Ceramifying composition for fire protection

A composition and ceramization technology, applied in the field of fire-retardant compositions, can solve the problems of endangering insulation, composition influence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

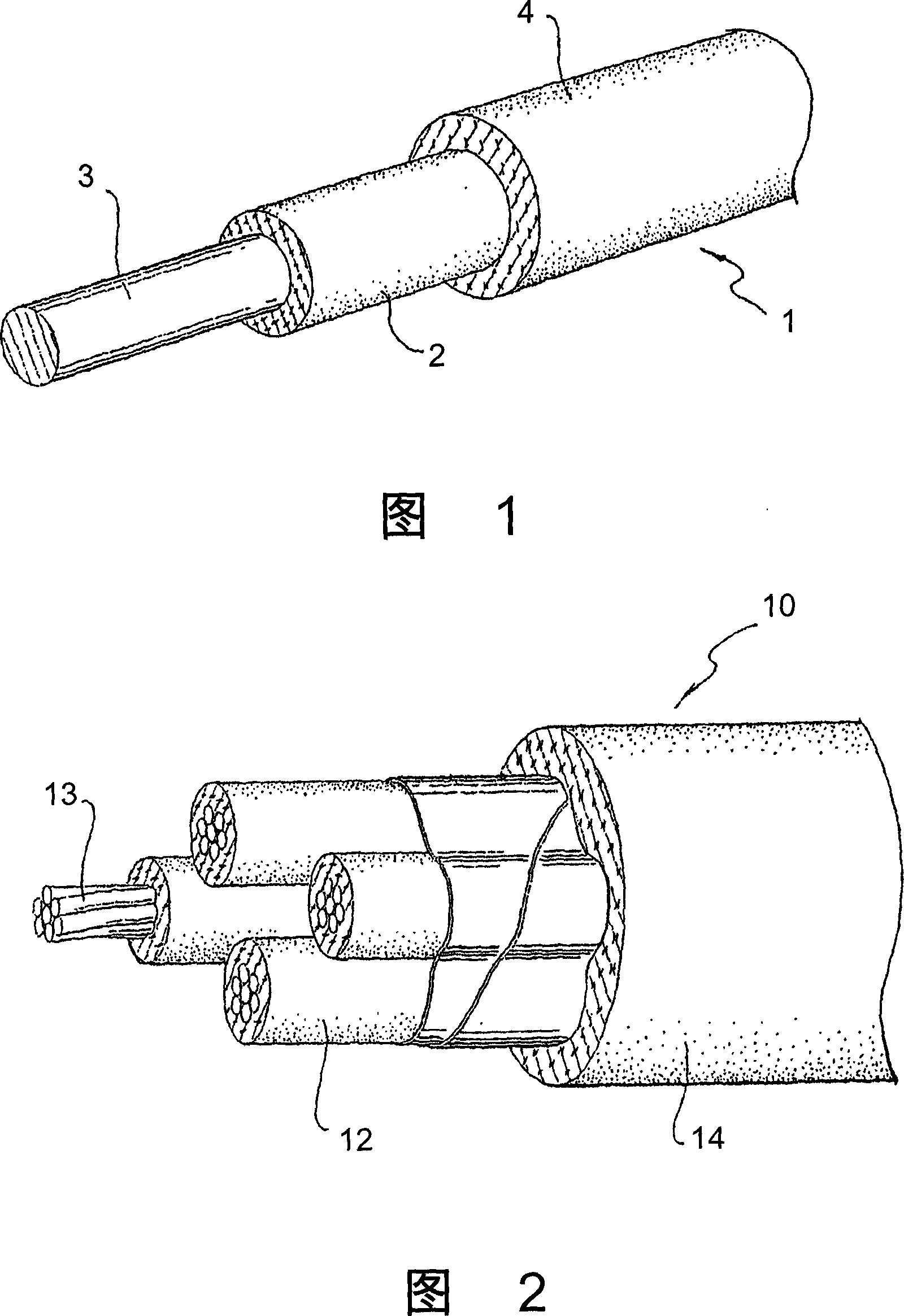

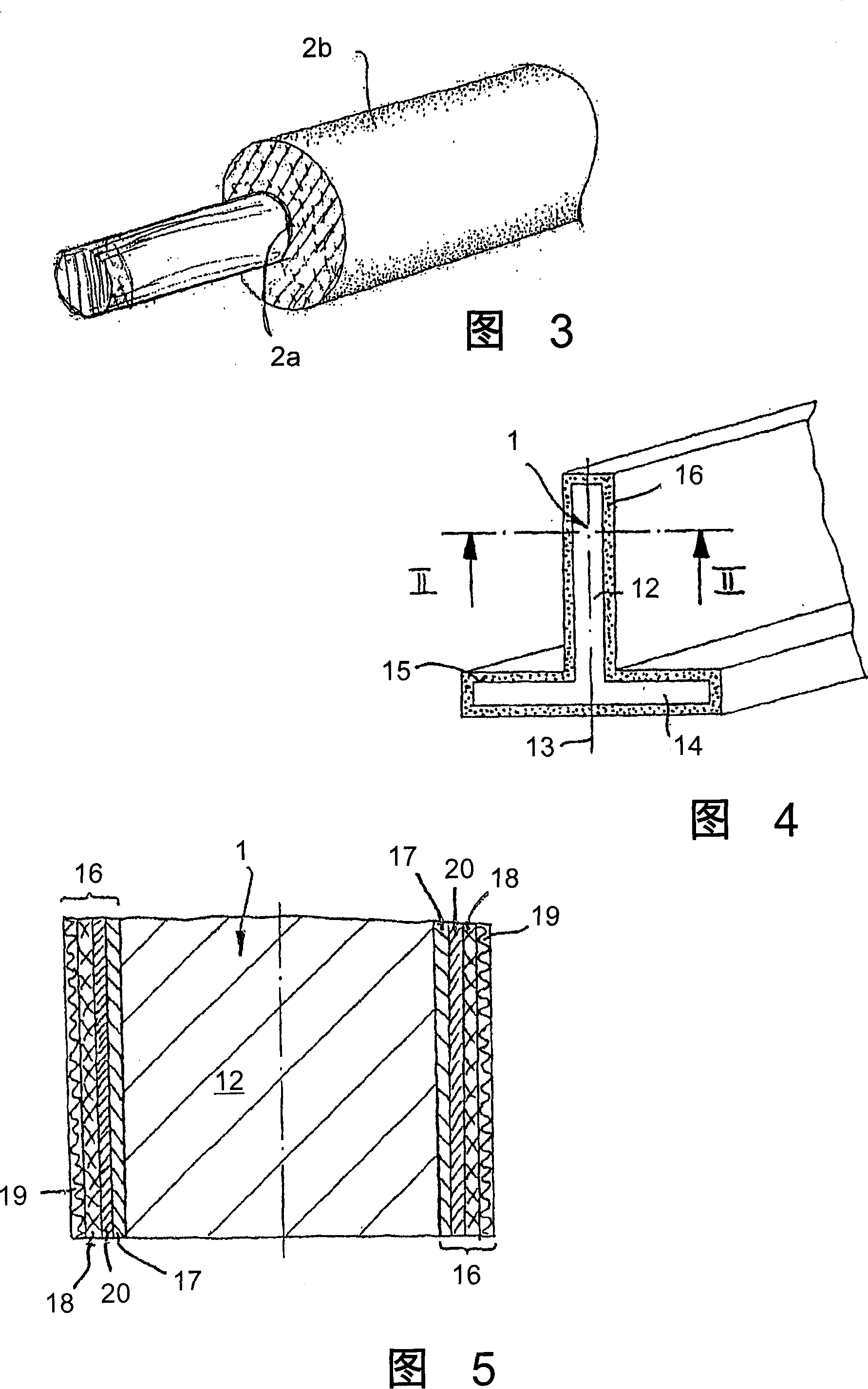

[0024] The ceramming compositions of the present invention provide fire-retardant properties at high temperatures caused by fires. The ceramming composition comprises a mineral silicate (optionally with other inorganic fillers) and an inorganic phosphate which, together with the mineral silicate, forms a bonded ceramic at high temperatures caused by a fire. At elevated temperatures resulting from a fire, the phosphate component initially forms a liquid phase, preferably at a temperature below the decomposition temperature of at least one of the other gas generating components. A dispersed gas phase is formed due to the decomposition of organic polymers and other components such as ammonium polyphosphate. When the temperature of the composition is raised above about 800°C, the composition forms a ceramic comprising an inorganic phosphate component and a mineral silicate. The inorganic phosphate and silicate components (especially the magnesium silicate in the silicate componen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com