Hydraulic directio machine

A steering machine and hydraulic technology, applied in the direction of hydraulic steering gear, etc., can solve the problems that the steering machine is difficult to achieve ergonomics, the angle of the steering wheel cannot be adjusted, and the steering force is increased, so as to simplify the design idea, the steering is easy and flexible, and the steering is reduced. The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

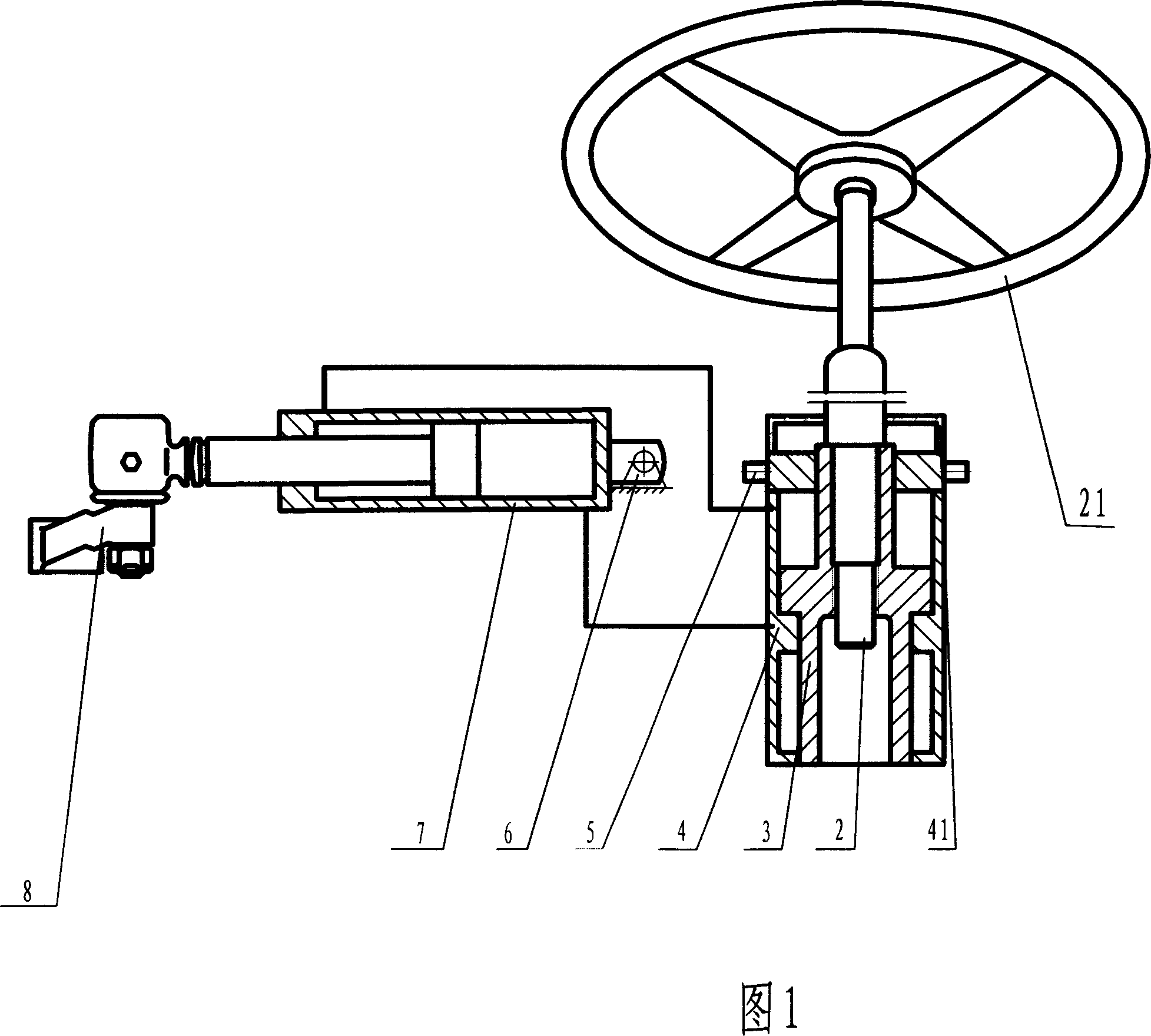

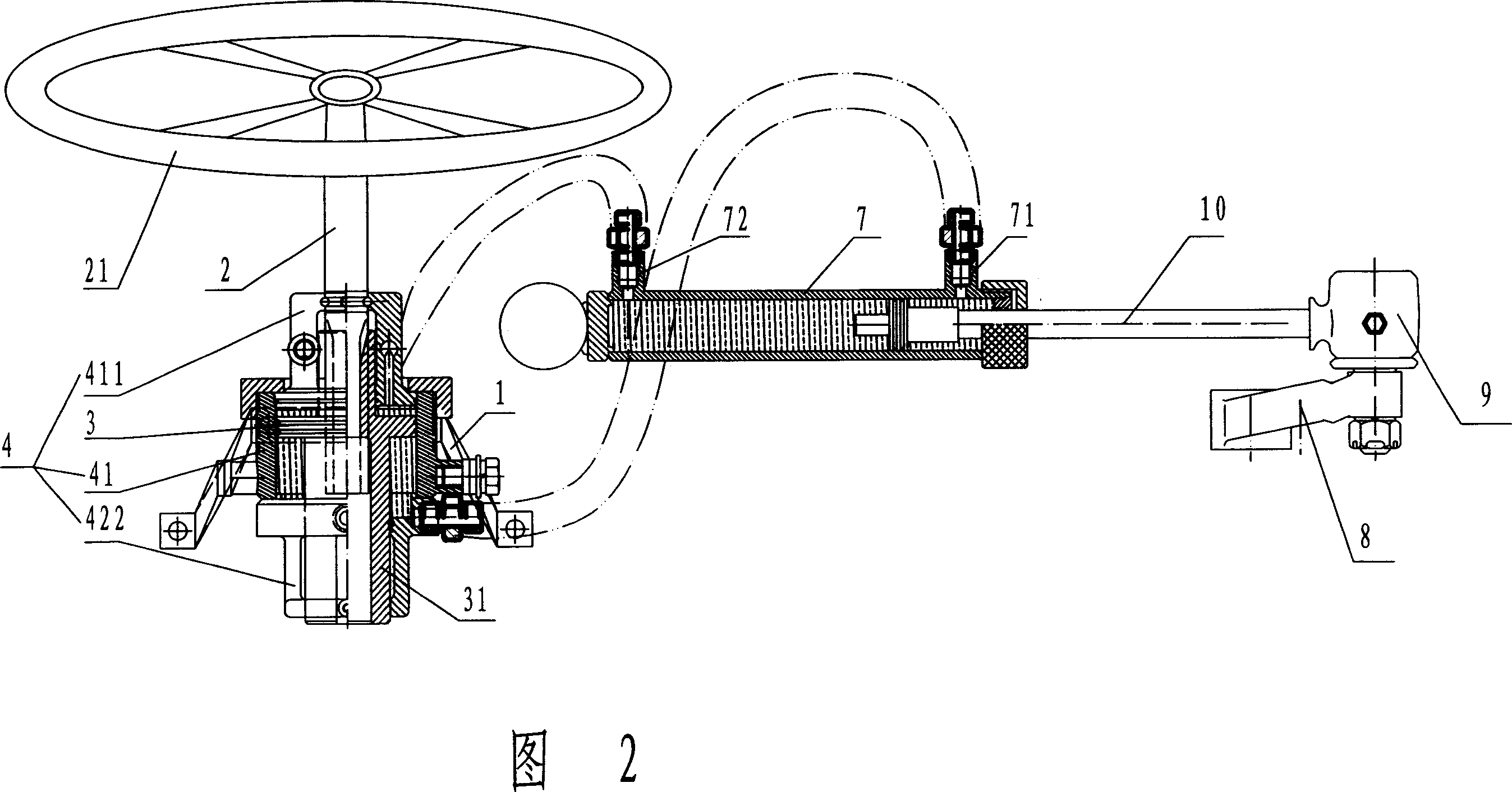

[0013] As shown in the drawings, the hydraulic steering machine of the present invention includes a steering shaft 2 and a steering wheel fixedly mounted on the top of the steering shaft 2 . The lower end of the steering shaft 2 is inserted in the drive cylinder 4 . The driving oil cylinder 4 is fixedly installed on the support 1, and is fixed on the vehicle frame or the chassis through the support 1. According to the installation position and space size of different vehicle models, the bracket 1 can adopt various structural forms.

[0014] The driving cylinder 4 includes a cylindrical cylinder body 41 with upper and lower end covers, and a driving cylinder piston 3 installed in the cylinder body 41 . The upper end cover 411 is fixedly installed on the upper end of the cylinder body 41 through the upper cover nut, and the lower end cover 422 is fixedly installed on the lower end of the cylinder body 41; A card slot, the annular card slot is clamped in the shaft hole of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com