Piezoelectric ultrasound motor

A piezoelectric ultrasonic and motor technology, which is applied in circuits, piezoelectric devices/electrostrictive devices, electrical components, etc., and can solve the problems of increased drive system size and complex manipulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

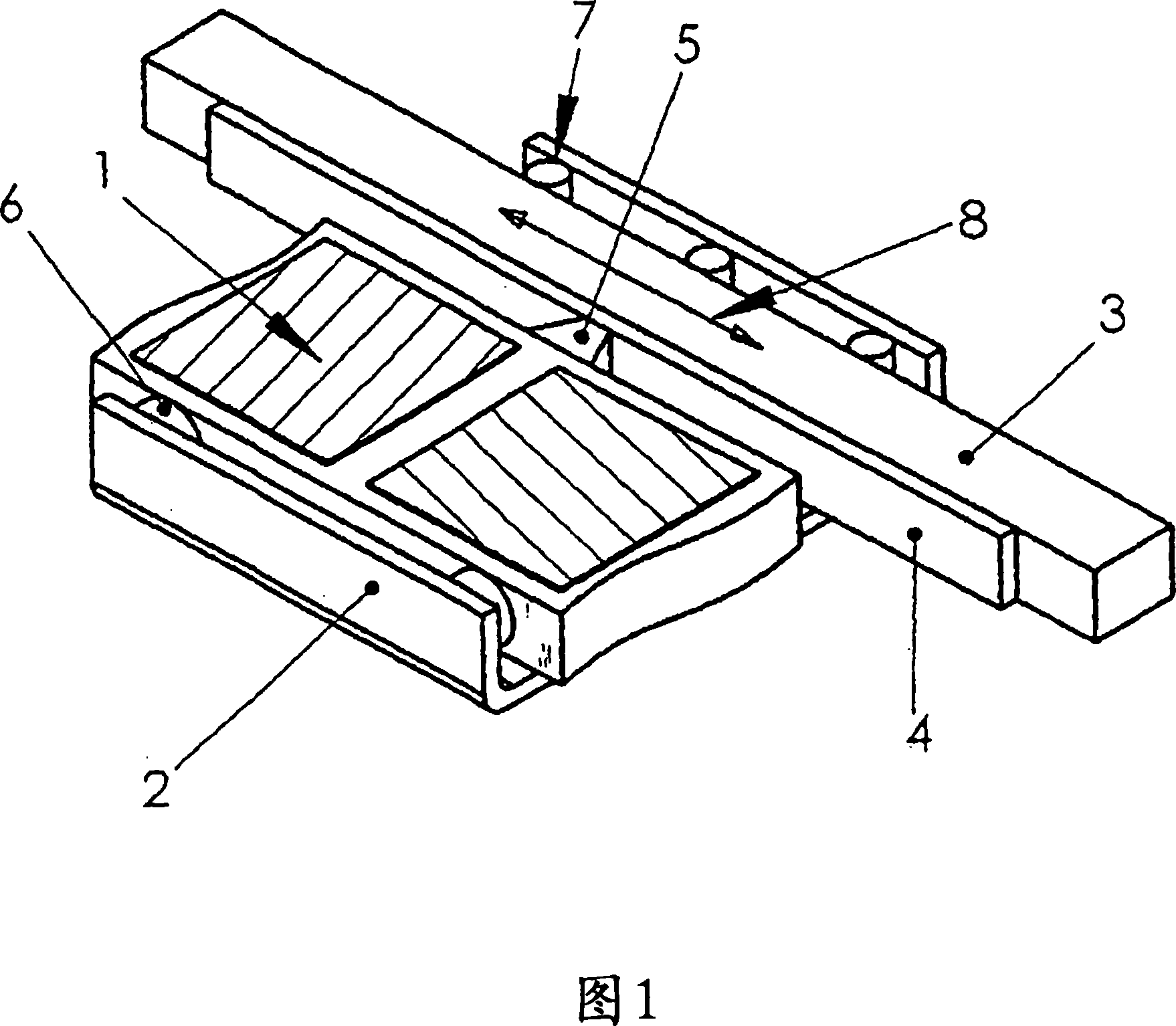

[0024] The piezoelectric ultrasonic motor of the present invention includes a piezoelectric oscillator 1 provided in a housing 2, and an element 3 (refer to FIG. 1 ) to be moved with a friction belt 4 attached thereto. Piezoelectric oscillator 1 with friction element 5 is elastically excited relative to friction band 4 by means of pressure element 4 . The element to be moved 3 is fastened to a bearing seat 7 in the motor housing 2 so that it can move in the direction indicated by the arrow 8 .

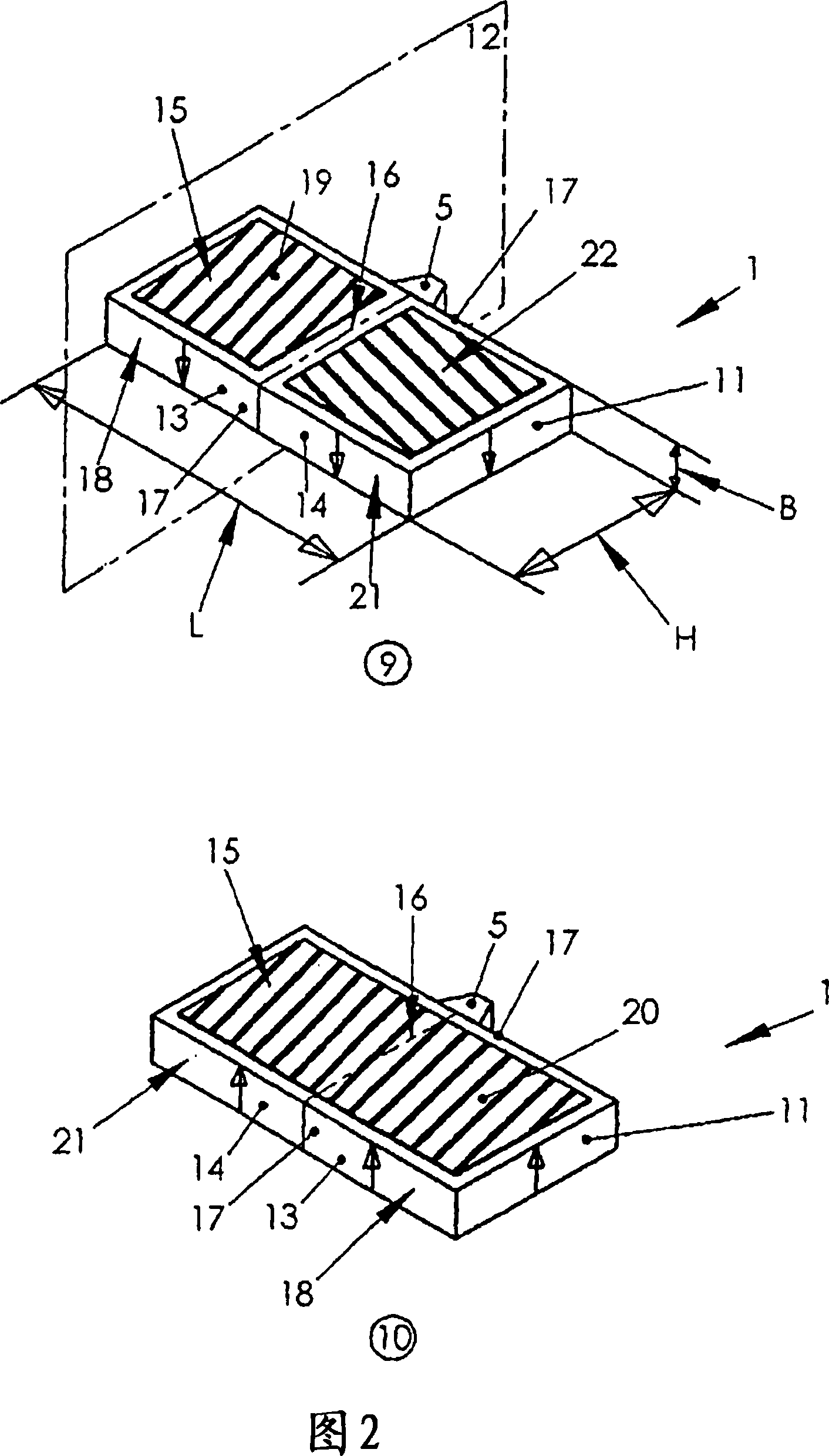

[0025] In FIG. 2, items 9, 10 are plan and bottom views of oscillator 1, respectively. The oscillator 1 is configured as a piezoelectric plate 11 of length L, height H, and width B, and is divided into two equal parts 13 , 14 by a dividing plane 12 .

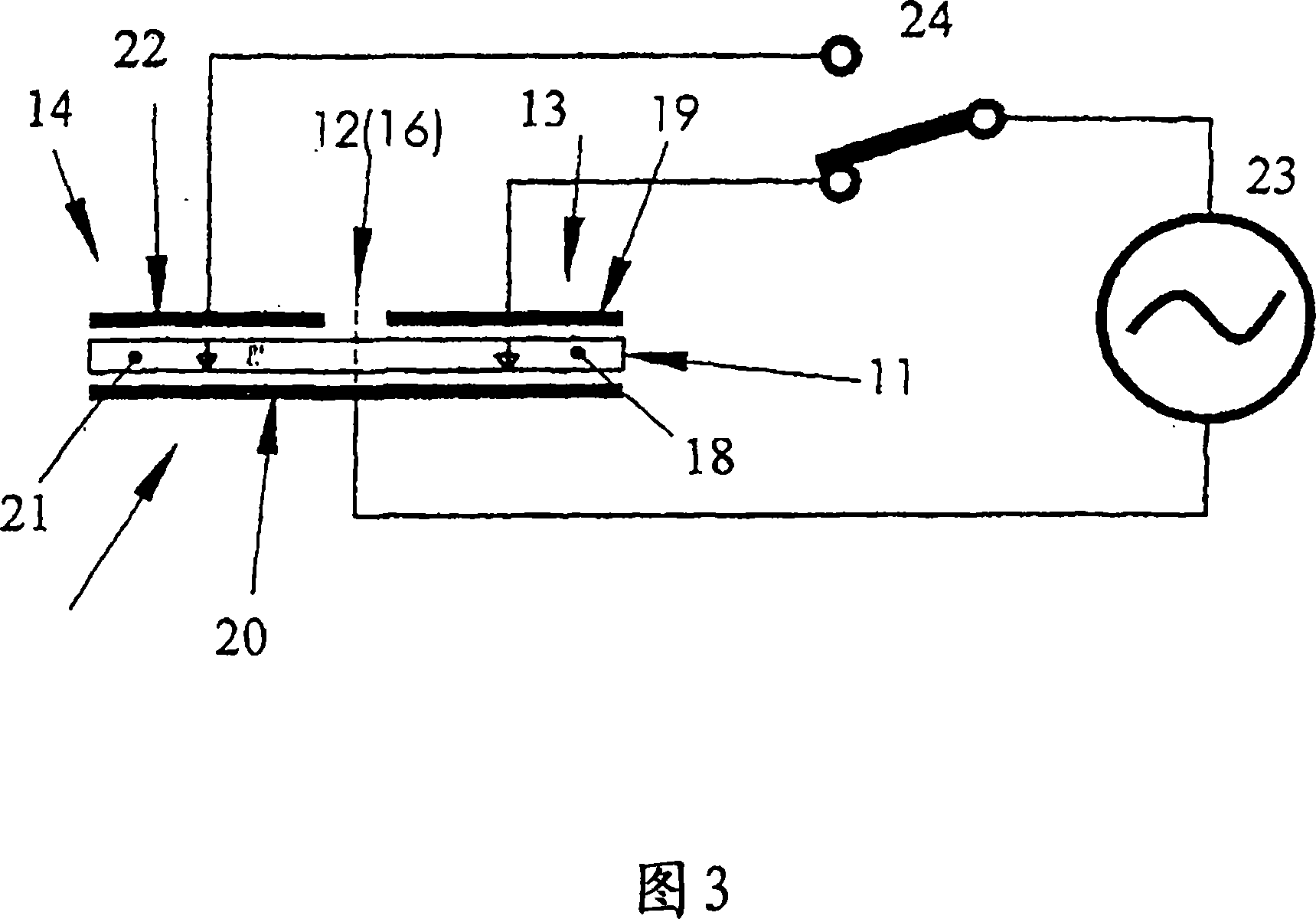

[0026] The dividing plane 12 passes through the center of the oscillator length L and is perpendicular to the large side 15 of the oscillator. The trace 16 of the dividing plane 12 is indicated by the dashed line on the oscillator 1 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com