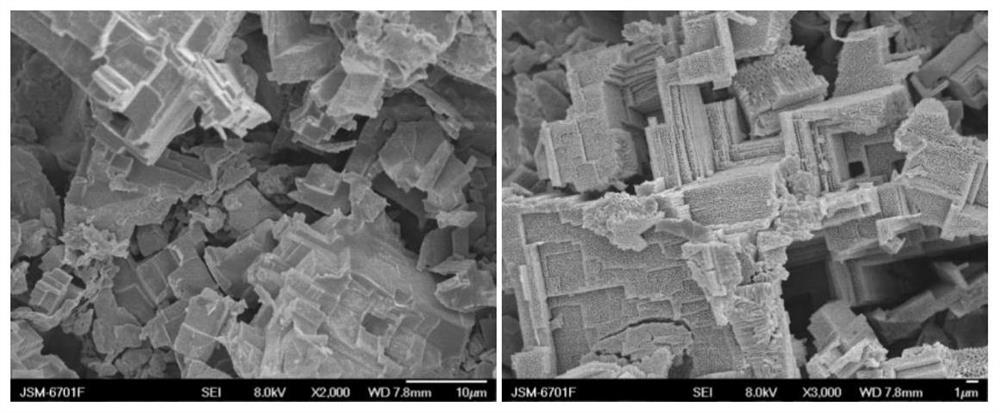

Examples

Embodiment Construction

[0046] The following will clearly and completely describe the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

[0047] Room temperature curing polymer materials are widely used in navigation, aerospace, pipeline transportation and many other fields, such as radar and aircraft casings, ships, submarine cabins, etc., and they also have important uses in daily life . According to the current literature, there is no simple and practical method for preparing various types of water, aqueous solutions, and various oils that are super-repellent at the same time. The superphobic polymer surface is a very important practical preparatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viewing angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com