A method for control of non-laminated DC motor with digital DC speed-regulating apparatus

A DC motor and DC speed regulation technology, which is applied in the field of CNC machine tools, can solve the problems of low insulation level, difficult to withstand rapid changes in current and voltage of digital electric transmission devices, and achieve the effect of protecting the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and all similar methods and similar changes of the present invention should be included in the protection scope of the present invention.

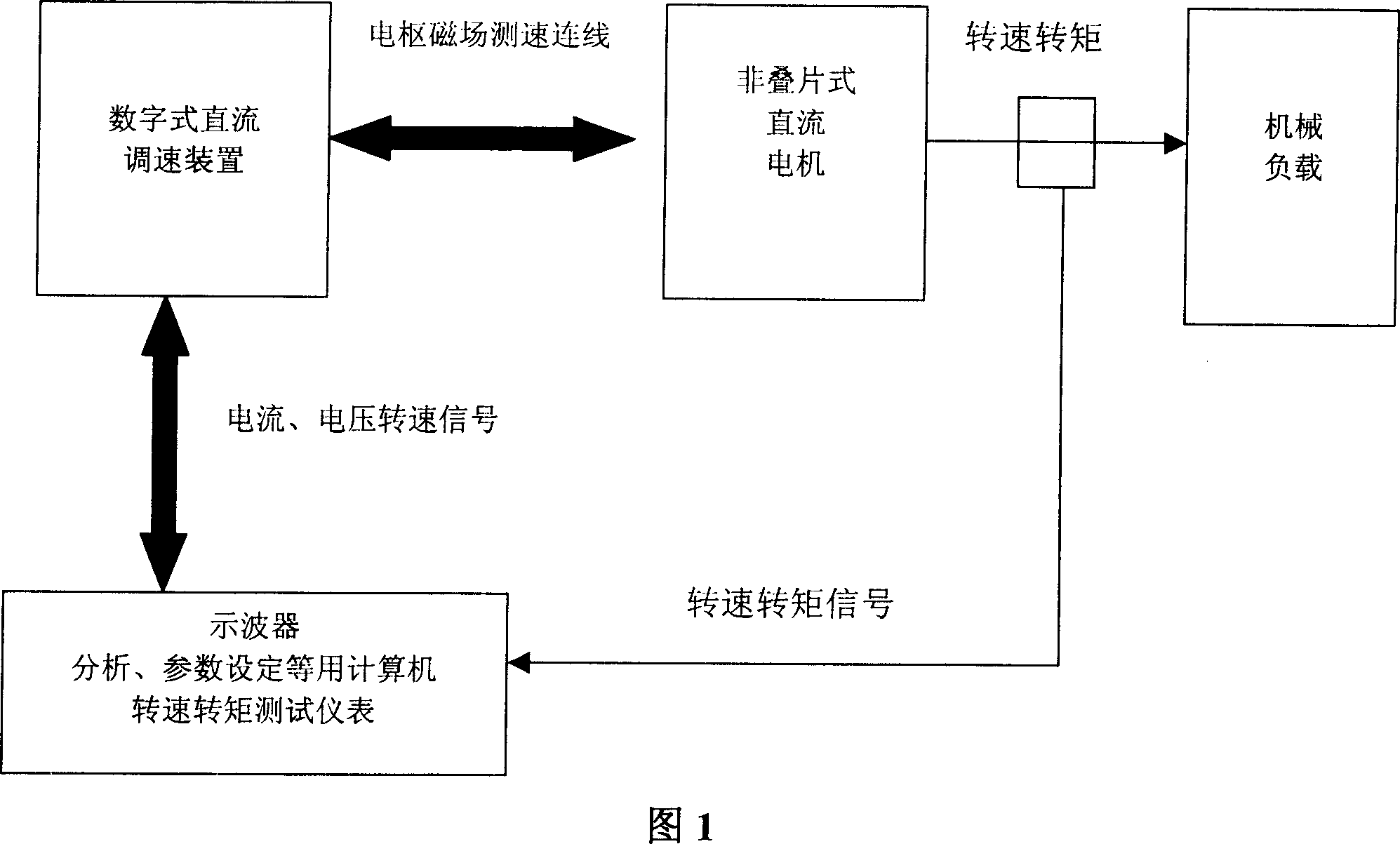

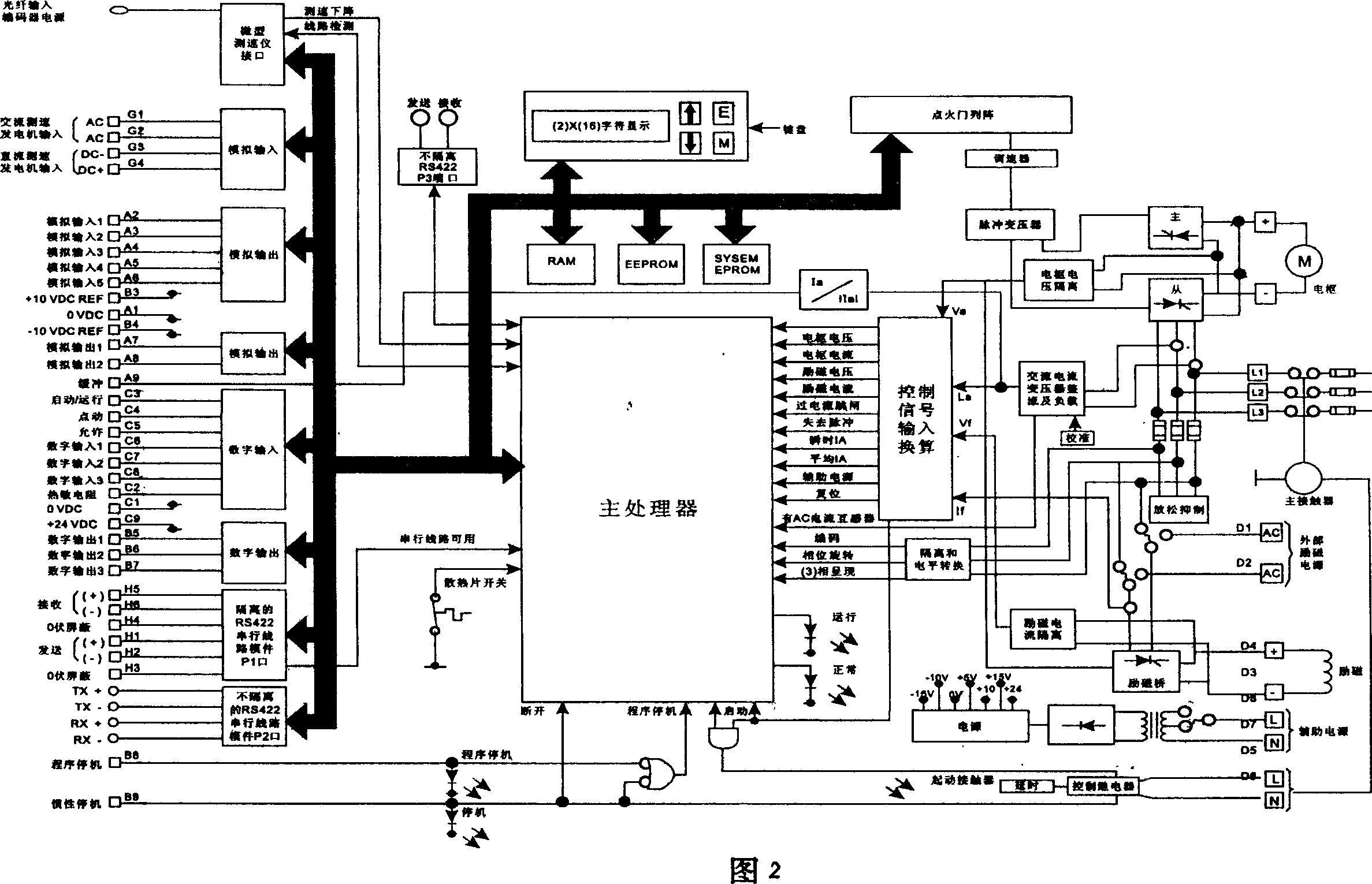

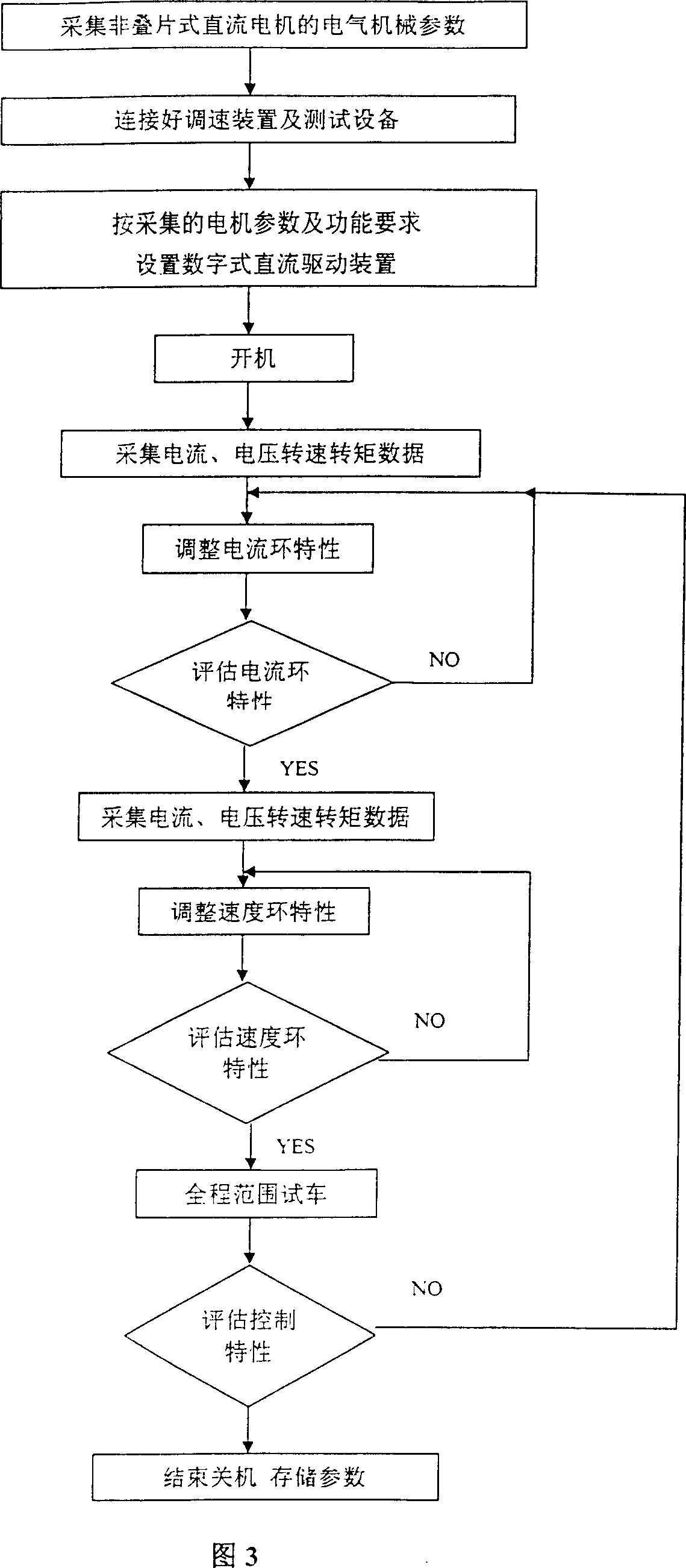

[0024] In view of the problems existing in the above-mentioned prior art, the present invention uses the actual state of the non-stacked DC motor, according to the speed-regulating mechanical characteristics of the non-stacked DC motor, the motor current-speed change process, and the required motor load change Large and other factors, the starting characteristics of the non-stacked DC motor are designed to have a sufficiently large starting torque and as small a starting current as possible when starting. Load characteristics, in the case of large load changes, the parameters of the speed P-I regulator and current regulator within...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com