Apparatus and method for the production of composite cigarette filters

A cigarette filter tip and combiner technology, which is applied in the field of rod devices, can solve problems such as unsatisfactory, and achieve the effect of high quality standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

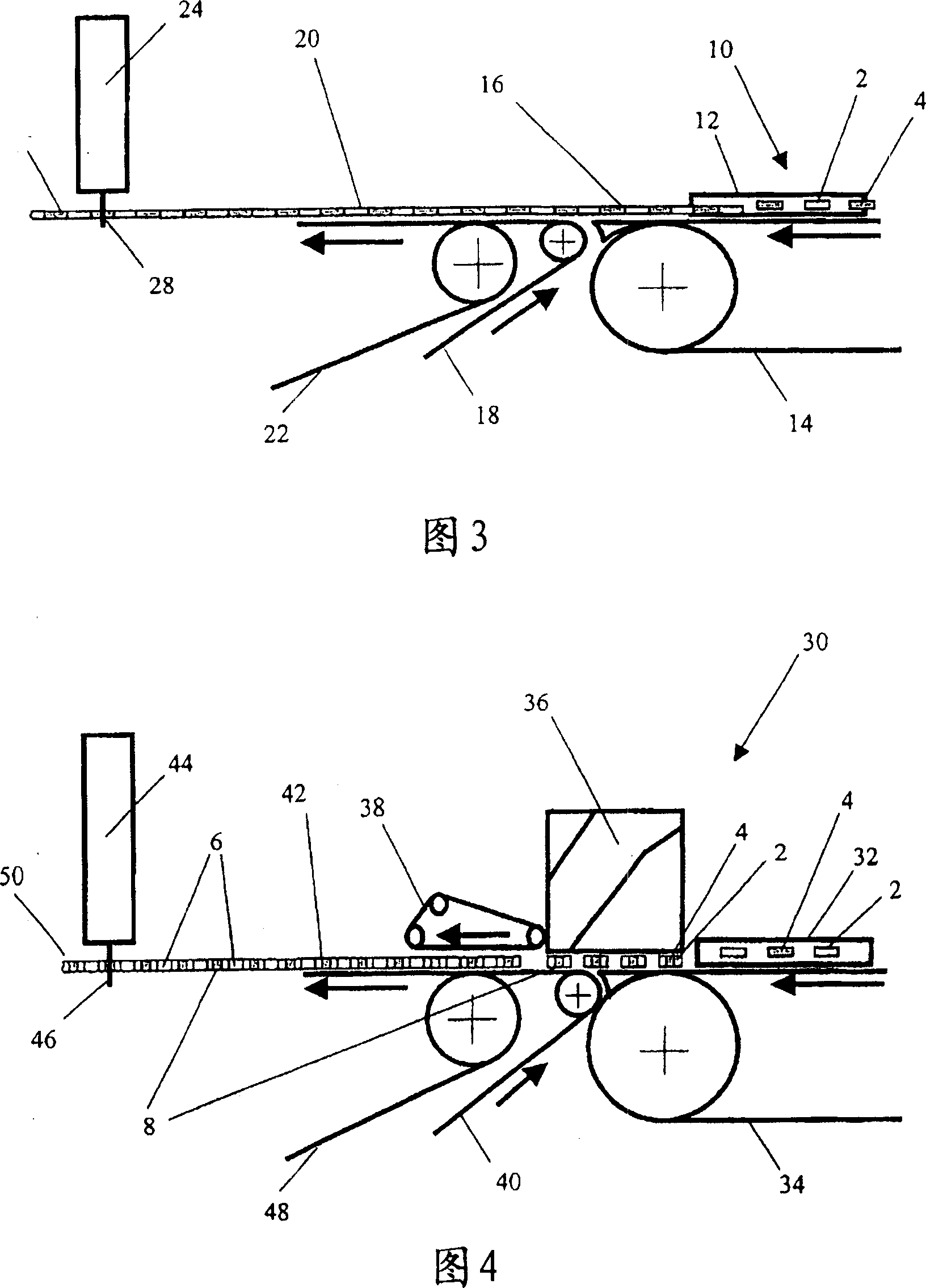

[0028] Figure 3 shows a known device for producing discrete composite filter rods, of the type sold under the model ND-3 by Japan Filter Technology Co., Ltd. (JT Group) and manufactured by Sanjo Machine Works Co., Ltd. of Japan . The known device comprises a combination device 10 comprising a delivery wheel 12 which arranges a plurality of different filter rod segments 2, 4 to a first endless belt in a preselected assigned configuration such as that shown in Fig. 1a Type conveyor 14. The different filter rod segments 2, 4 are conveyed from two or more bins or hoppers to the delivery wheel 12 by a series of conveyors not shown. When the filter rod segments 2 , 4 are conveyed to the first endless belt conveyor 14 , they are pushed against each other to form a continuous flow 16 . A first belt conveyor 14 conveys the abutting filter rod segments 2, 4 to the top of a continuously running paper web 18 drawn from a paper tray (not shown). The paper web 18 with at least a portion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com