Cutting device

A cutting device, cutting edge technology, used in metal processing machinery parts, maintenance and safety accessories, measuring/indicating equipment, etc., can solve the problems of identifying cutting inserts, lack of flexibility, wiring difficulties, etc., to achieve a clear contrast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

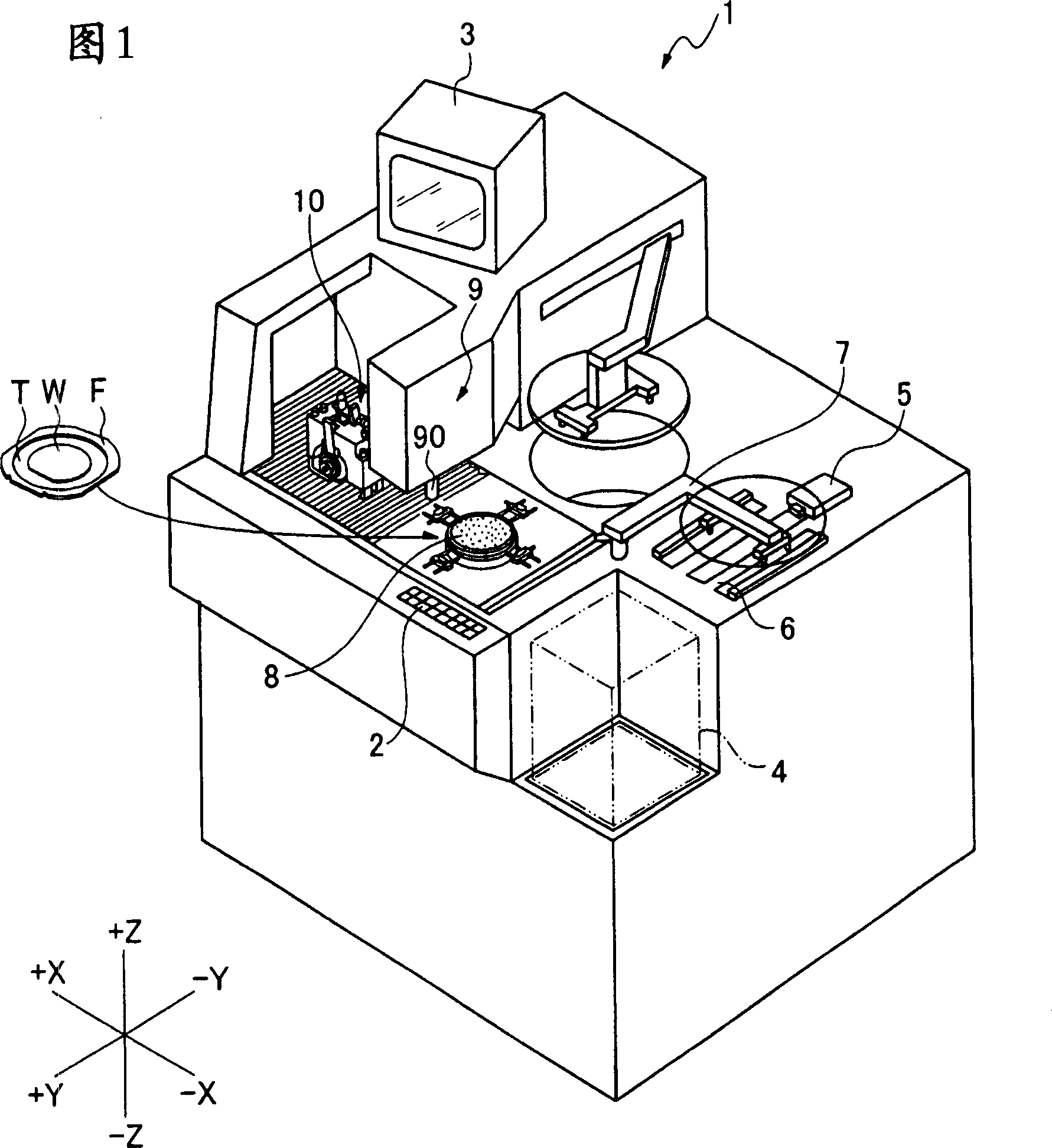

[0031] The cutting device 1 shown in FIG. 1 is a device for cutting a workpiece to be divided into individual chips, and an operation unit 2 for an operator to input various information such as cutting conditions is provided on the front side. In addition, a display unit 3 capable of displaying various information including images is provided on the upper part of the device.

[0032] An example of a workpiece to be cut includes a wafer W shown in FIG. 1 on which a plurality of devices are formed. When cutting the wafer W, the wafer W is attached to the tape T, and the ring-shaped frame F is also attached to the tape T, so that the wafer W and the frame F are integrated through the tape T. In this way, a plurality of wafers W supported by the frame F via the tape T are accommodated in the wafer cassette 4 .

[0033] On the −Y direction side of the wafer cassette 4 is disposed a transport unit 5 that has functions of transporting uncut wafers W from the wafer cassette 4 and sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com