Insulating shield and conductive rod assembly

A technology of insulating shield and conducting rod, applied in the direction of insulated cables, insulated conductors, insulators, etc., can solve the unsatisfactory performance of anti-creepage and anti-sparking, affect the reliable operation of electrical equipment, and increase the design and manufacturing workload. and other problems, to achieve the effect of good protection and electrical insulation, ingenious design and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

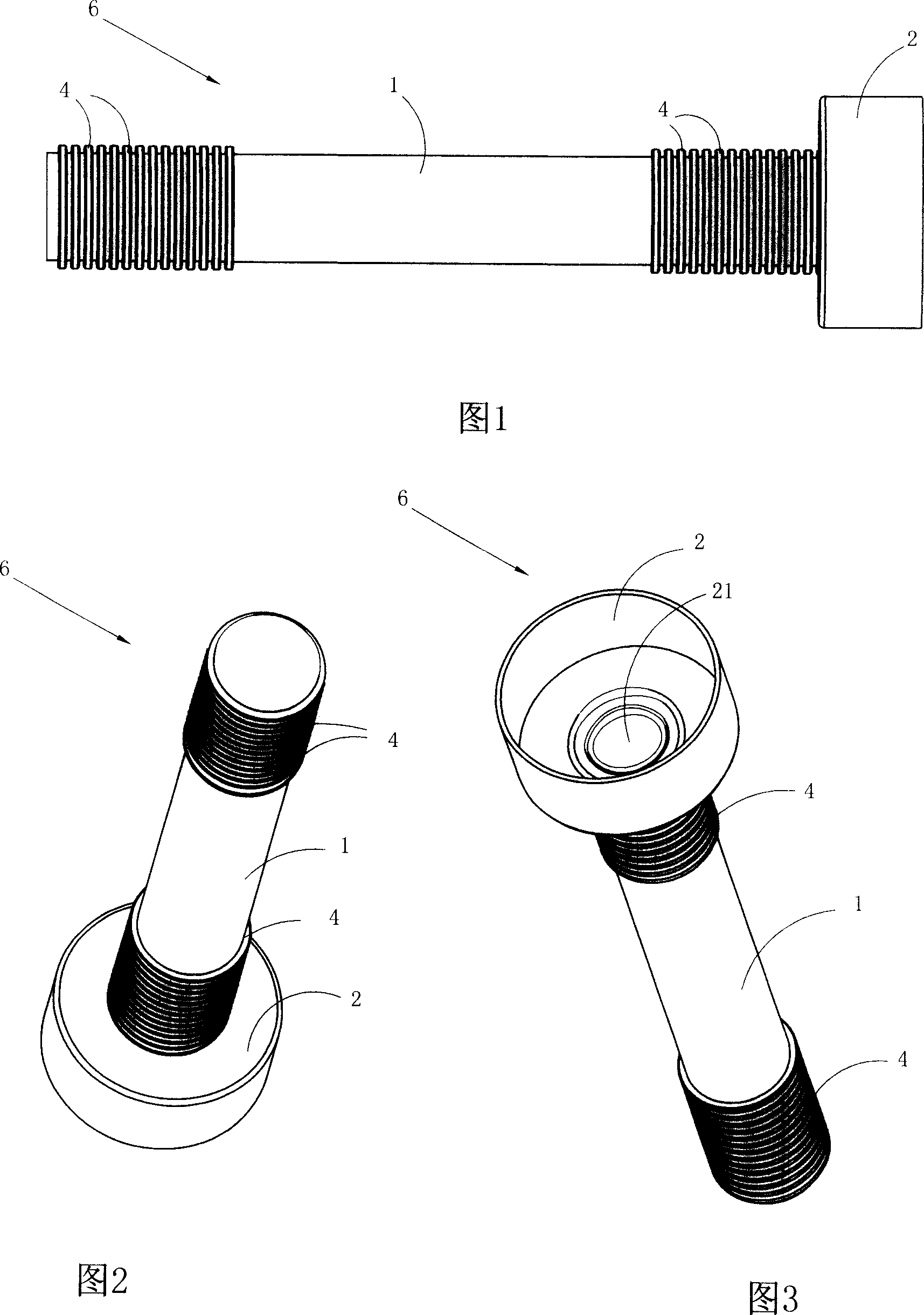

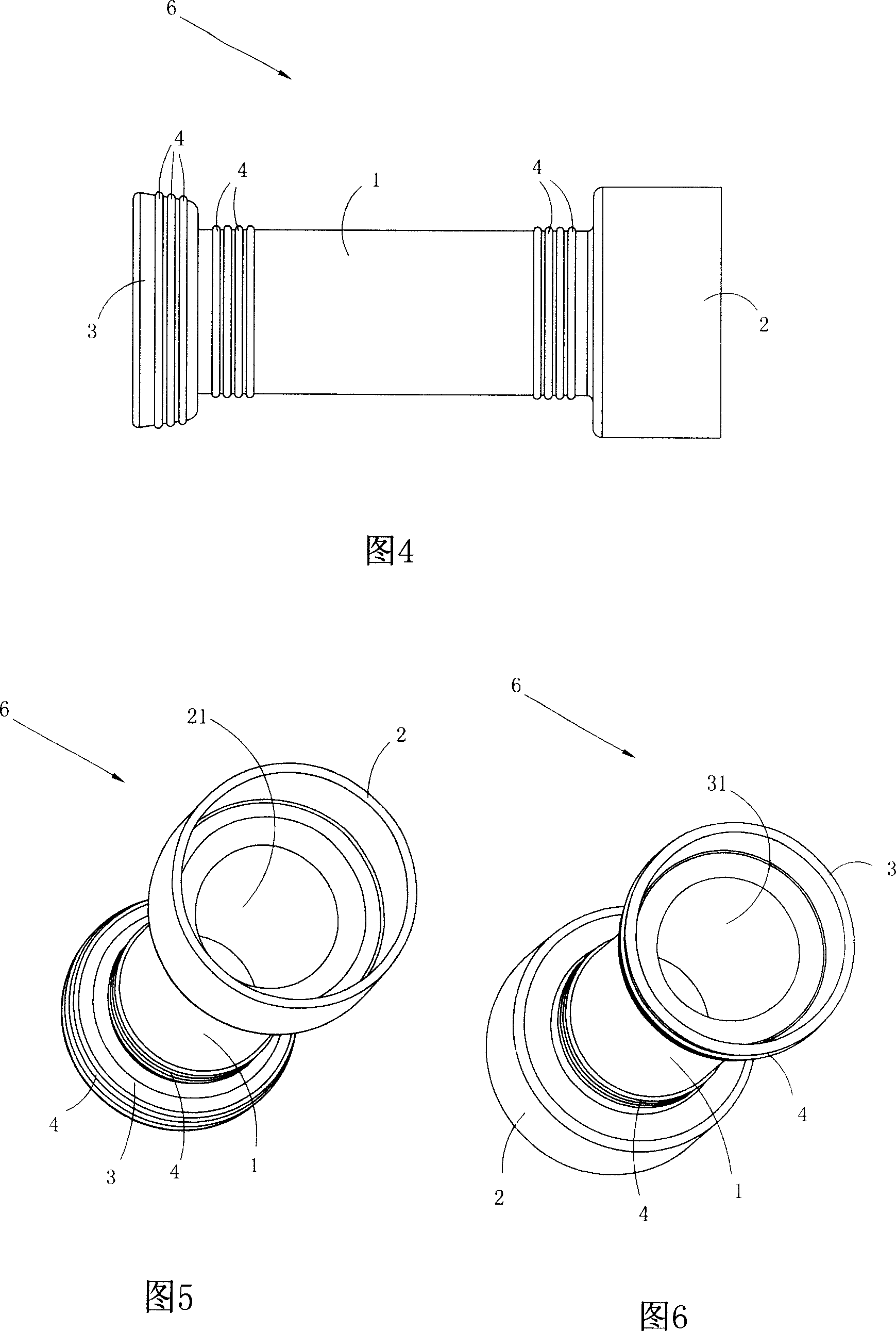

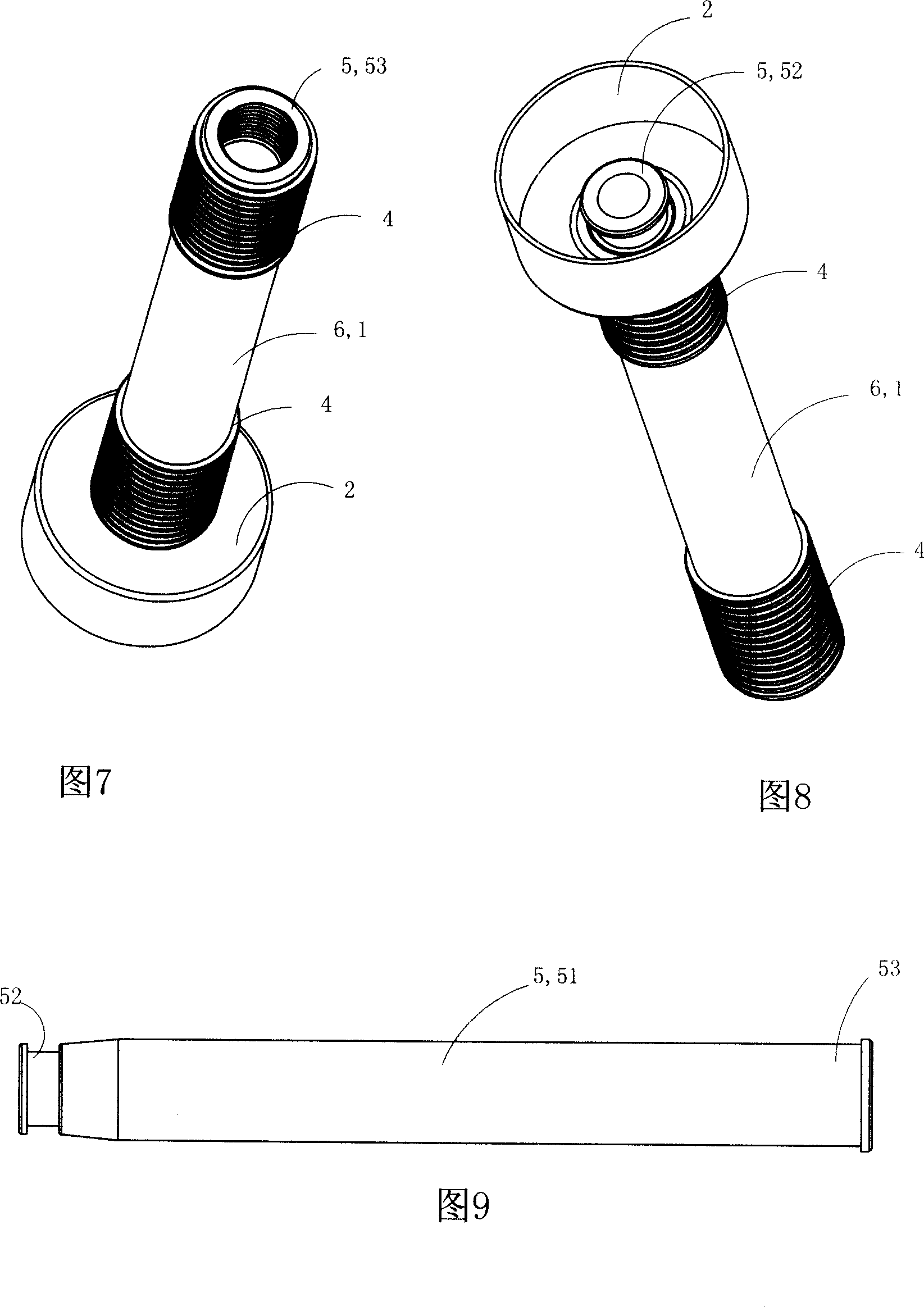

[0040] See Fig. 1 to Fig. 3, have shown the first kind of embodiment of the insulating cover 6 of the present invention, in this embodiment, described insulating cover 6 has hollow tubular insulating cover 1, and with insulating cover 1 side end Connected plug guard 2.

[0041] The basic shape of the plug protective cover 2 is a hollow cup with a round opening with a through hole 21 at the center of the end face connected to the insulating sleeve 1 at the bottom. The edges of the through holes 21 are fixedly connected to form one piece. The caliber of the plug shield 2, ie the maximum aperture of the cup-shaped body, is larger than the aperture of the insulating sleeve 1, so as to enclose the plug in the conductive rod assembly.

[0042] The outer surface of the insulating sleeve 1 is also provided with a plurality of anti-creepage rings 4, and the anti-creepage rings 4 are annular convex lines attached to the outer surface of the insulating sleeve 1. The anti-creepage rings ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com