Secondary-fluid mixing method and mixer for coagulating procedure

A technology of mixing equipment and secondary flow, applied in separation methods, chemical instruments and methods, flocculation/sedimentation water/sewage treatment, etc. Ideal and other problems, to achieve the effect of uniform flow field, simple structure and good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

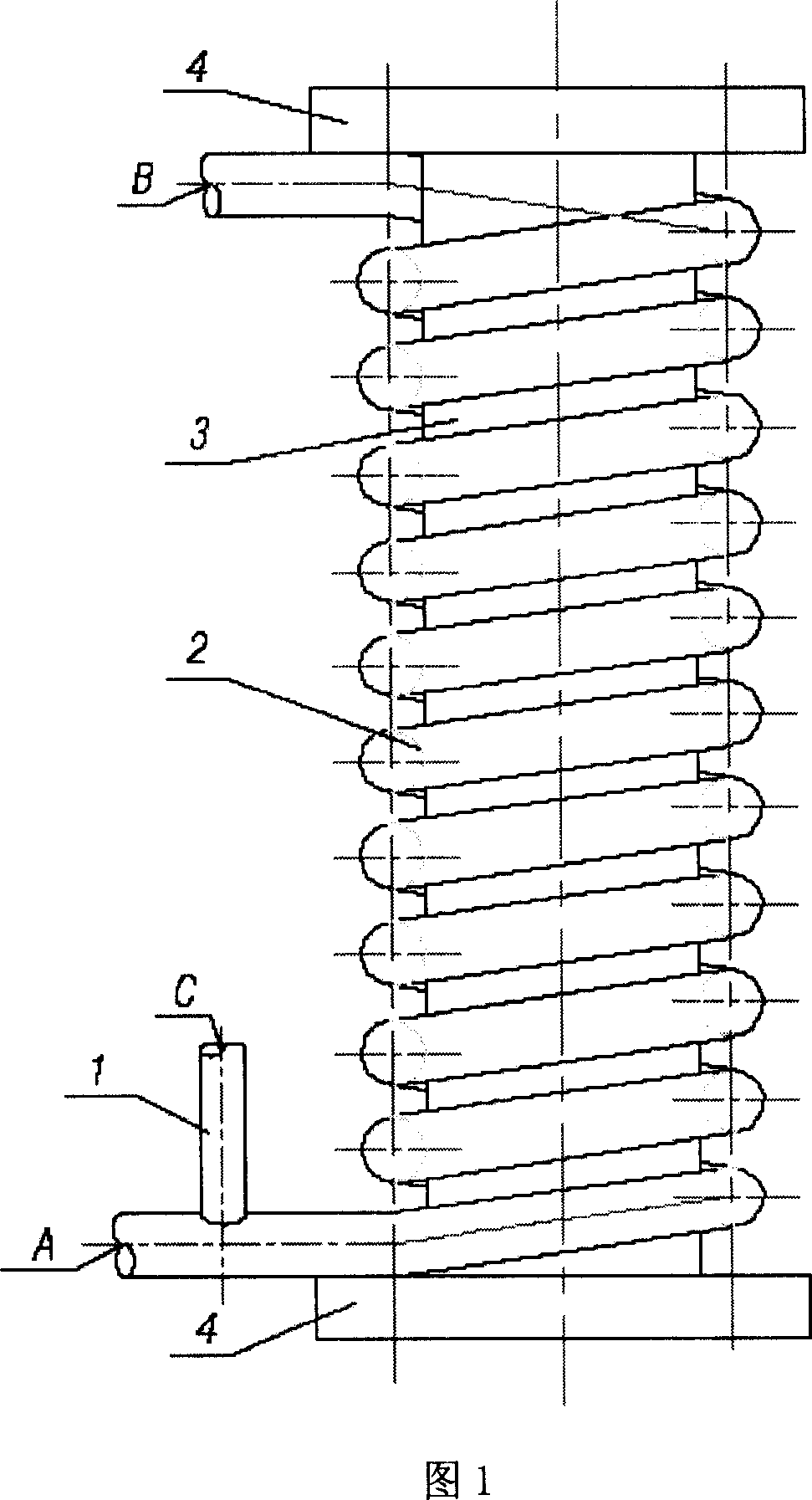

[0017] In Fig. 1, the secondary flow mixing equipment in the present invention is formed by winding the soft secondary flow pipe 2 on the cylinder 3, and the two ends of the cylinder are connected with baffles 4 to prevent the secondary flow pipe 2 from the cylinder The end of body 3 falls off. The raw water to be treated enters the mixing equipment from the water inlet A, mixes with the coagulant entering from the dosing port C, enters the secondary flow pipe 2, and finally flows out from the water outlet B to enter the flocculation stage of the coagulation reaction. The connection mode between water inlet A, water outlet B and chemical feeding port C and other pipelines can be flange connection or thread connection.

Embodiment 2

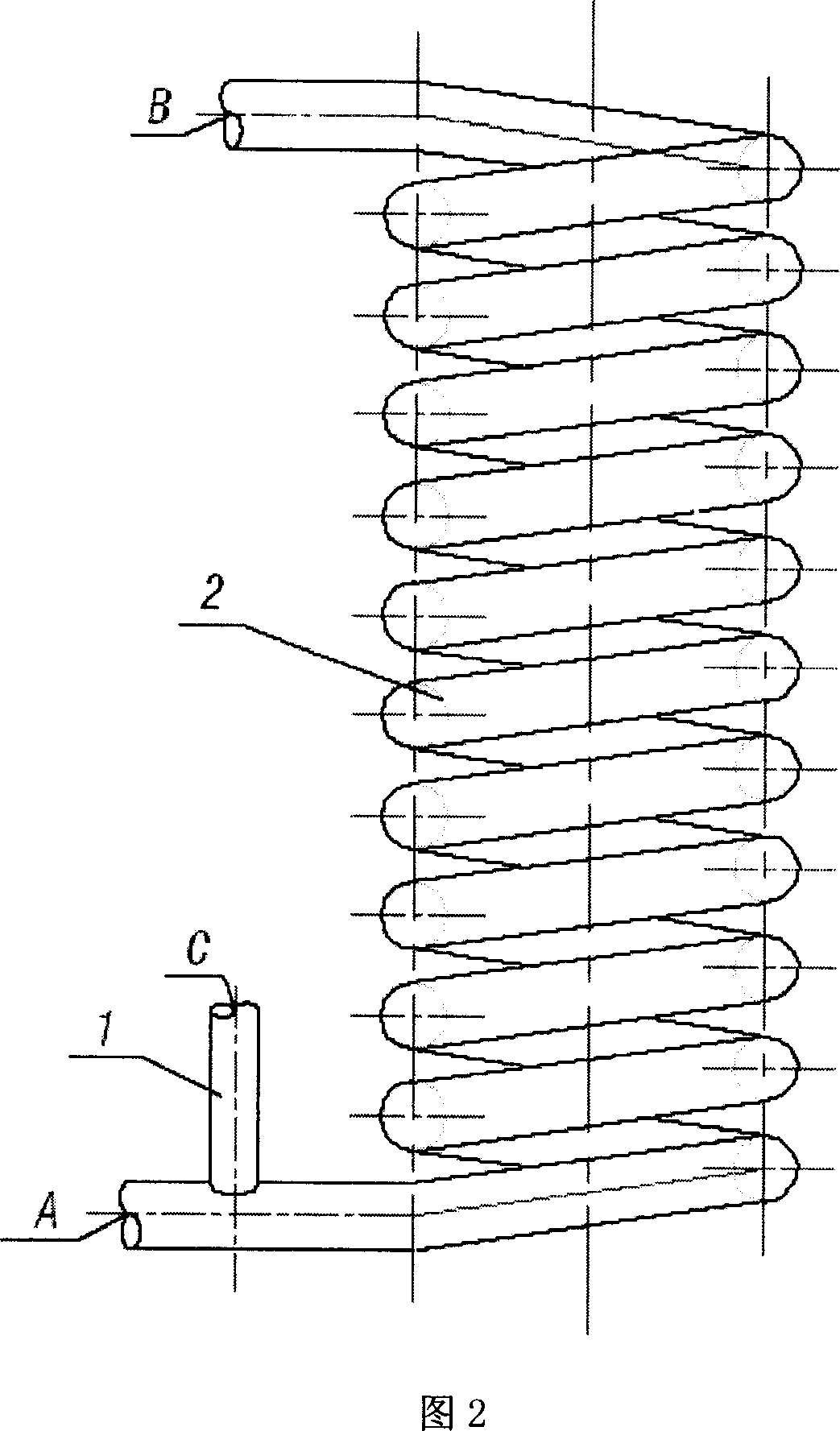

[0019] In Fig. 2, the secondary flow mixing device in the present invention is composed of a hard secondary flow pipe 2 helically wound. The raw water to be treated enters the mixing equipment from the water inlet A, mixes with the coagulant entering from the dosing port C, enters the secondary flow pipe 2, and finally flows out from the water outlet B to enter the flocculation stage of the coagulation reaction. The connection mode between water inlet A, water outlet B and chemical feeding port C and other pipelines can be flange connection or thread connection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com